Production method for glasses lens, marking device, marking system, glasses lens

A technology for spectacle lenses and manufacturing methods, applied in the directions of glasses/goggles, manufacturing tools, instruments, etc., can solve the problems of difficult observation and reduced visibility, and achieve excellent appearance, prevent defective products from leaving the factory, and high energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

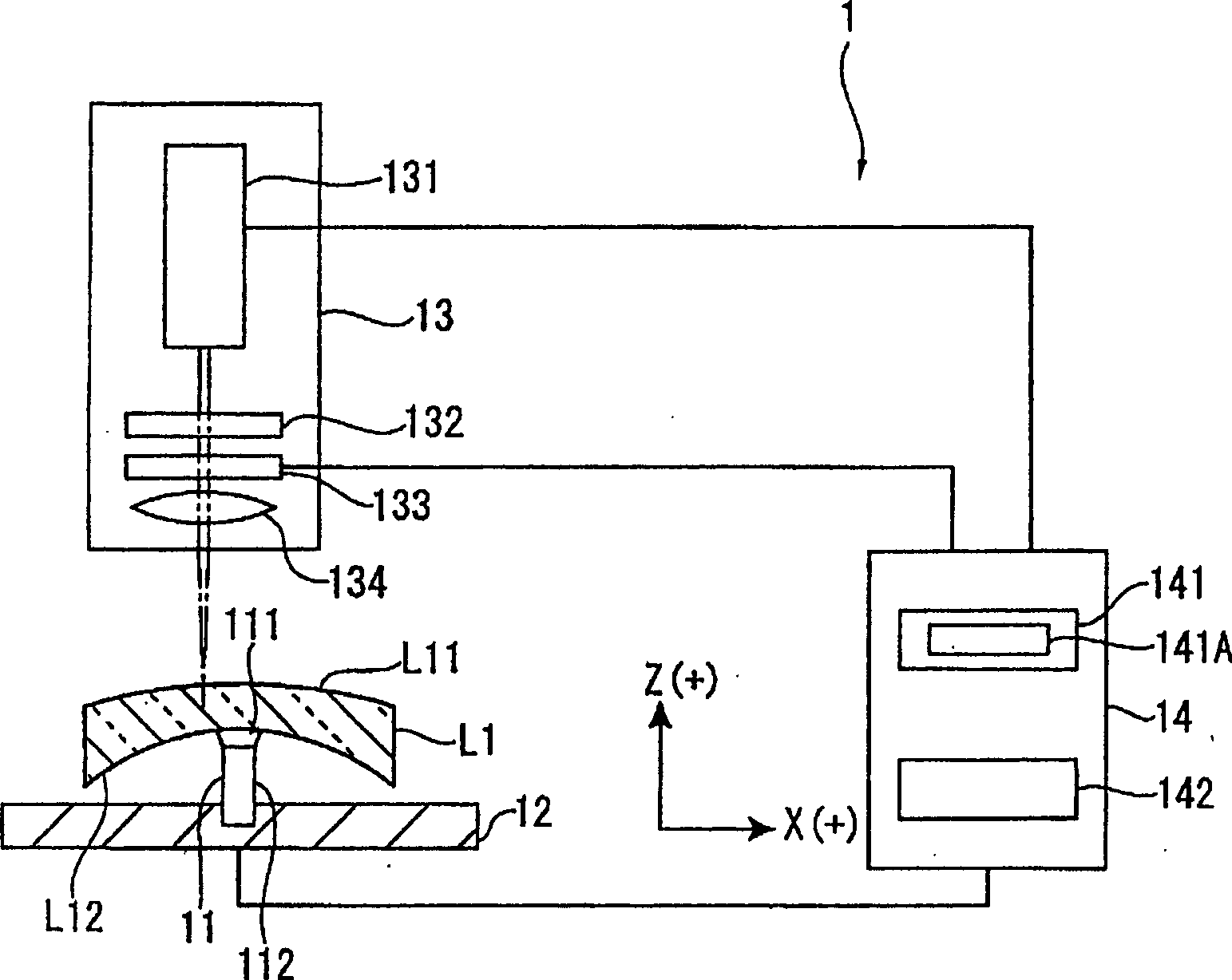

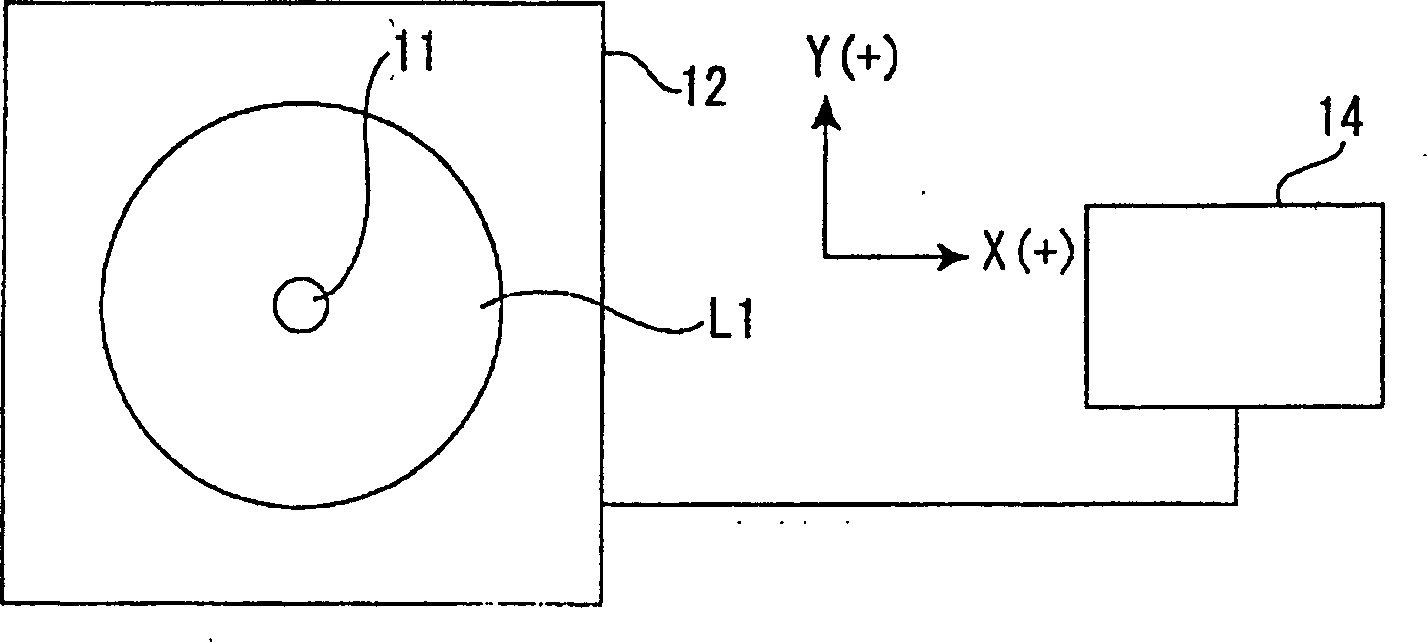

[0087]FIG. 1 is a schematic configuration diagram showing one embodiment of a marking device 1 for spectacle lenses L1 according to the present invention.

[0088] In this marking device 1 , laser light is condensed inside the spectacle lens L1 to generate a modified portion inside the spectacle lens L1 to form a mark 10A (see FIG. 2 ).

[0089] This marking device 1 has: a holding unit 11 holding the spectacle lens L1; a stage 12 as a moving unit capable of moving the holding unit 11 holding the spectacle lens L1; a laser output unit 13 for emitting laser light; and a control unit 14. .

[0090] The holding part 11 sticks and holds by making the part which contacts the concave surface L12 side of the spectacle lens L1 into a vacuum.

[0091] The holding unit 11 has a suction cup 111 for suctioning the concave surface L12 of the spectacle lens L1 , and a cylindrical portion 112 formed with a vacuum path communicating with the suction cup 111 to vacuum the inside of the suctio...

no. 2 approach

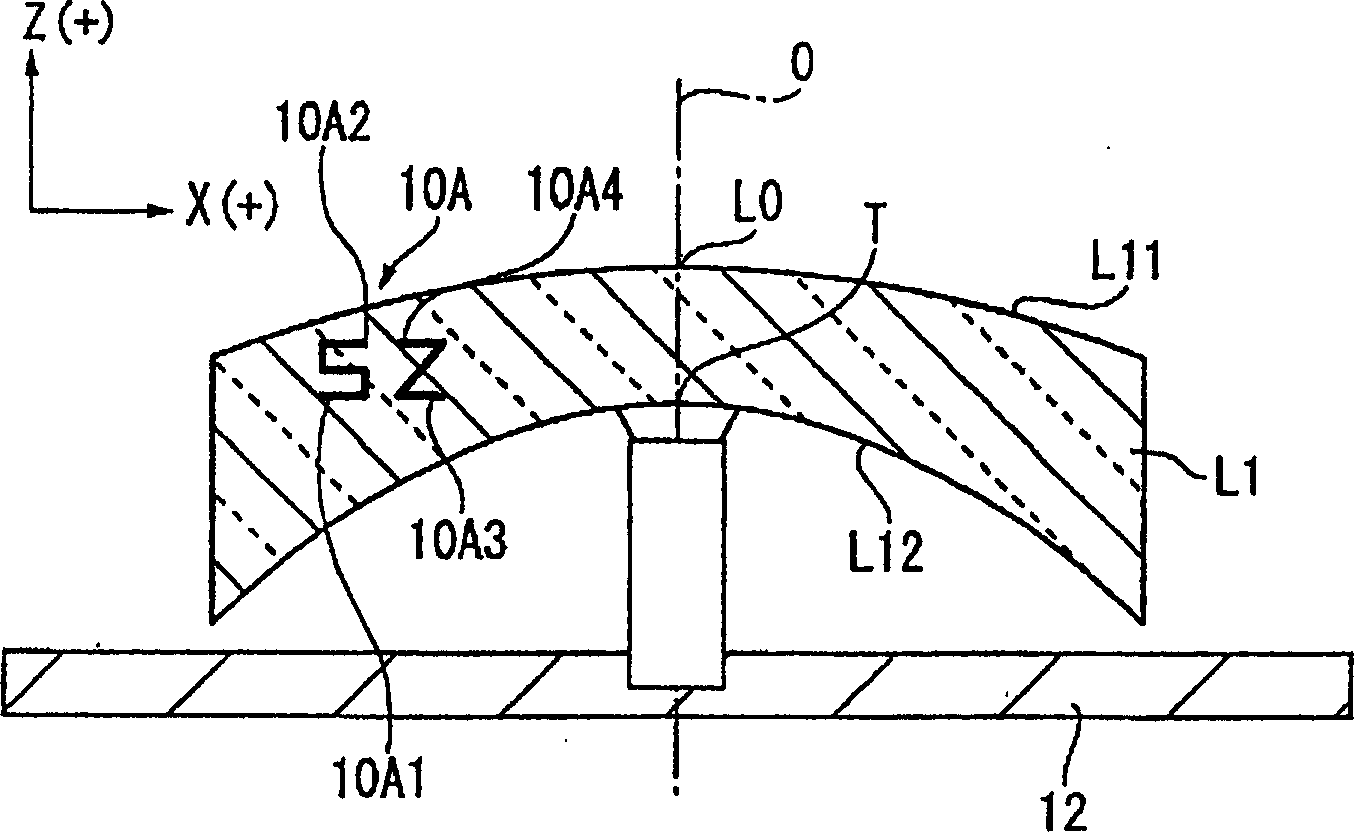

[0125] Below, refer to Figure 3 ~ Figure 11 A second embodiment of the present invention will be described. In the following description, the same reference numerals are attached to the same parts as those already described, and description thereof will be omitted.

[0126] image 3 A spectacle lens L2 having a mark 10B formed therein is shown.

[0127] The spectacle lens L2 of this embodiment is an inner progressive multifocal lens having a spherical or aspheric surface on the convex L11 side (outer side) and a progressive surface on the concave L12 side (inner side).

[0128] The spectacle lens L2 is made of the same material as the spectacle lens L1 of the aforementioned embodiment.

[0129] On the convex surface L11 and the concave surface L12 of the spectacle lens L2, although not shown in the figure, a hard coat film for improving scratch resistance and for preventing reflections such as glare and double images caused by reflection of light is formed. Prevent film e...

no. 3 approach

[0189] refer to Figure 12 to Figure 20 , the third embodiment of the present invention will be described.

[0190] Such as Figure 12 with Figure 13 As shown, the spectacle lens L3 of this embodiment is a spherical lens having a convex surface L11 with a curvature radius of 150 mm, a concave surface L12 with a curvature radius of 150 mm, and a center thickness of 3 mm.

[0191] In the present embodiment, the mark 10C formed inside the spectacle lens L3 is a character such as EP and has a planar structure. When the size of each character is viewed from the X-Y plane, one side W1 is a square of 1.0 mm, and the space W2 between each character is 0.5 mm. This mark 10C is formed at a position 15 mm away from the optical reference position L0 on the convex surface L11 side of the spectacle lens L3 in the X-axis direction ( Figure 12 in W3=15mm). Also, the mark 10C is formed approximately 0.5 mm below the surface of the convex surface L11 of the spectacle lens L3.

[0192] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com