Disposable syringe and transfusion system needle head and its production method

A technology of syringes and infusion sets, which is applied in the field of medical equipment, can solve problems such as human hazards, and achieve the effect of reducing injuries and reducing possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

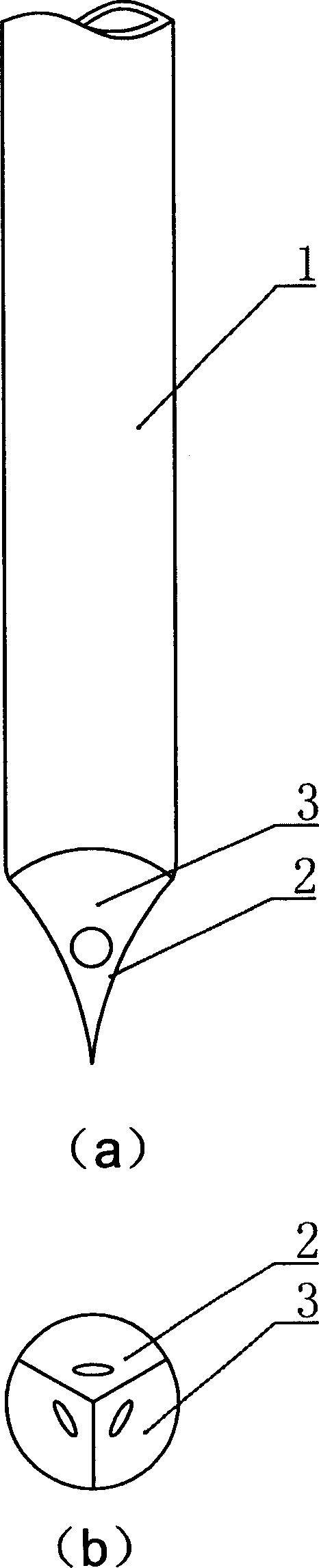

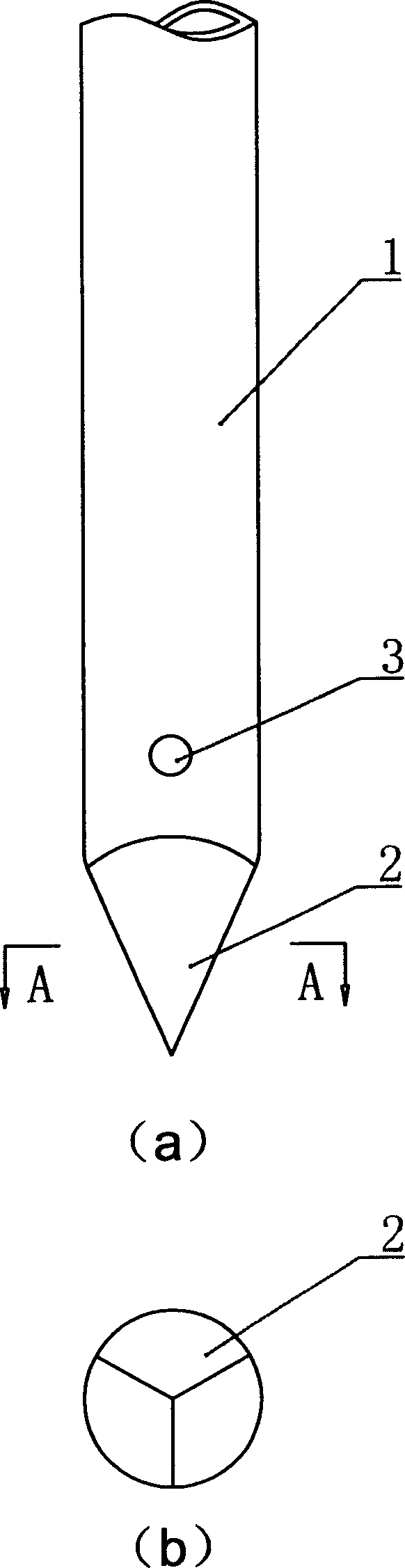

[0022] see figure 1 and figure 2 , the needle head at one end of the tubular needle body 1 of this embodiment is a triangular pyramid, and each cone surface 2 is slightly recessed in the axial direction and the circumference, and each cone surface 2 is provided with a liquid medicine through hole 3 near the tip. (Such as figure 1 shown), from figure 1 b It can be seen that the size of the liquid through hole 3 in the radial direction is very small. The liquid medicine through hole 3 can also be located at the position of the tubular needle body 1 near the needle (such as figure 2 shown).

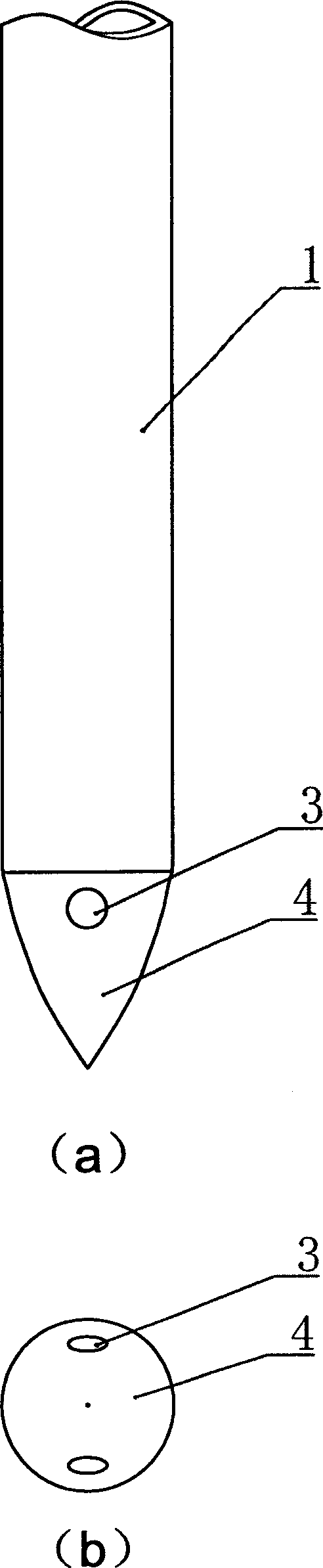

[0023] see image 3 and Figure 4 , the needle head at one end of the tubular needle body 1 of this embodiment is conical, and the conical surface 4 is convex, and two liquid medicine through holes 3 are provided on the conical surface 4 near the tubular needle body 1 (such as image 3 shown). The number of liquid medicine through holes 3 can be increased or decreased according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com