Touch control plate with finger print identifying function and its manufacturing method

A manufacturing method and technology of a touch panel, applied to instruments, computer parts, graphics reading, etc., can solve problems that cannot be effectively solved, solvent pollution, spherical interstitial particles of different sizes, etc., to achieve market competition, Improvement of industrial competitiveness and cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

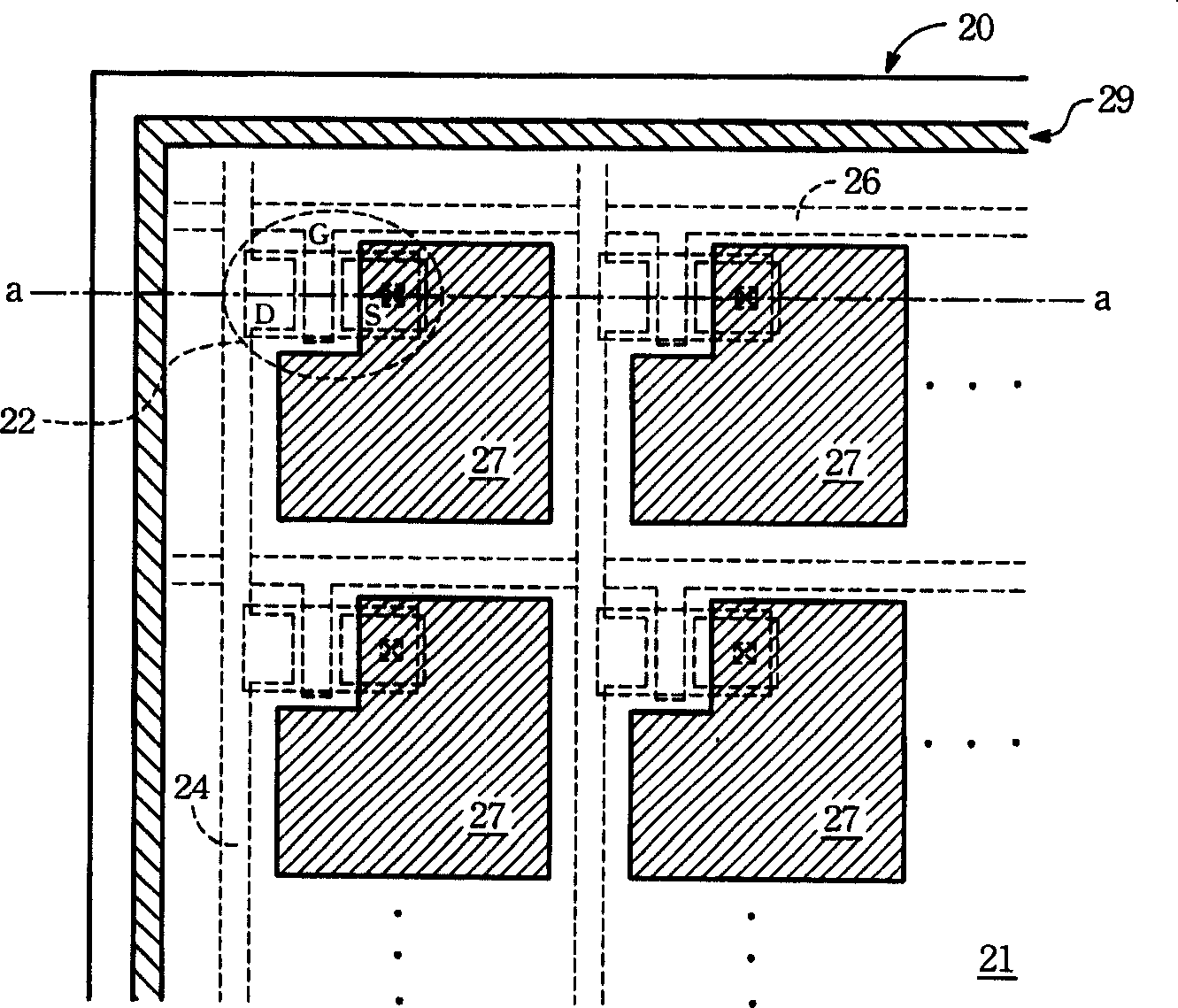

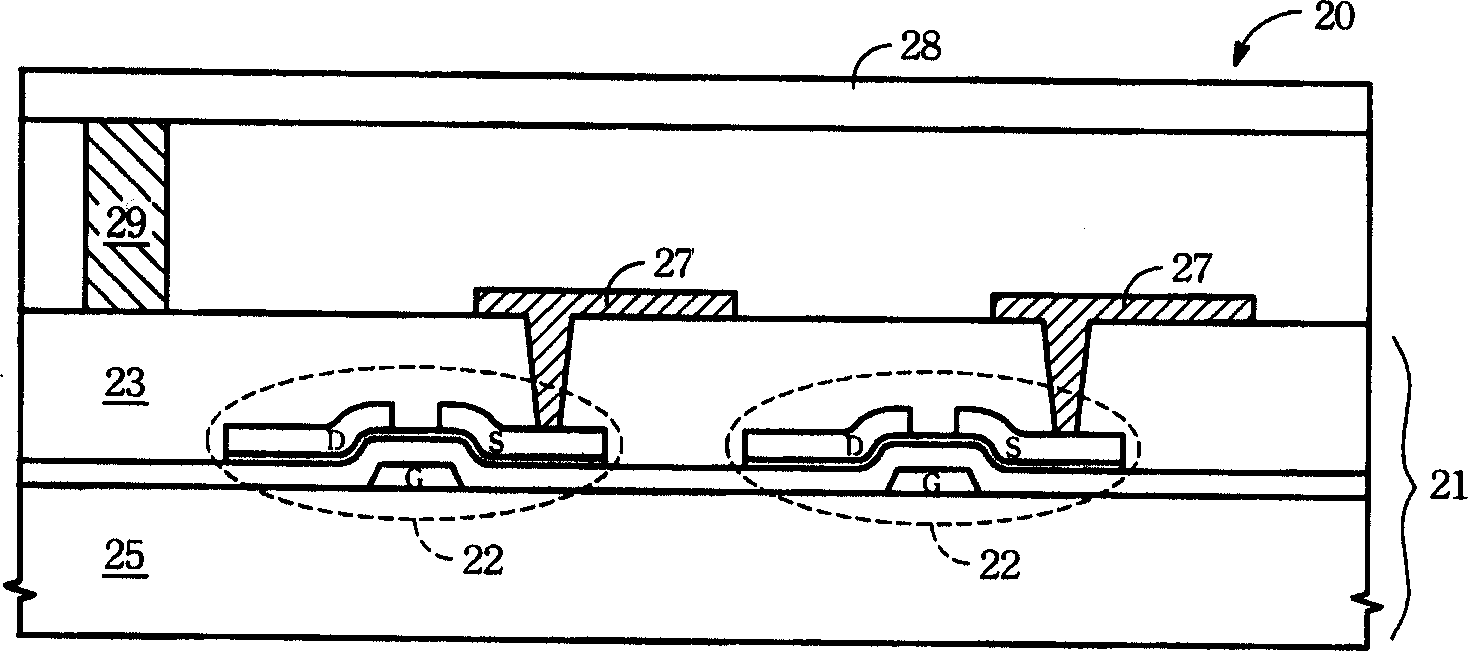

[0055] Please refer to Figure 3A , Figure 3B , which is a three-dimensional exploded view and a cross-sectional view of a part of the touch panel 40 with fingerprint recognition function of the present invention; Figure 3B is corresponding to Figure 3A The a-a section line in . Figure 3A Only a part of the touch panel 40 is shown, and only four thin film transistors 42 are shown as representatives. Although this embodiment uses the bottom gate thin film transistor 42 (Bottom Gate TFT) as a template, the top gate thin film transistor ( Top Gate TFT) can also be used. The touch panel 40 provided by the present invention can be applied to an electronic device, such as a tablet computer, a display panel or a screen, and the like. The touch panel 40 includes a transistor panel 41 , a plurality of conductive blocks 47 , a support pattern layer 52 and a conductive elastic film layer 48 .

[0056] The transistor board 41 includes a substrate 45 , thin film transistors 42 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com