Cold de-aeration in production of citrus juices

A technology of citrus juice and degasser, which is applied in food science and other fields, and can solve the problems of expensive and low efficiency of two-step operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

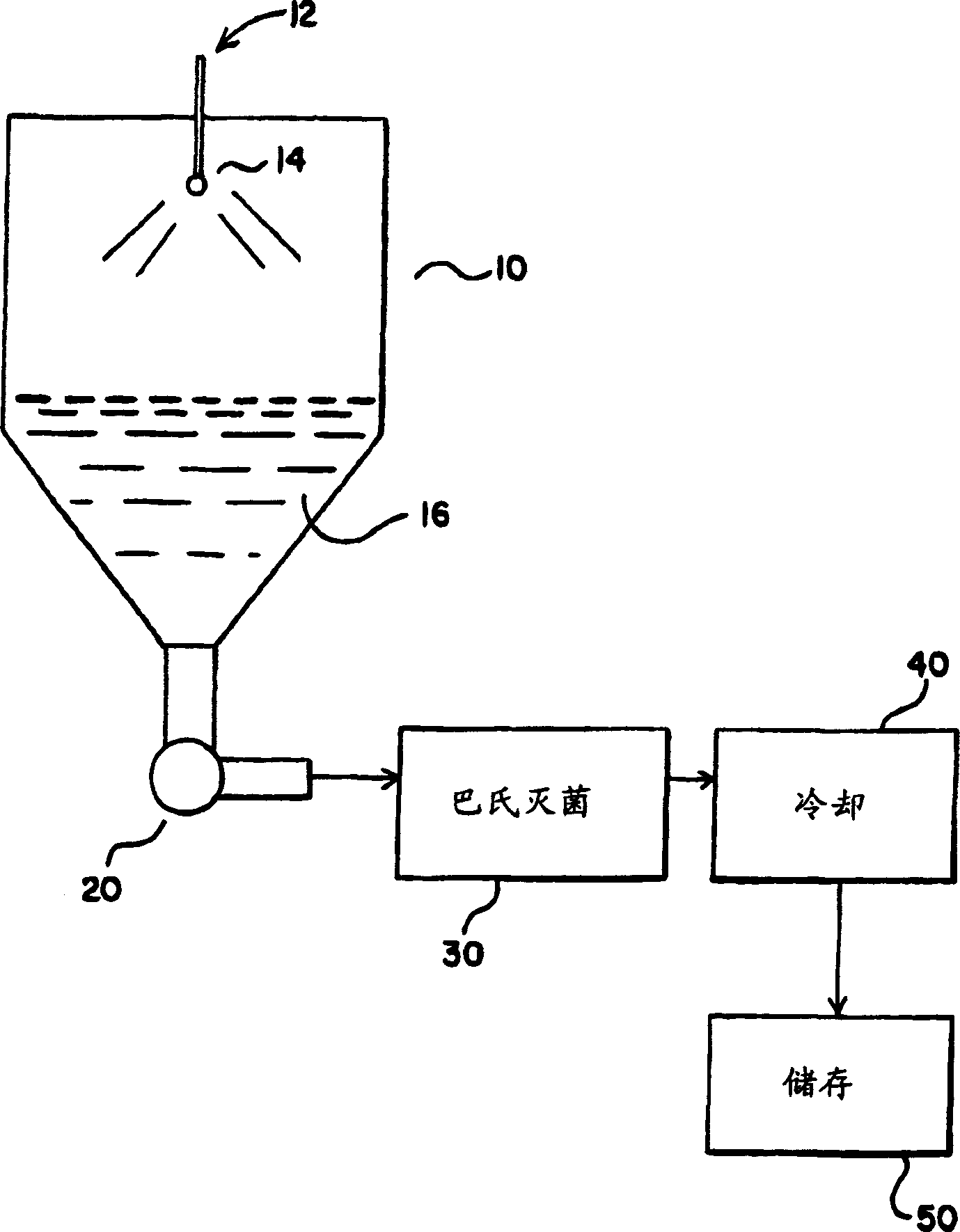

Method used

Image

Examples

Embodiment

[0020] An APV degasser tank modified with a WhirlJet(R) #3 nozzle was used in this example. Initially, the NFC orange juice was cooled to a temperature of 35°F. The cooled juice is then sent to the degasser tank. The tank was maintained under a vacuum of 28-30 inches Hg. The flow rate of juice into and out of the tank was 1.20 gallons per minute, resulting in a hold-up volume of 20 gallons remaining in the tank. This allows the juice to sit in the tank for approximately twenty (20) minutes before draining. The test was such that the dissolved oxygen content in the juice exiting the tank was an average of 0.545 ppm. This was slightly above the desired level, indicating that successful degassing was achieved under these conditions, which were relatively mild and did not harshly manipulate the organoleptic qualities of the juice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com