Liquid-liquid extraction method

An extraction and extraction agent technology, applied in the field of liquid-liquid extraction, can solve problems such as difficult implementation and no extraction device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

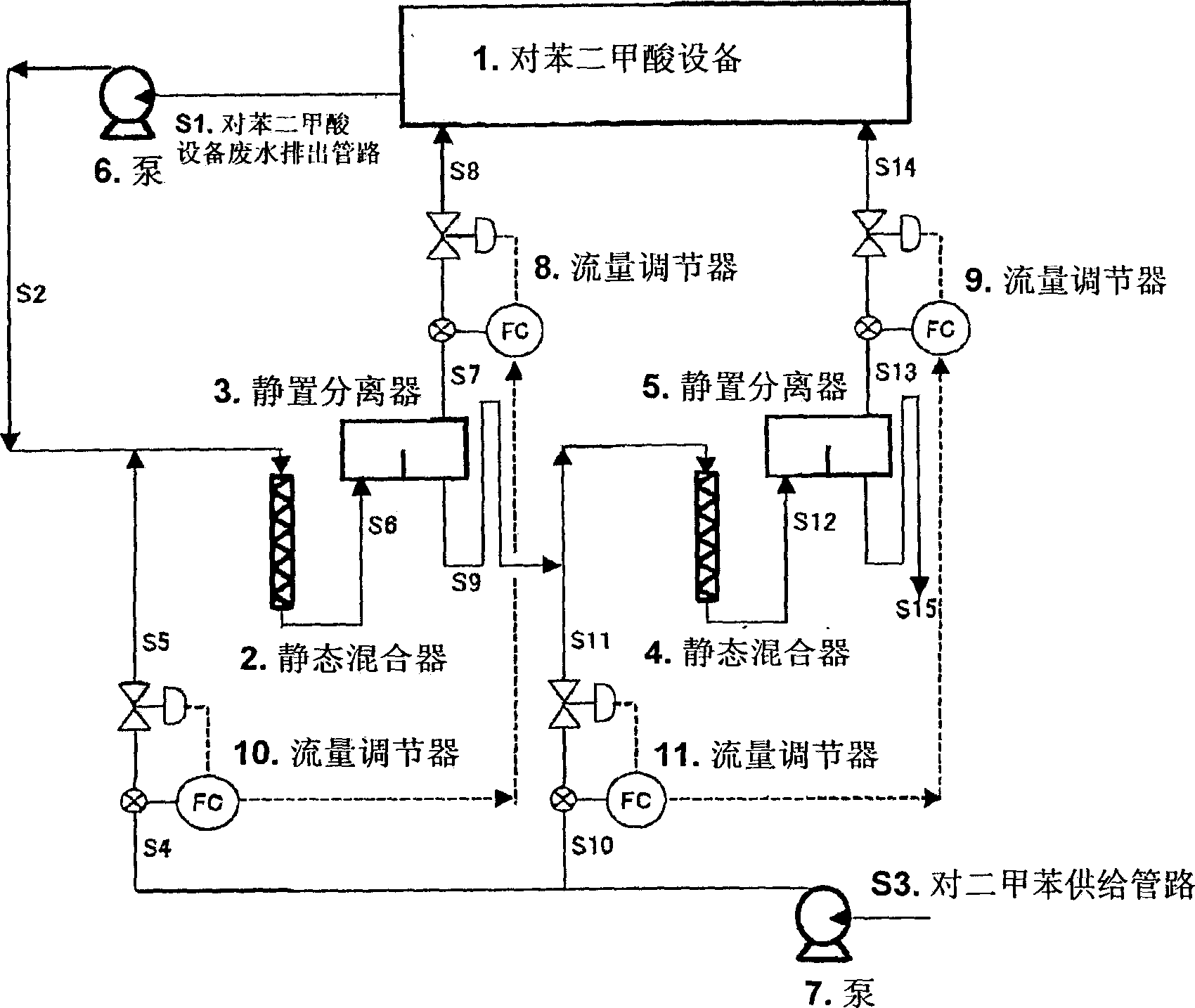

[0058] figure 1 A schematic diagram illustrating an embodiment of the present invention. The waste water from the terephthalic acid plant 1 flows through the waste water discharge line S1, the pressure is raised to 0.6 MPa-G by the pump 6, and mixed with the p-xylene from the supply line S5 at the static mixer 2. The p-xylene from the supply pipeline S5 is to flow through the supply pipeline S3, use the pump 7 to raise the pressure to 0.7MPa-G, and use the flow regulator 10 to adjust the flow rate to be 4 parts by weight of waste water: 1 part by weight of p-xylene . The static mixer 2 is a product of NORITAKE, the number of elements for changing the flow direction is 12, and the stagnation time is 15 seconds.

[0059] The liquid mixed by the static mixer 2 flows through the supply line S6 and is supplied from the lower part of the static separator 3 . The p-xylene after liquid-liquid separation flows through the outlet pipeline S7, and the flow rate is adjusted by the flow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap