Production and apparatus of light strips in filling formation building

A technology of filling molding and production methods, applied in the field of construction, can solve the problems of poor fluidity of slurry and no material in the mold cavity, and achieve the effect of convenient filling and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

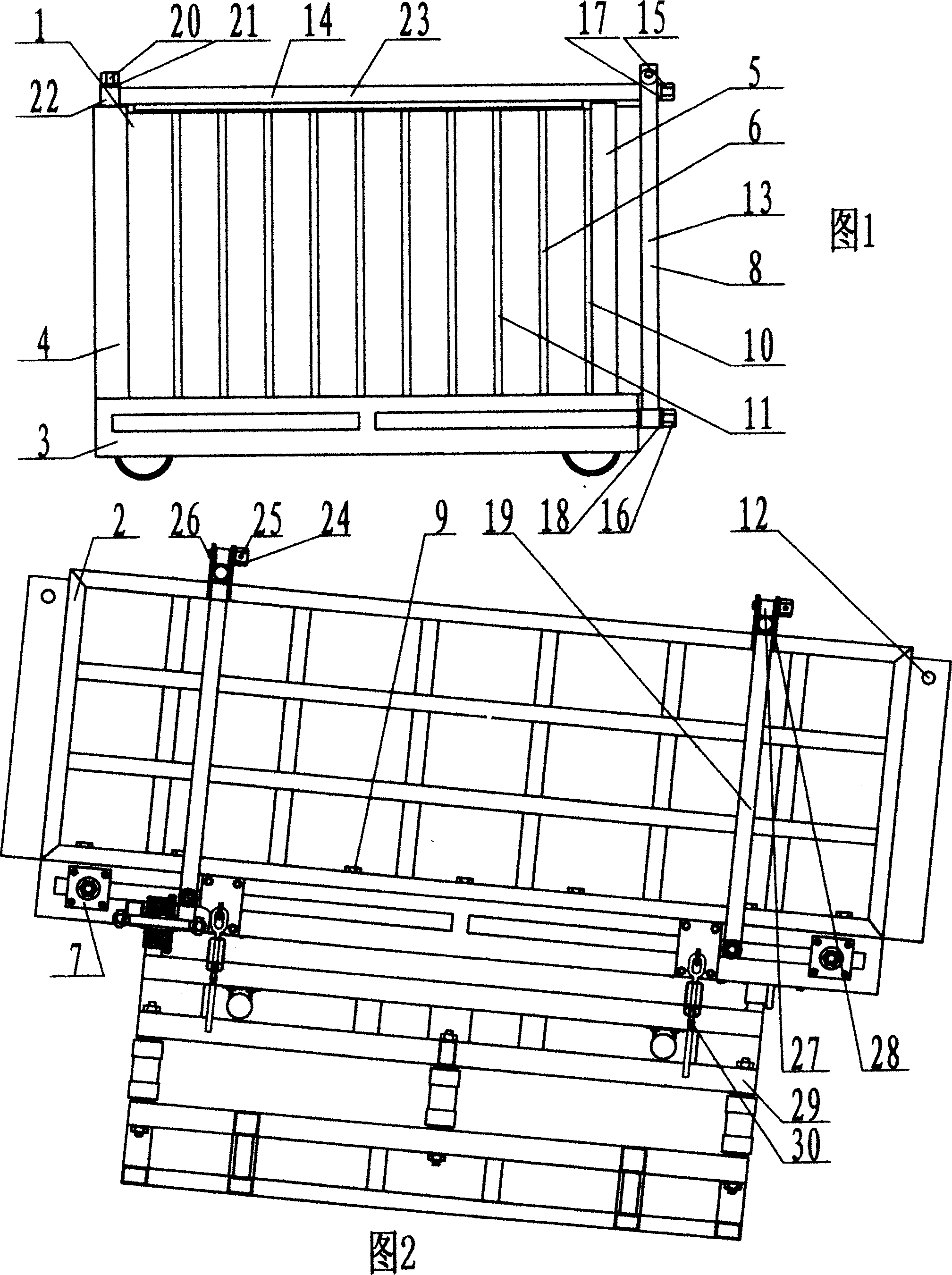

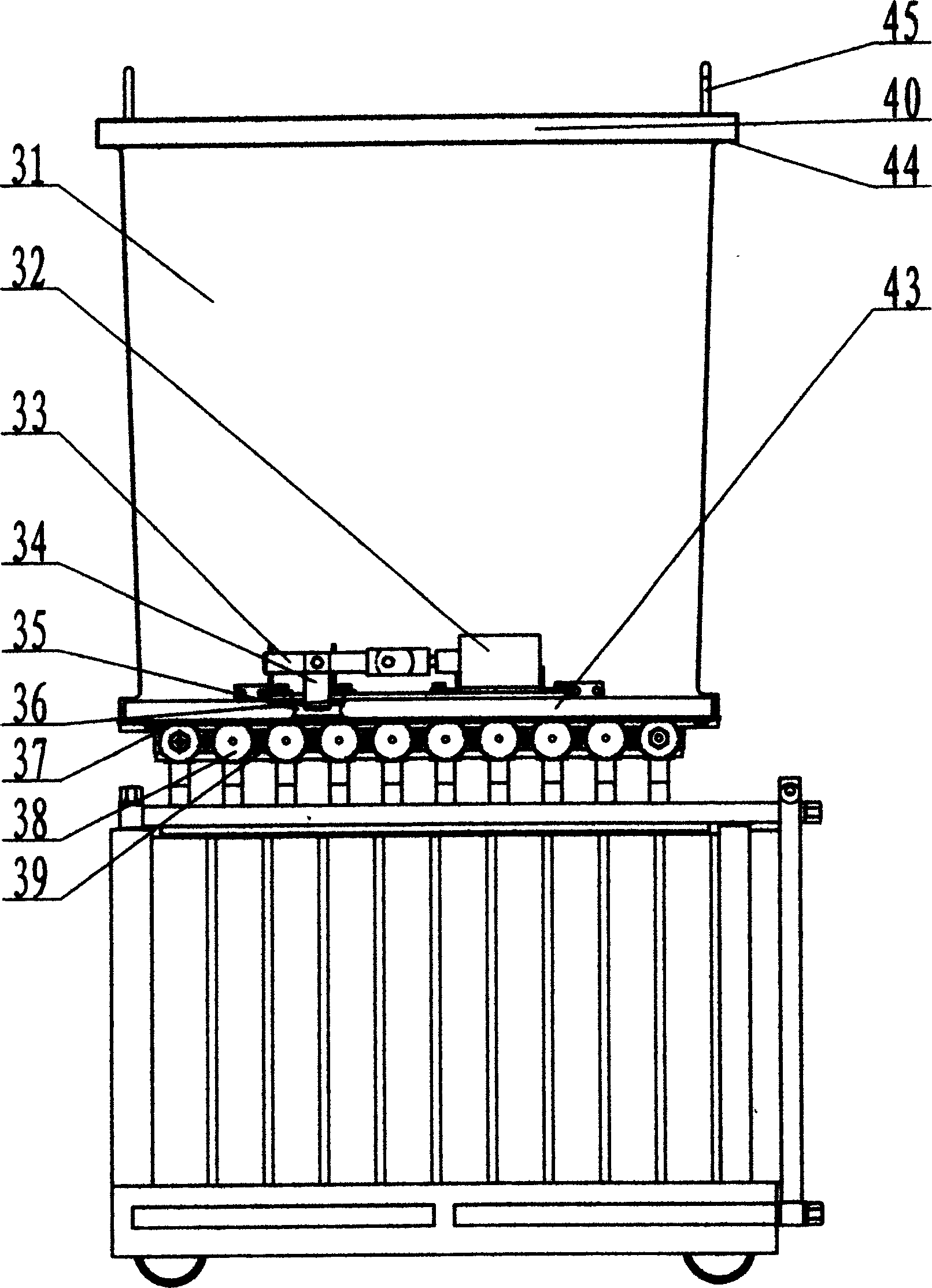

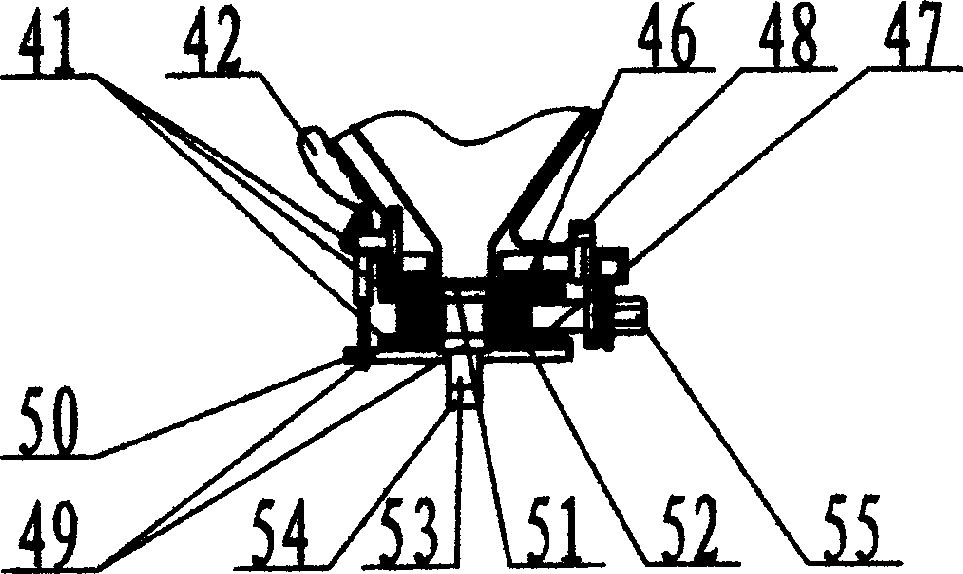

[0034]The forming mold 1 is placed on the mold carrier 2, and the mold carrier is composed of an underframe 3, a fixed fence 4, a movable fence 5, a forming partition 6, a parting mechanism 7, and a clamping mechanism 8, The fixed fence 4 is connected with the underframe 3 of the formwork vehicle through bolts 9. The fixed fence 4 is welded into a fence by square tubes for strength reinforcement. The side of the fixed fence 4 in contact with the forming mold 1 is inlaid with a fixed partition 10, which can also be divided into two parts. body state. Stand the forming mold 1 sideways on the mold carrier 2, make it close to the fixed partition 10, and then stand sideways on a movable partition 11. The movable partition is made of plastic material, or any other material. Such as wood, bamboo, aluminum alloy, steel plate, enamel, etc., the two sides of the movable partition 11 are all formed with texture, and there are hoisting holes 12 on both sides of the upper end. Repeat the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap