Reinforcing-bar concrete building roof with tree-dimensional bearing structure

A reinforced concrete, three-dimensional technology, applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of not considering formwork design, unable to resist up and down pull force and horizontal shear force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

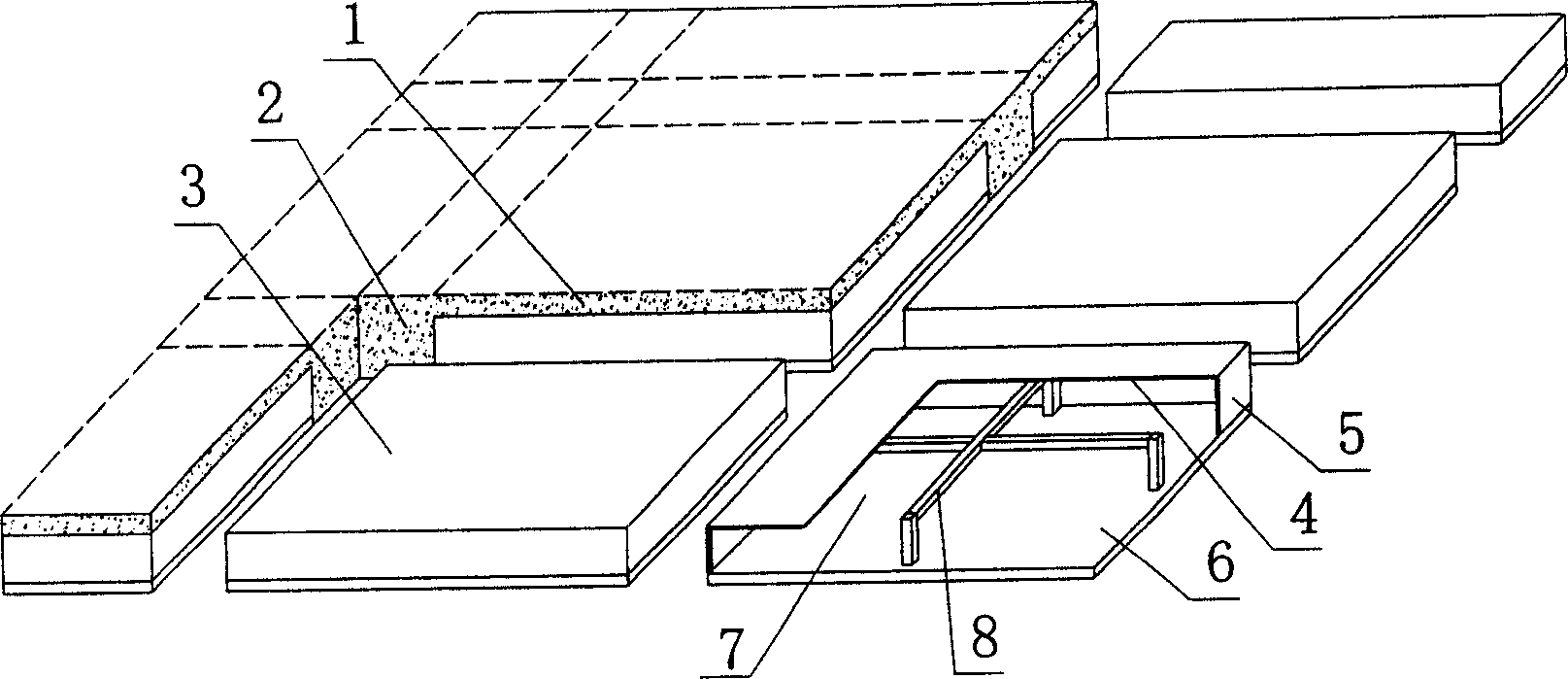

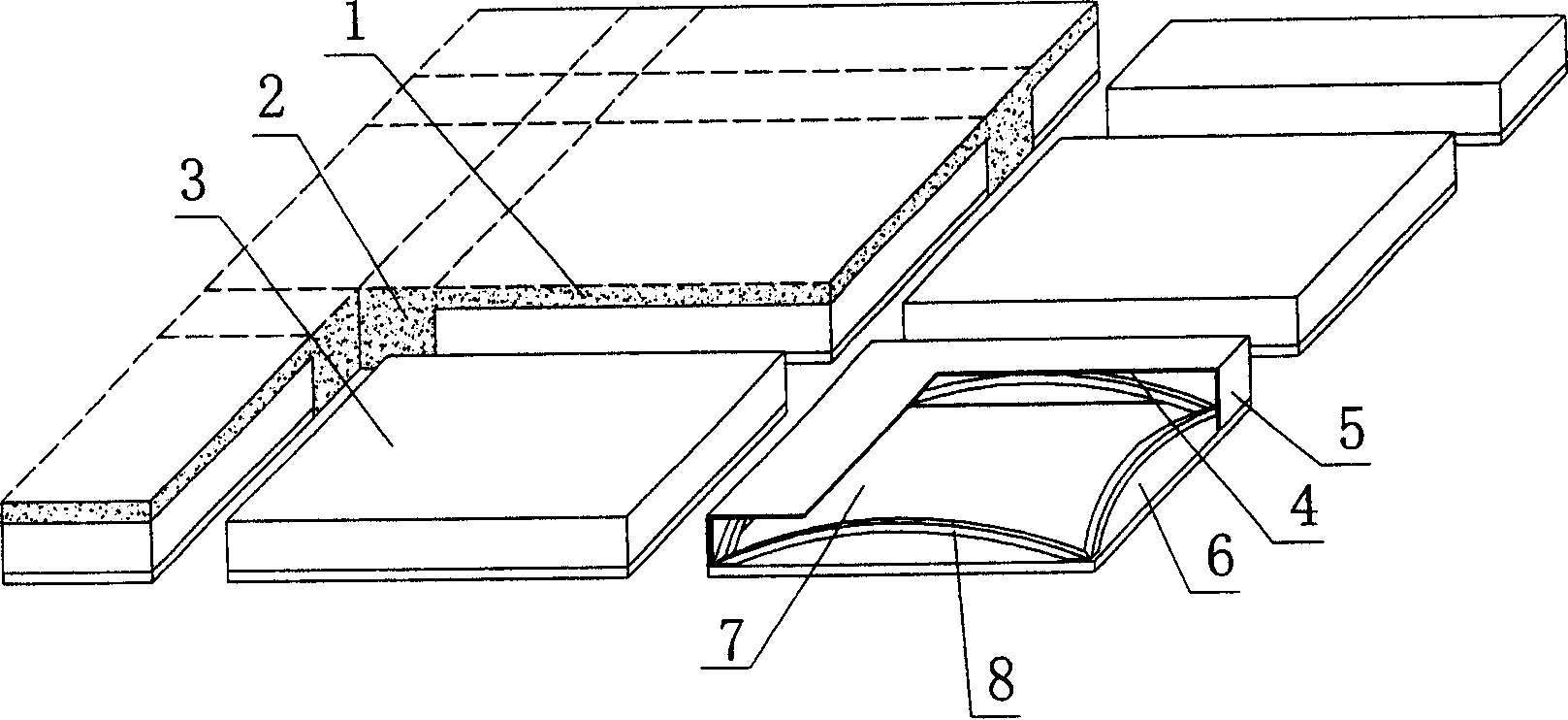

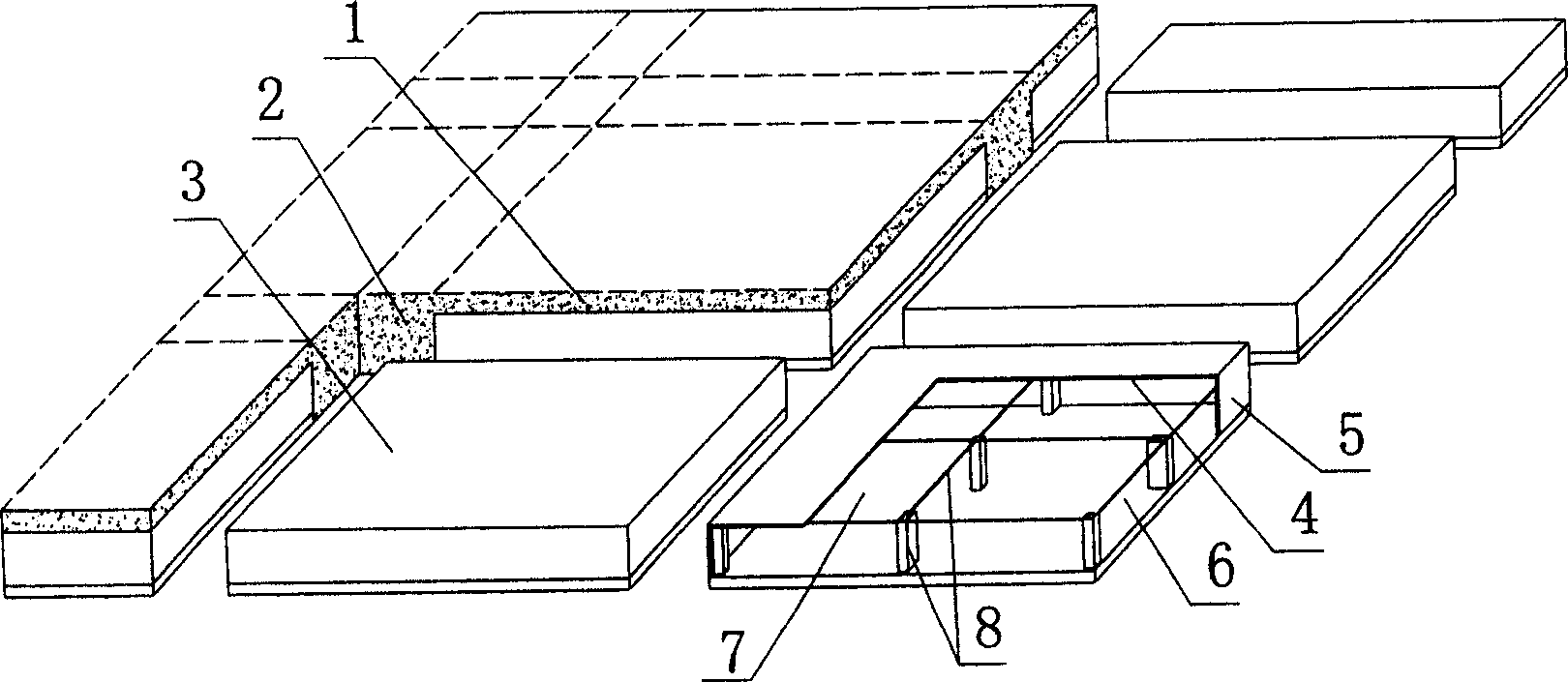

[0074] As shown in the accompanying drawings, the present invention comprises a cast-in-place reinforced concrete upper plate 1, a cast-in-situ reinforced concrete rib 2, a cavity formwork 3, and the cavity formwork 3 is arranged at intervals, in which there are cast-in-situ reinforced concrete ribs 2, on which are The cast-in-place reinforced concrete upper plate 1, the three are poured into a whole, wherein the cavity formwork 3 includes the upper roof 4, the surrounding side walls 5 and the lower bottom 6, and the upper roof 4, the surrounding side walls 5 and the lower bottom 6 are connected to each other to form a polyhedron The cavity 7 is closed, the upper top plate 4 and the surrounding side walls 5 are superimposed with the cast-in-place reinforced concrete upper plate 1 and the cast-in-place reinforced concrete rib 2 respectively, and there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com