Scroll compressor

A scroll compressor and scroll technology, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve problems such as increased contact surface pressure, adhesion, compressor compression efficiency, and reduced durability. Achieve the effect of eliminating adhesion, high reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

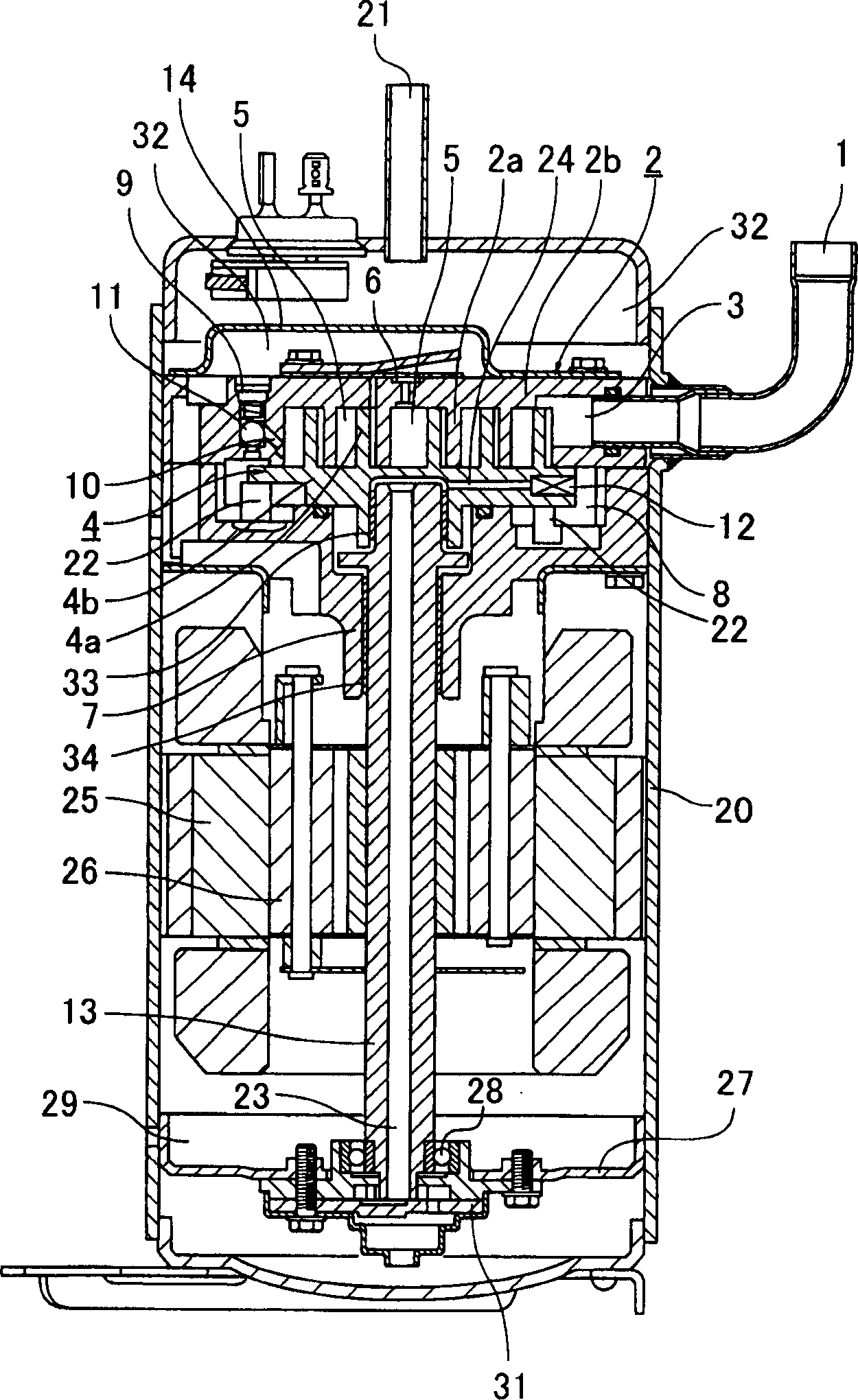

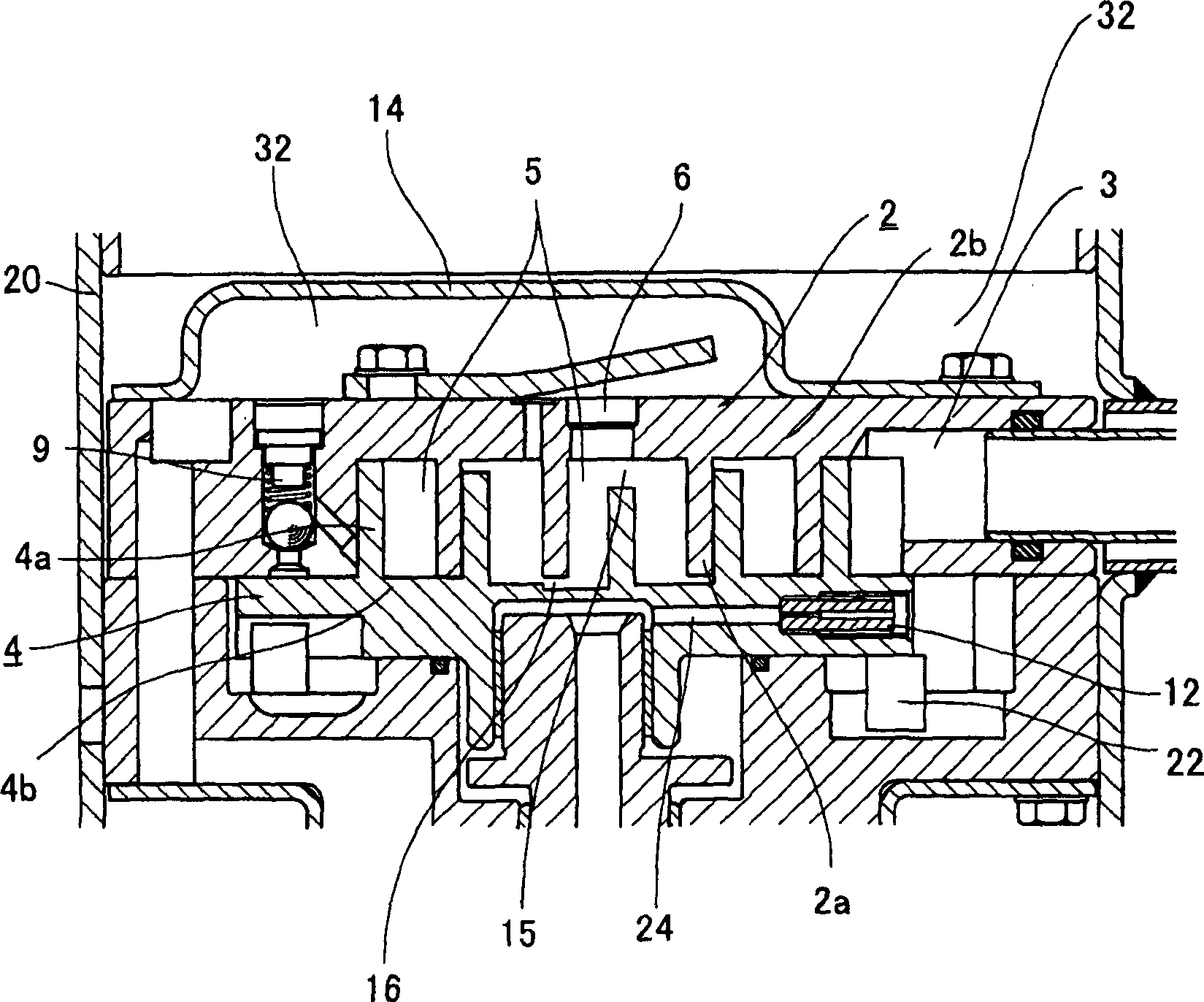

[0090] figure 1 It is a longitudinal sectional view showing the scroll compressor according to the first embodiment of the present invention. In addition, in the scroll compressor of the first embodiment shown in the figure, for Figure 17 In the illustrated conventional scroll compressors, the same functions are denoted by the same reference numerals.

[0091] The scroll compressor of this embodiment has a compression mechanism part and a motor mechanism part in the hermetic container 20 . The compression mechanism part is arranged above the airtight container 20, and the motor mechanism part is arranged below the compression mechanism part. In the upper part of the airtight container 20, a suction pipe 1 and a discharge pipe 21 are provided. In the lower part of the airtight container 20, there is an oil storage container 29 for storing lubricating oil.

[0092] The compression mechanism part is composed of a fixed scroll member 2 and an orbiting scroll member 4 , and th...

Embodiment 2

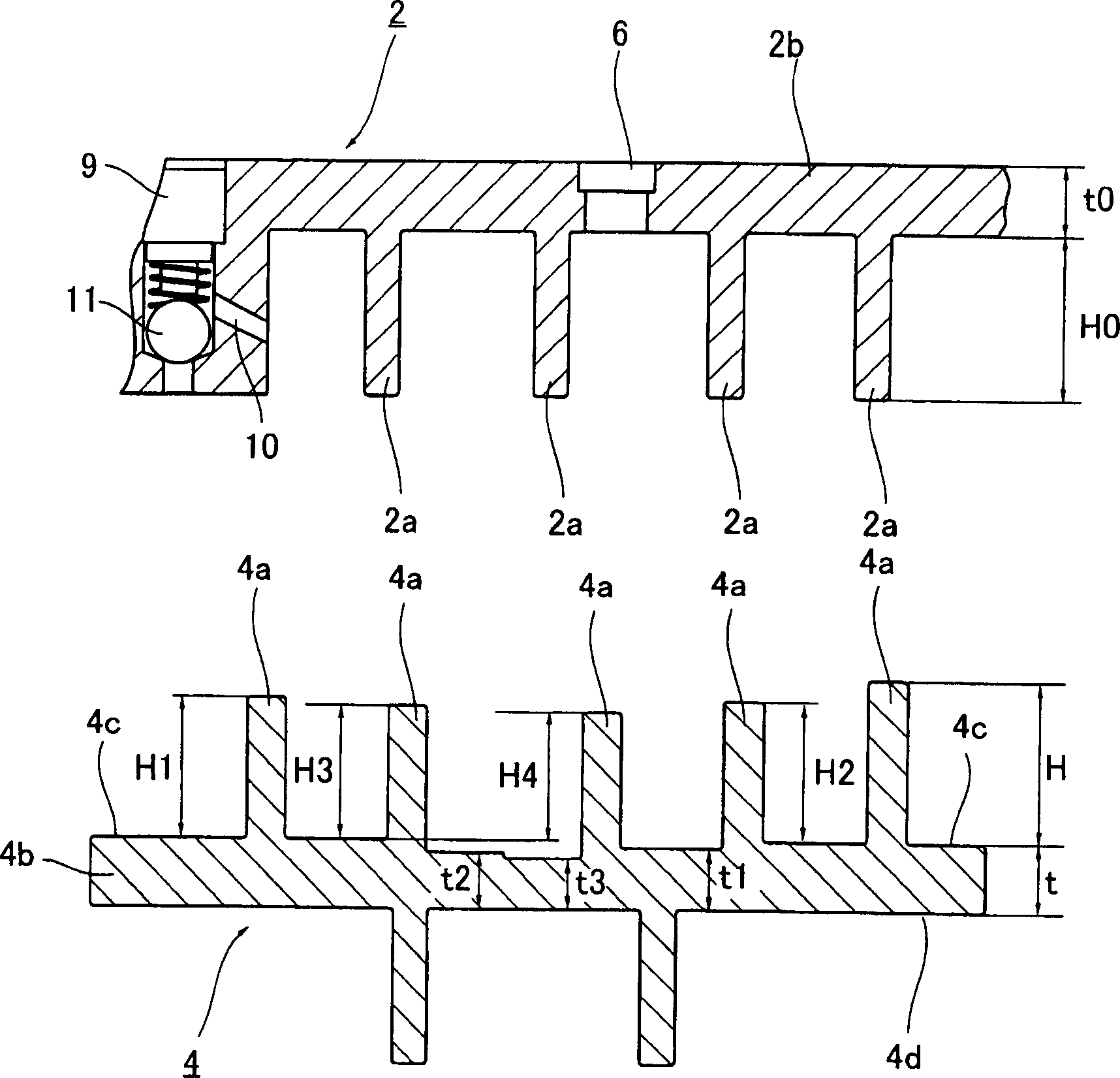

[0111] Next, a scroll compressor according to a second embodiment of the present invention will be described. Compared with the configuration of the first embodiment, the scroll compressor of the second embodiment is different in that the height of the wrap portion of the orbiting scroll member and the mirror plate are set so that carbon dioxide can be used as a refrigerant. The configuration of the thickness is different, and since the other configurations are the same as those of the first embodiment, they will be described using the drawings of the first embodiment.

[0112] That is, when carbon dioxide is used as the refrigerant, the operating pressure of the compressor is very high compared with the case of using conventional freon refrigerants. Even in stable operation, the discharge pressure rises to about 10 MPa, and the suction pressure rises to 4MPa level. At this time, a large pressure difference is generated between the compression chamber 5 side and the back pres...

Embodiment 3

[0120] Next, a scroll compressor according to a third embodiment of the present invention will be described. Figure 4 is a longitudinal sectional view showing a scroll compressor according to a third embodiment of the present invention, Figure 5 yes Figure 4 The sectional view of the main part of the compression mechanism part of the scroll compressor shown, Image 6 yes Figure 4 A top view of the orbiting scroll component of the scroll compressor shown, Figure 7 yes Figure 4 A side sectional view of an orbiting scroll member of a scroll compressor shown, Figure 8 yes means Figure 4 A graph of the height ratio of the orbiting wrap portion of the orbiting scroll member of the scroll compressor shown. Additionally, for Figure 17 In the conventional scroll compressor shown, the same functional components are denoted by the same symbols, and the same applies to the fourth to tenth embodiments described below.

[0121] The scroll compressor of this embodiment has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com