Thin film transistor array panel

A thin-film transistor and array panel technology, applied in the field of thin-film transistor array panels, can solve problems such as reducing the aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

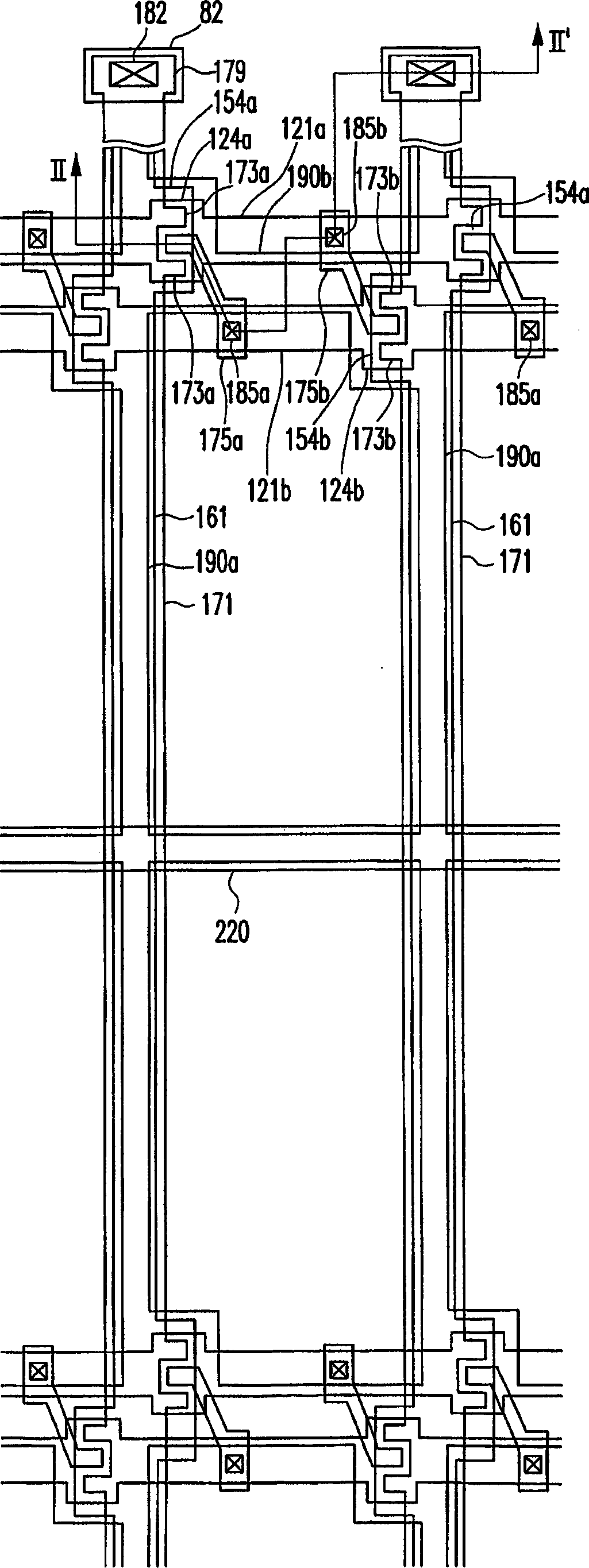

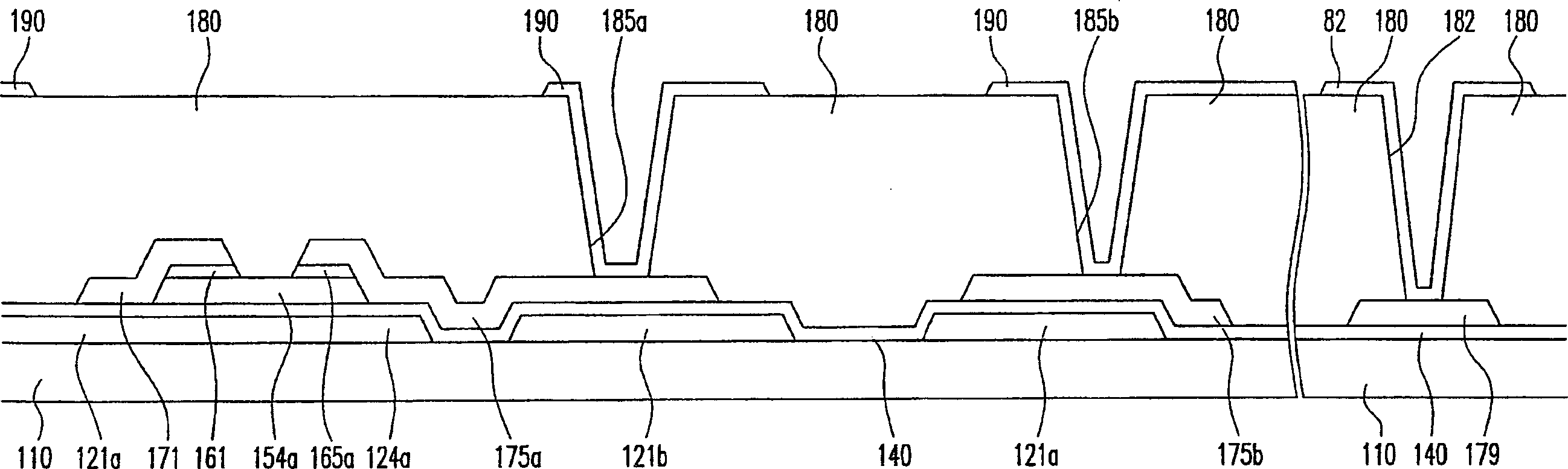

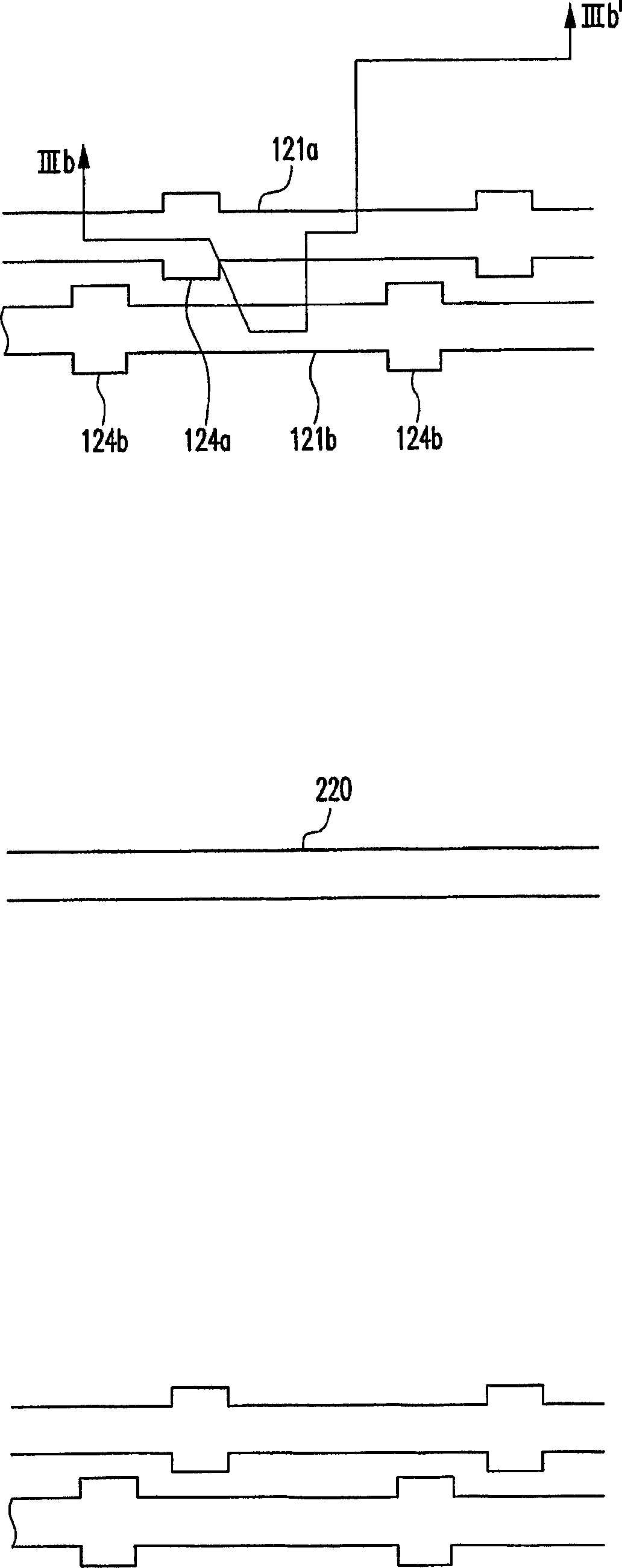

[0076] Unlike the above-described embodiments, the color filters are formed on the TFT array panel of the LCD. Such as Figure 11 with Figure 12 As shown, the TFT array panel according to another embodiment of the present invention has a layered structure, and the layered structure is the same as figure 1 with figure 2 The examples shown in are equivalent.

[0077] Figure 11 is a layout diagram of a TFT array panel of an LCD according to another embodiment of the present invention, Figure 12 was taken along line XII-XII' Figure 11 The cross-sectional view of the TFT array panel shown in .

[0078] and figure 1 with figure 2 Unlike the TFT array panel in , the color filters 230R, 230G, and 230B are formed on the passivation layer 180p. The passivation layer 180p is made of an insulator such as silicon oxide or silicon nitride, and the passivation layer 180p protects the exposed portion of the semiconductor 154 and prevents a color agent from the color filter to a...

no. 3 example

[0092] Different thin films other than the color filter on the TFT array panel according to the above-described embodiments are formed of a photoresist film, and the formation of the different thin films will be described in detail with reference to the accompanying drawings.

[0093] Figure 17 is a layout diagram of a TFT array panel of an LCD according to another embodiment of the present invention, Figure 18 was taken along line XII-XII' Figure 17 The cross-sectional view of the TFT array panel shown in . Figure 19 In the middle step of the manufacturing method of the TFT array panel according to the embodiment of the present invention Figure 17 with Figure 18 A cross-sectional view of the TFT array panel shown in, Figure 20 is in Figure 19 The cross-sectional view in the next step of the steps shown in, Figure 21 is in Figure 20 In the layout diagram shown in the next step of the steps, Figure 22 is taken along the line XVb-XVb' Figure 21 A cross-secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com