Semiconductor device and its manufacturing method

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as inability to meet requirements, and achieve the effect of high withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

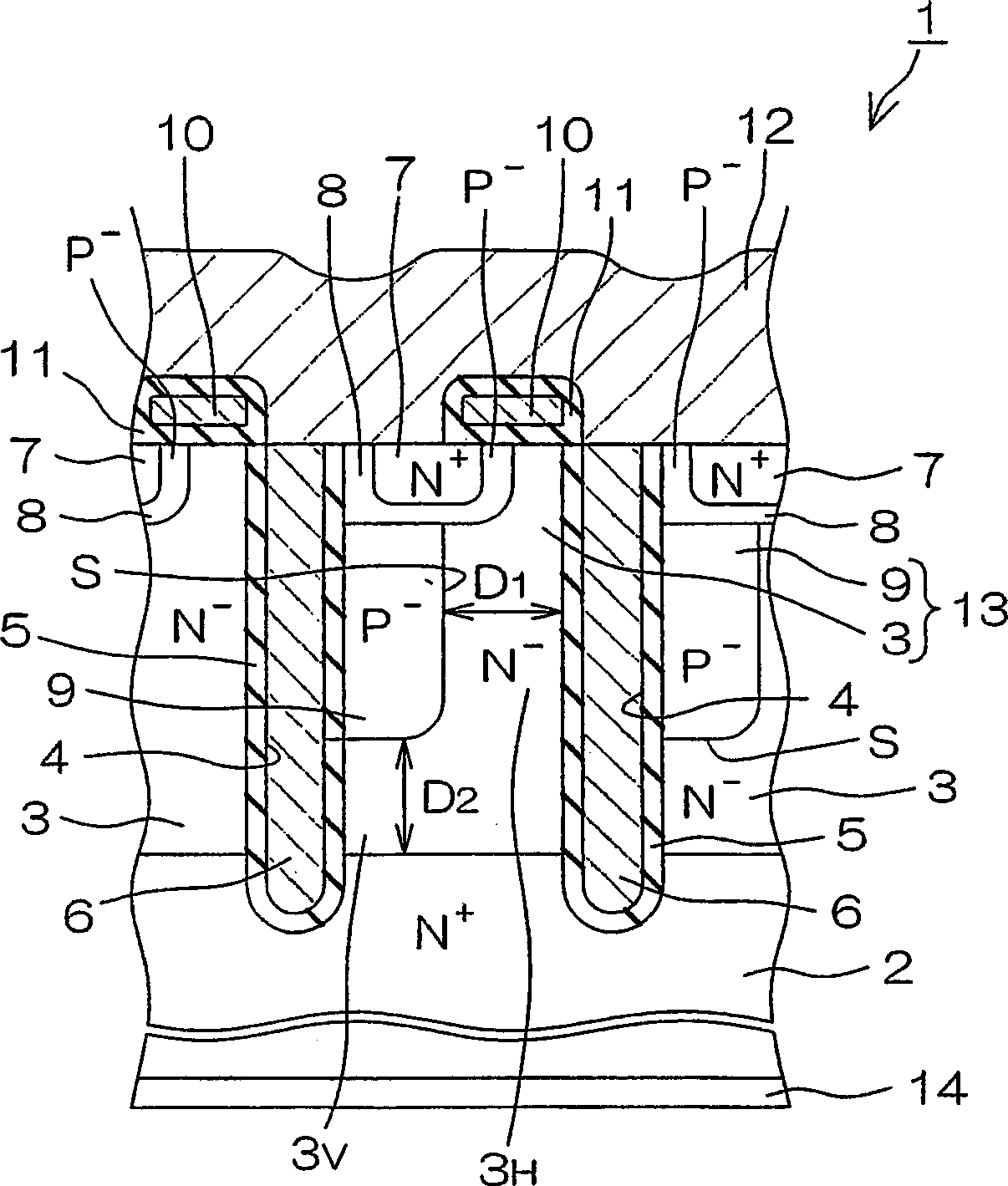

[0047] figure 1 It is a schematic cross-sectional view showing the structure of the semiconductor device 1 according to the first embodiment of the present invention.

[0048] In the constituent conductivity type is N + On the silicon substrate 2 constituting the drain region, a semiconductor layer 13 forming a so-called super junction structure is provided. The semiconductor layer 13 includes conductivity type N - type of the drift layer 3 and the conductivity type is P - type RESURF layer 9, the drift layer 3 and the RESURF layer 9 are arranged so that they appear alternately (repeatedly) in sequence on the silicon substrate 2 in parallel and laterally.

[0049] A plurality of trenches 4 penetrating the semiconductor layer 13 to a depth of the silicon substrate 2 are formed substantially parallel to each other. The trench 4 has an inner side wall that is substantially perpendicular to the silicon substrate 2, and is perpendicular to the figure 1 Extend in the directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com