Press mold and method of manufacturing optical element

A technology of molding and manufacturing methods, which is applied in manufacturing tools, glass pressing, glass manufacturing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, best embodiments of the press-molding mold and the method of manufacturing an optical element of the present invention will be described with reference to the drawings.

[0056] 〔Compression forming die〕

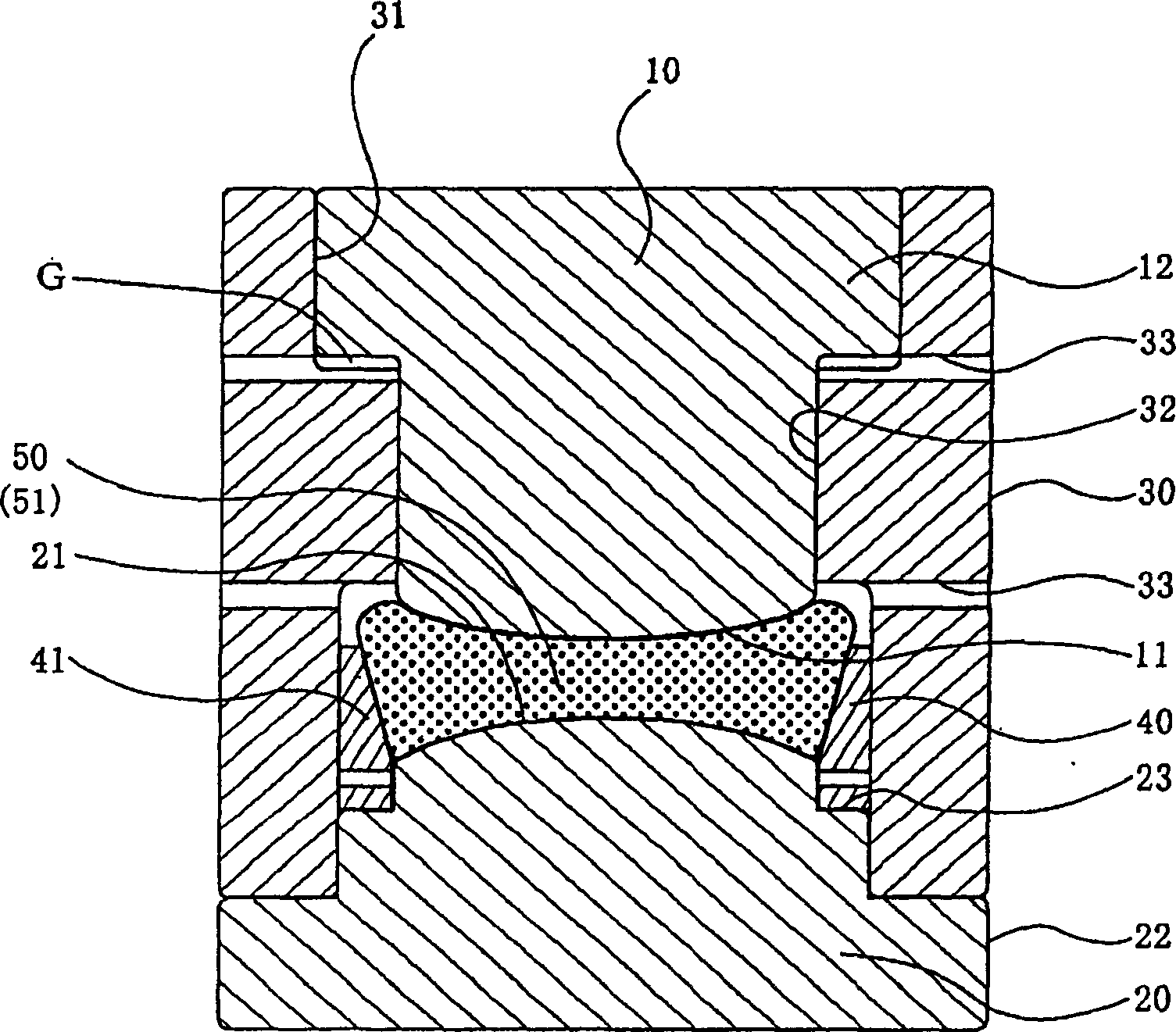

[0057] First, refer to figure 1 , an embodiment of the press forming die (hereinafter, simply referred to as forming die) of the present invention will be described. figure 1 is a schematic cross-sectional view of the molding die of this embodiment, showing the state when a press load is applied (refer to Figure 4D (8)).

[0058] figure 1 The shown forming die includes an upper die 10 , a lower die 20 , a drum die 30 , and a support member 40 , and press-forms a forming material 50 between the upper die 10 and the lower die 20 .

[0059] In this embodiment, the drum mold 30 limits their relative positions in the horizontal direction by sliding and guiding the upper and lower molds 10, 20 when assembling the forming mold and when stamping and forming,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com