Side plate structure in refrigerator body and refrigerator with same

A technology of plate structure and box body, applied in the field of refrigerated box structure, can solve the problems of complicated welding process of pre-coated aluminum plate and patterned aluminum plate, long procurement cycle of pre-coated aluminum plate and patterned aluminum plate, weak rigidity of inner plate, etc. Low cost, enhanced strength and stiffness, enhanced crashworthiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

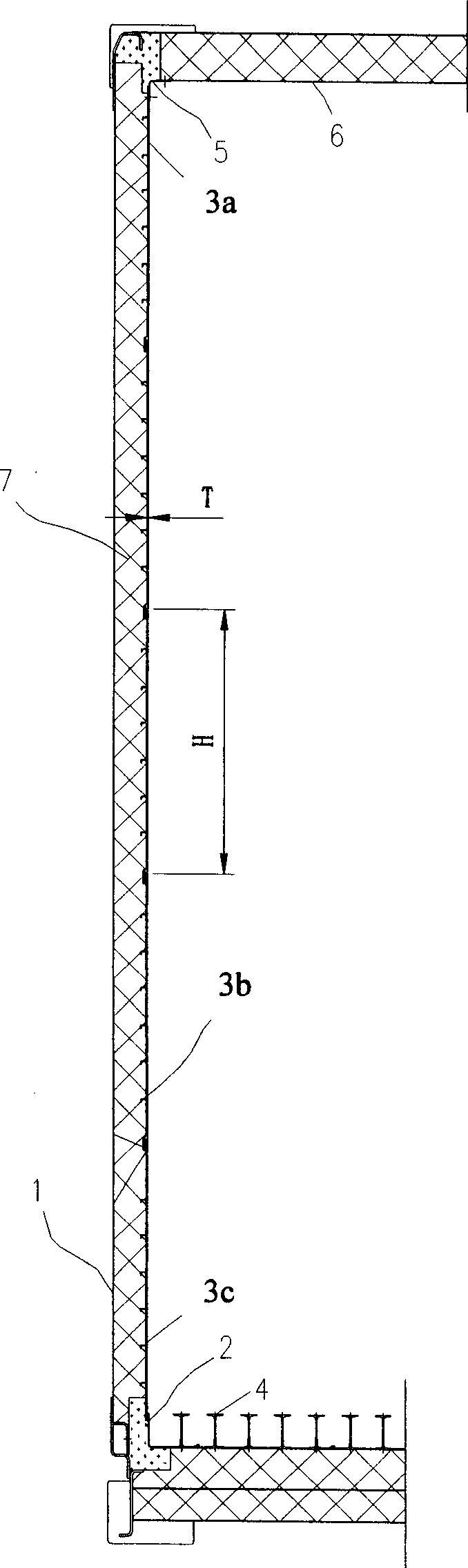

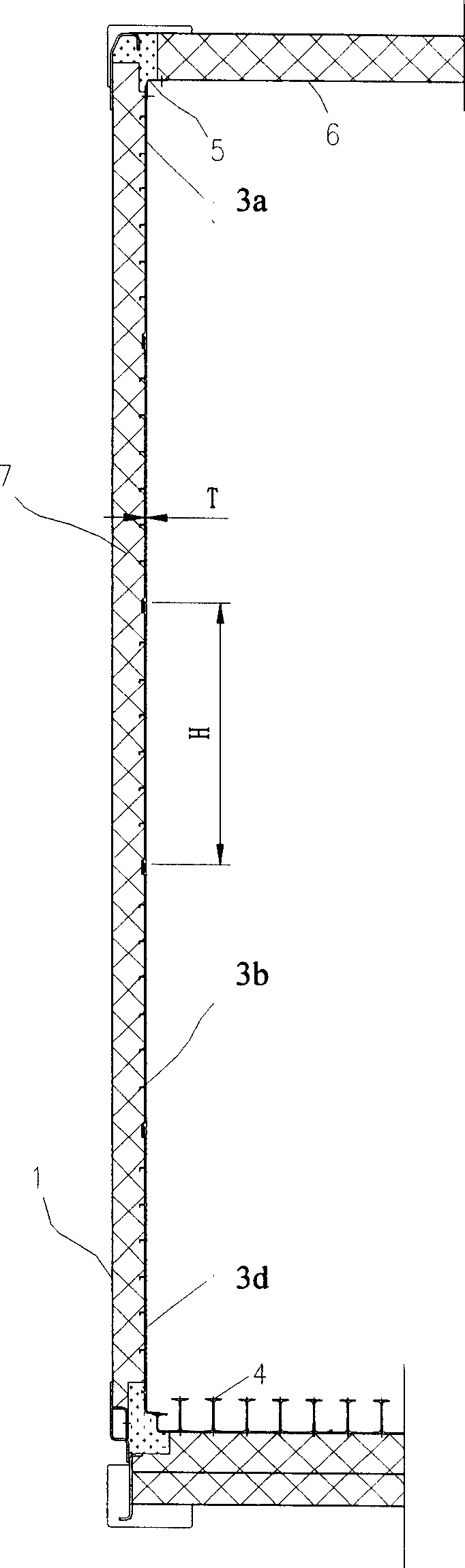

[0032] Such as figure 1 Shown is the first embodiment of the refrigerated / refrigerated box applying the aluminum profile inner panel structure of the present invention, and this refrigerated / refrigerated box can be used in containers or transport vehicles.

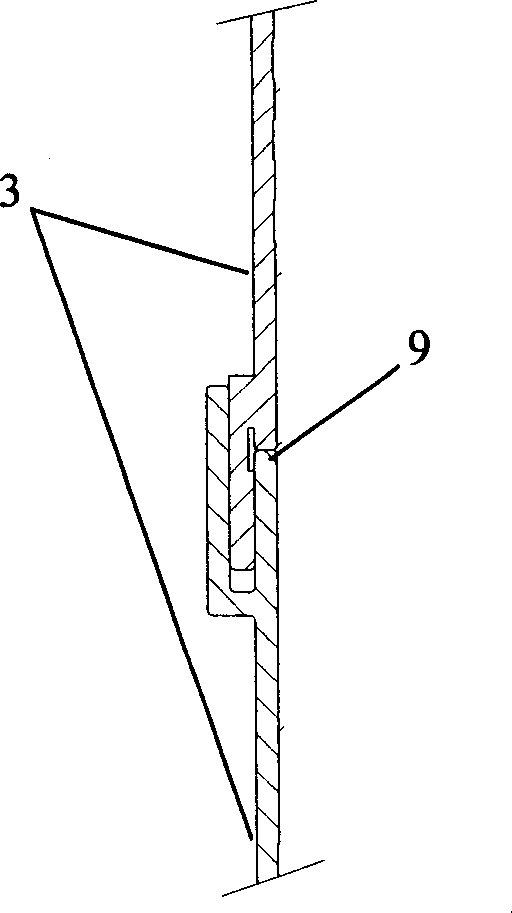

[0033] figure 1 Among them, the box body includes an outer layer structure 1, an inner layer structure 8 and an insulation layer 7 between the inner and outer layer structures, and the inner layer structure 8 includes an inner panel 3, an aluminum floor 4, a top panel 6, an upper connecting piece 5 and a bottom connecting piece 2. The inner panel 3 is welded with the bottom connector 2 at the lower part, and the bottom connector 2 is welded or glued together with the aluminum floor 4; the inner panel 3 is welded, riveted or glued with the upper connector 5 at the upper part, and the upper connector 5 is again It is welded, riveted or glued together with the top plate 6 .

[0034] The inner panel 3 is made of tailor-weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com