Temp control electric heating cable and producing method

A heating cable and metal conductive wire technology, applied in the field of cables, can solve the problems of large starting current, low heating temperature, unstable performance, etc., and achieve the effects of small starting current, fast heating and starting, and high quality stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

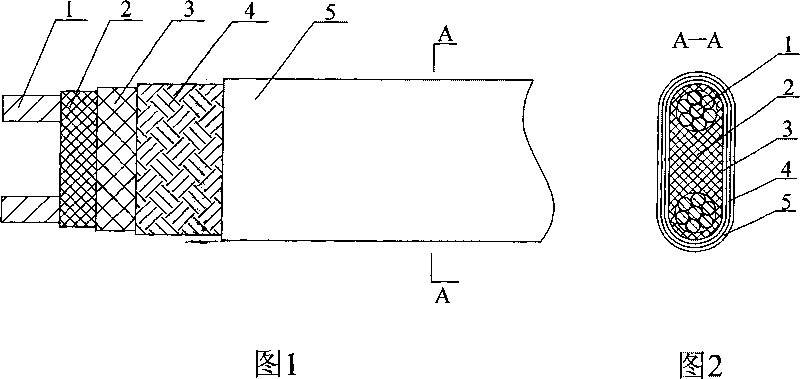

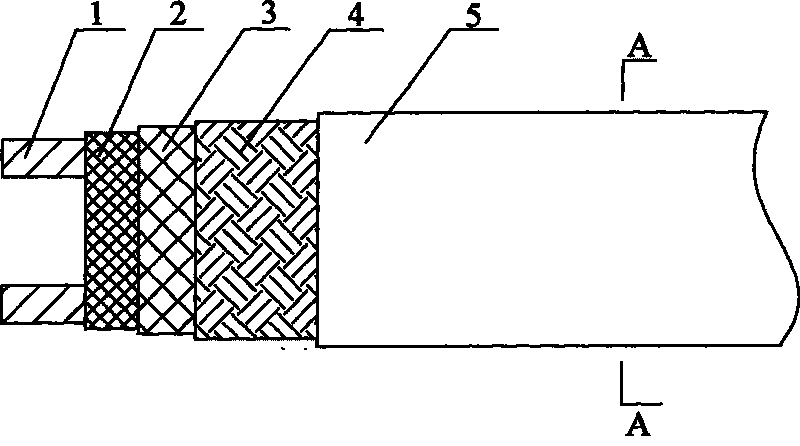

[0035] The temperature-controlled heating cable includes two metal conductive wires 1 arranged in parallel, a PTC material layer 2 , an insulating layer 3 , a shielding layer 4 and a sheath layer 5 . The metal conductive wire 1 is an annealed galvanized copper wire. A PTC material layer 2 is evenly extruded on the two parallel metal conducting wires 1 . The insulating layer 3 is wrapped on the PTC material layer 2 , the shielding layer 4 is wrapped on the insulating layer 3 , and the sheath layer 5 is set on the shielding layer 4 .

Embodiment 2

[0037] The PTC material is composed of 9.8Kg high-pressure low-density polyethylene, 1.9kg acetylene carbon ink, 1.55kg zirconia, 0.019kg4,4'-sulfurized bis(6-tert-butyl-3 methylphenol) and 0.195kg trimethanol Made from propane trimethacrylate.

Embodiment 3

[0039] The PTC material is made of 10.2kg of high-pressure low-density polyethylene, 2.1kg of acetylene carbon black, 1.57kg of zirconia, 0.019kg of 4,4'-bissulfide and 0.198kg of trimethylolpropane trimethacrylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com