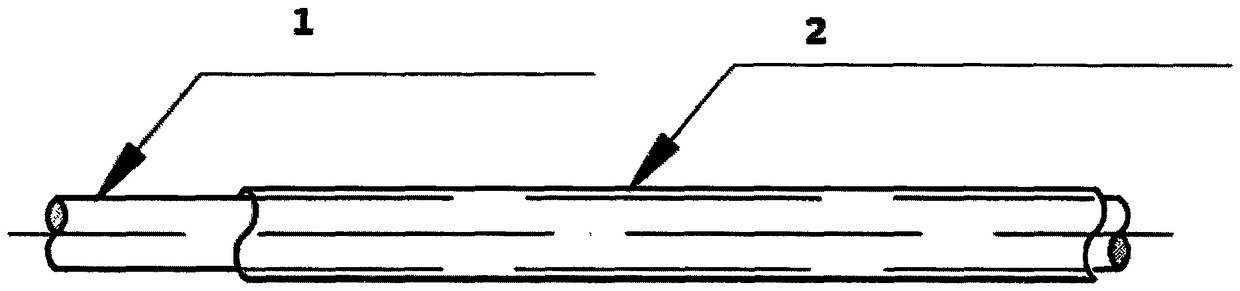

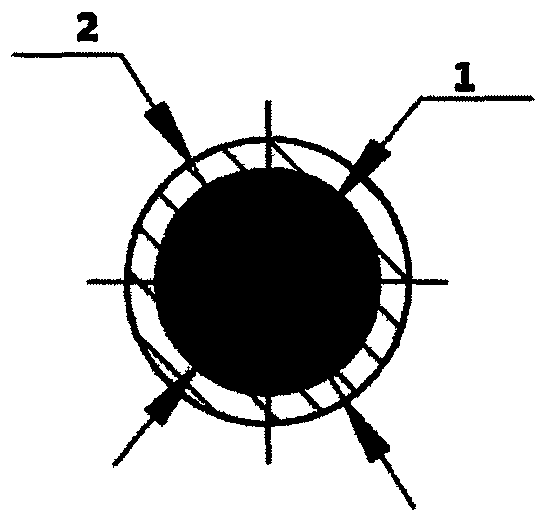

Non-metal armored wire

A kind of armored wire, non-metallic technology, applied in the field of armored wire for umbilical cables, can solve the problems of insufficient tensile strength and tensile modulus, inconvenient use, inconvenient production and assembly, etc., to achieve outstanding softness, Increased tensile strength and light specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

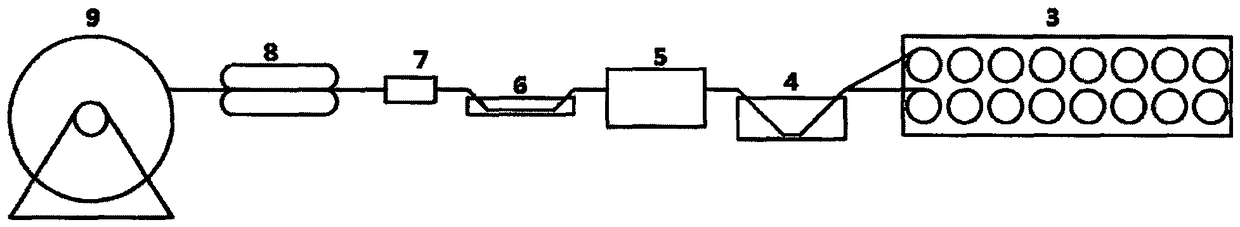

Method used

Image

Examples

Embodiment 1

[0091] Raw materials used: ultra-high molecular weight polyethylene fiber is SK78 dtex1760 ASP produced by DSM in the United States, the impregnating resin is SS-25 polyurethane resin produced by Shanghai Sunshine Polymer Co., Ltd., and the coating material is nylon 6 material AKULONяF- produced by DSM X9190 PA6.

[0092] The aforementioned method is used to prepare the non-metallic armored wire, in which three stages of heating are used for heating and curing in the mold. The first stage is 80°C, the second stage is 120°C, and the third stage is 140°C. The pulling speed of the tractor It is 1m / min. The diameter of the inner core is 2.9 mm, and the ultra-high molecular weight polyethylene fiber accounts for 75% of the weight ratio of the inner core of the non-metallic armored wire. The experimental results are shown in Table 1, Table 2, Table 3, and Table 4.

Embodiment 2

[0094] Raw materials used: ultra-high molecular weight polyethylene fiber is SK78 dtex1760 ASP produced by DSM in the United States, the impregnating resin is SS-25 polyurethane resin produced by Shanghai Sunshine Polymer Co., Ltd., and the coating material is nylon 6 material AKULONяF- produced by DSM X9190 PA6.

[0095] The aforementioned method is used to prepare the non-metallic armored wire, in which three stages of heating are used for heating and curing in the mold. The first stage is 90°C, the second stage is 120°C, and the third stage is 150°C. The pulling speed of the tractor is It is 1m / min. The diameter of the inner core is 2.9 mm, and the ultra-high molecular weight polyethylene fiber accounts for 75% of the weight ratio of the inner core of the non-metallic armored wire. The experimental results are shown in Table 1.

Embodiment 3

[0097] Raw materials used: ultra-high molecular weight polyethylene fiber is SK78 dtex1760 ASP produced by DSM in the United States, the impregnating resin is SS-25 polyurethane resin produced by Shanghai Sunshine Polymer Co., Ltd., and the coating material is nylon 6 material AKULONяF- produced by DSM X9190 PA6.

[0098]The above-mentioned method is used to prepare non-metallic armored wires, in which, three stages of heating are used for heating and curing in the mold. The first stage is 70°C, the second stage is 110°C, and the third stage is 130°C. The pulling speed of the tractor 0.5m / min. The diameter of the inner core is 2.9mm, and the ultra-high molecular weight polyethylene fiber accounts for 75% of the weight ratio of the entire non-metallic armored wire inner core. The experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com