A kind of production method of non-metallic armor wire

A production method and non-metallic technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems that restrict the development of high-performance non-metallic armored wires, the tensile strength and tensile modulus of the reinforcement layer are not conducive to control, Inconvenient to use etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

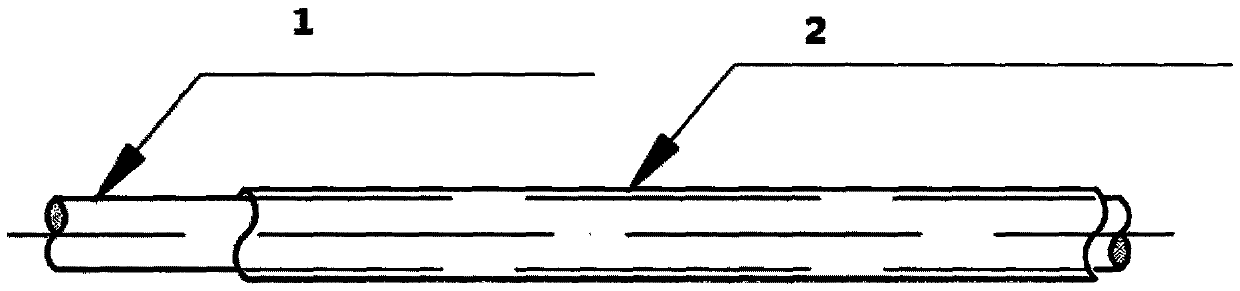

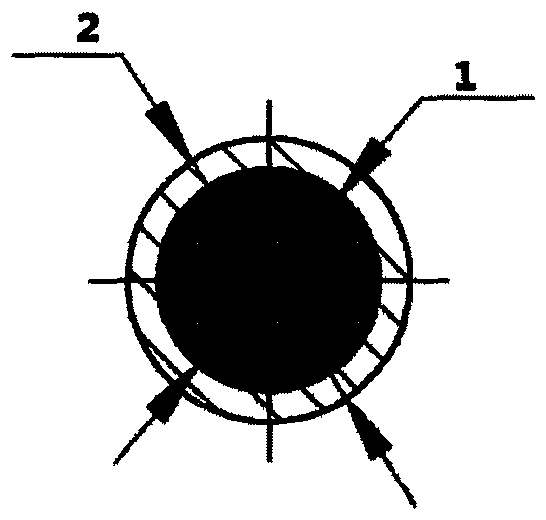

[0094] Raw materials used: ultra-high molecular weight polyethylene fiber is SK78 dtex1760 ASP produced by DSM in the United States, the impregnating resin is SS-25 polyurethane resin produced by Shanghai Sunshine Polymer Co., Ltd., and the coating material is nylon 6 material AKULONяF- produced by DSM X9190 PA6.

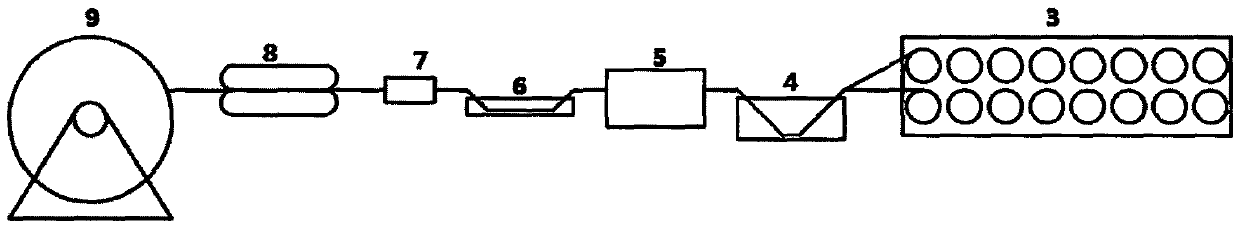

[0095] The aforementioned method is used to prepare the non-metallic armored wire, in which three stages of heating are used for heating and curing in the mold. The first stage is 80°C, the second stage is 120°C, and the third stage is 140°C. The pulling speed of the tractor It is 1m / min. The inner core diameter is 2.9 mm, and the ultra-high molecular weight polyethylene fiber accounts for 75% of the weight ratio of the entire non-metallic armored wire inner core. The experimental results are shown in Table 1, Table 2, Table 3, and Table 4.

Embodiment 2

[0097] Raw materials used: ultra-high molecular weight polyethylene fiber is SK78 dtex1760 ASP produced by DSM in the United States, the impregnating resin is SS-25 polyurethane resin produced by Shanghai Sunshine Polymer Co., Ltd., and the coating material is nylon 6 material AKULONяF- produced by DSM X9190 PA6.

[0098] The aforementioned method is used to prepare the non-metallic armored wire, in which three stages of heating are used for heating and curing in the mold. The first stage is 90°C, the second stage is 120°C, and the third stage is 150°C. The pulling speed of the tractor is It is 1m / min. The inner core diameter is 2.9 mm, and the ultra-high molecular weight polyethylene fiber accounts for 75% of the weight ratio of the entire non-metallic armored wire inner core. The experimental results are shown in Table 1.

Embodiment 3

[0100]Raw materials used: ultra-high molecular weight polyethylene fiber is SK78 dtex1760 ASP produced by DSM in the United States, the impregnating resin is SS-25 polyurethane resin produced by Shanghai Sunshine Polymer Co., Ltd., and the coating material is nylon 6 material AKULONяF- produced by DSM X9190 PA6.

[0101] The above-mentioned method is used to prepare non-metallic armored wires, in which, three stages of heating are used for heating and curing in the mold. The first stage is 70°C, the second stage is 110°C, and the third stage is 130°C. The pulling speed of the tractor 0.5m / min. The inner core diameter is 2.9 mm, and the ultra-high molecular weight polyethylene fiber accounts for 75% of the weight ratio of the entire non-metallic armored wire inner core. The experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com