Outdoor insulative supporting terminal

A terminal, outdoor technology, used in insulators, electrical components, circuits, etc., can solve the problems of poor mechanical strength, inconvenient installation, easy to break, etc., and achieve the effects of good electrical performance, high production efficiency, and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

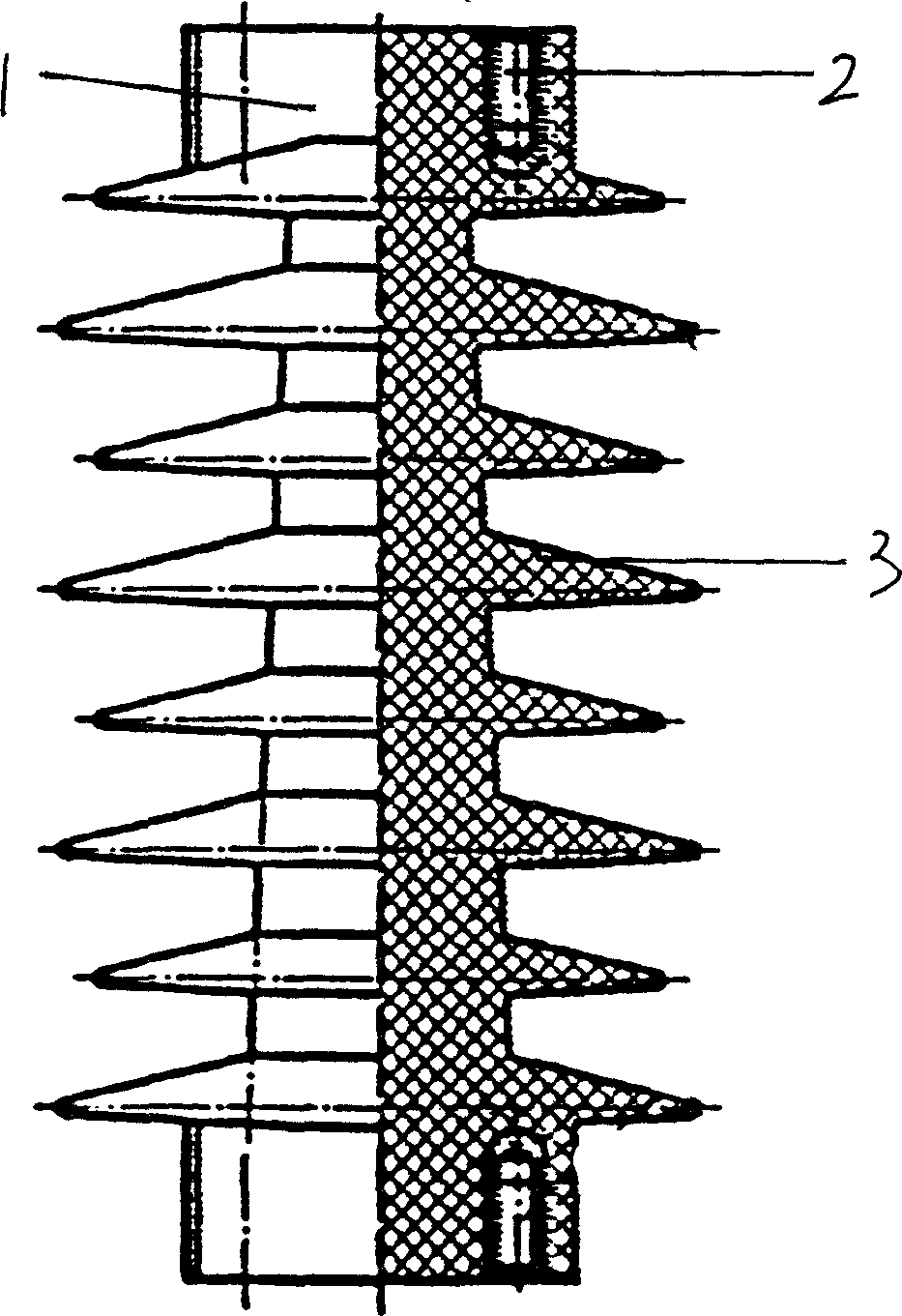

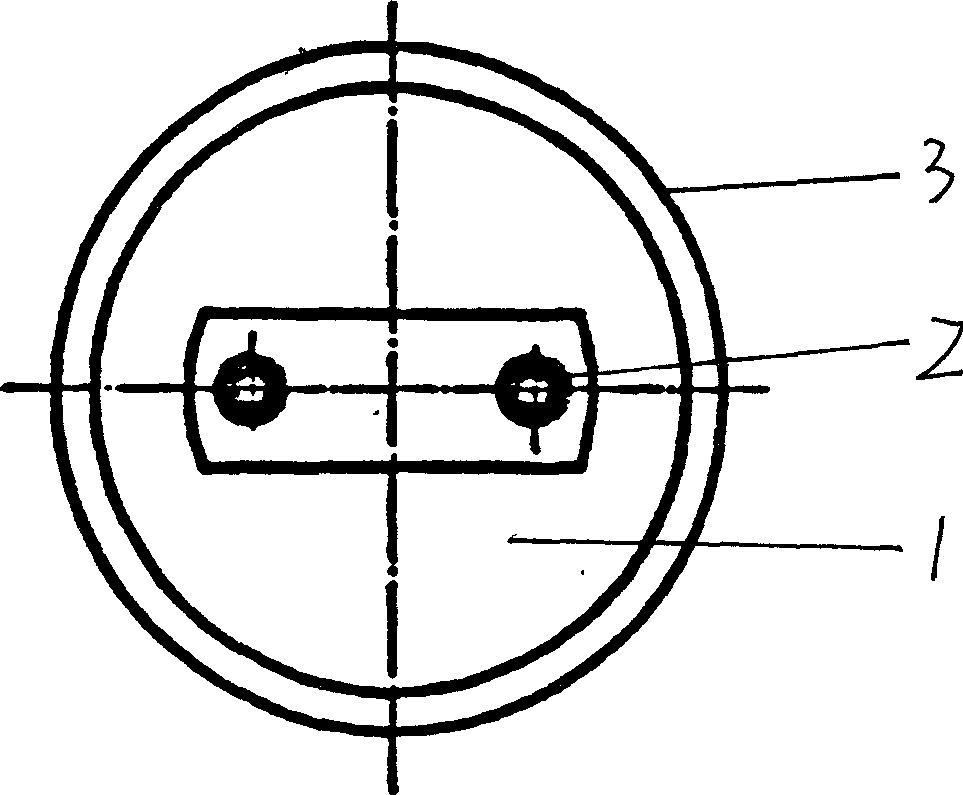

[0009] As shown in the figure, the outdoor insulating support terminal 1 of the present invention is made of outdoor epoxy resin, modified acid anhydride as a fixing agent, silicon micropowder as a filler, polyether as a toughening agent, and benzyldimethylamine as an accelerator. Color paste, according to the ratio of epoxy resin 100: fixing agent 100: filler 370: toughening agent 2: accelerator 0.15: color paste 1.2, after APG process, there are metal inserts 2 and terminals for fixing screws at both ends body together by die-casting and solidification, the length of the supporting terminal is small, only 320-350mm, and the supporting terminal skirt 3 is an umbrella-shaped sheet structure with a slope of 13-16°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com