Method and apparatus for continuously manufacturing fastener stringer

一种制造设备、制造方法的技术,应用在金属加工设备、应用、服饰等方向,能够解决动杠杆强度提高、设备尺寸增大等问题,达到滑动阻力减小、平稳打开和闭合操作、优良触感的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

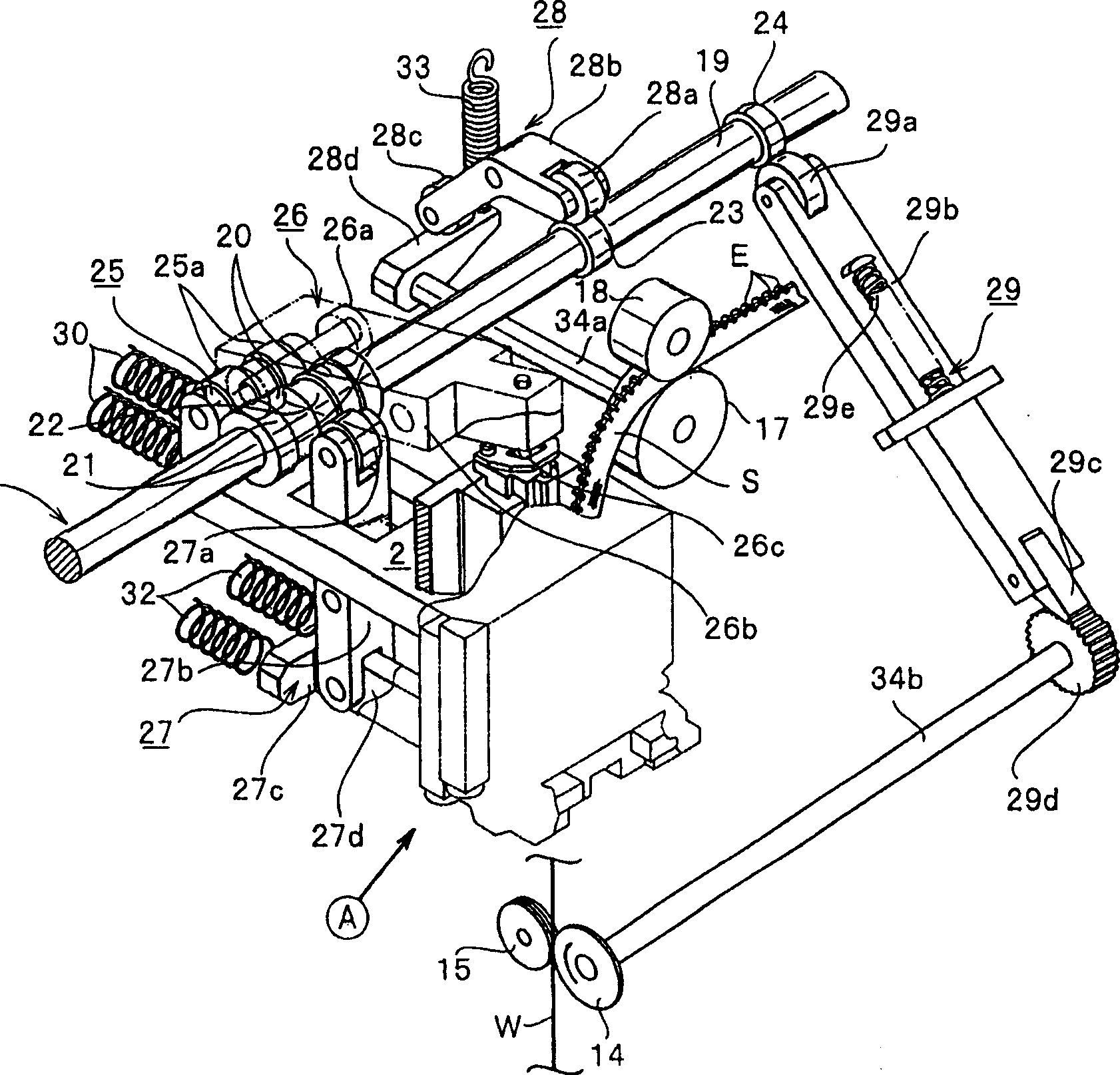

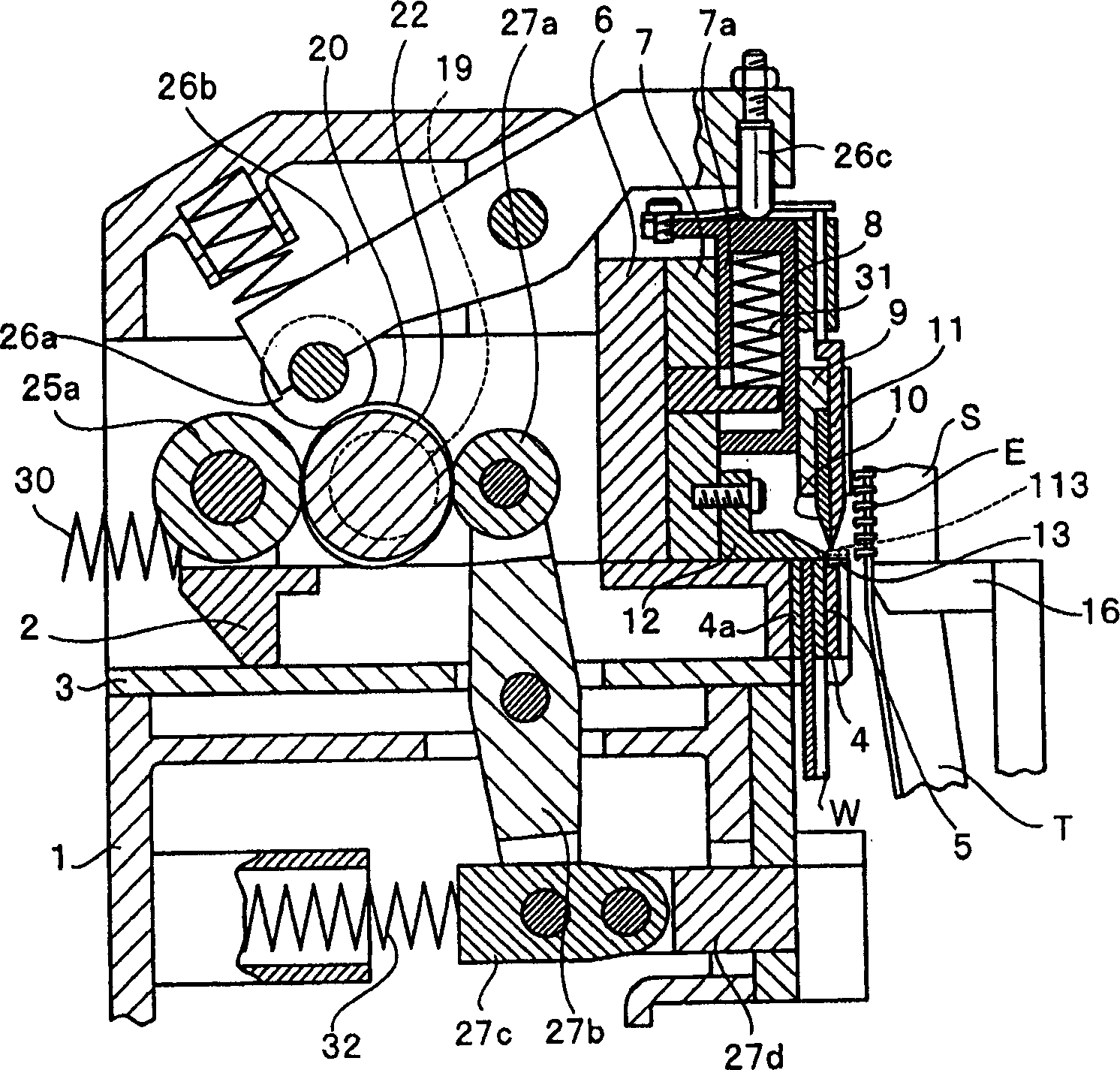

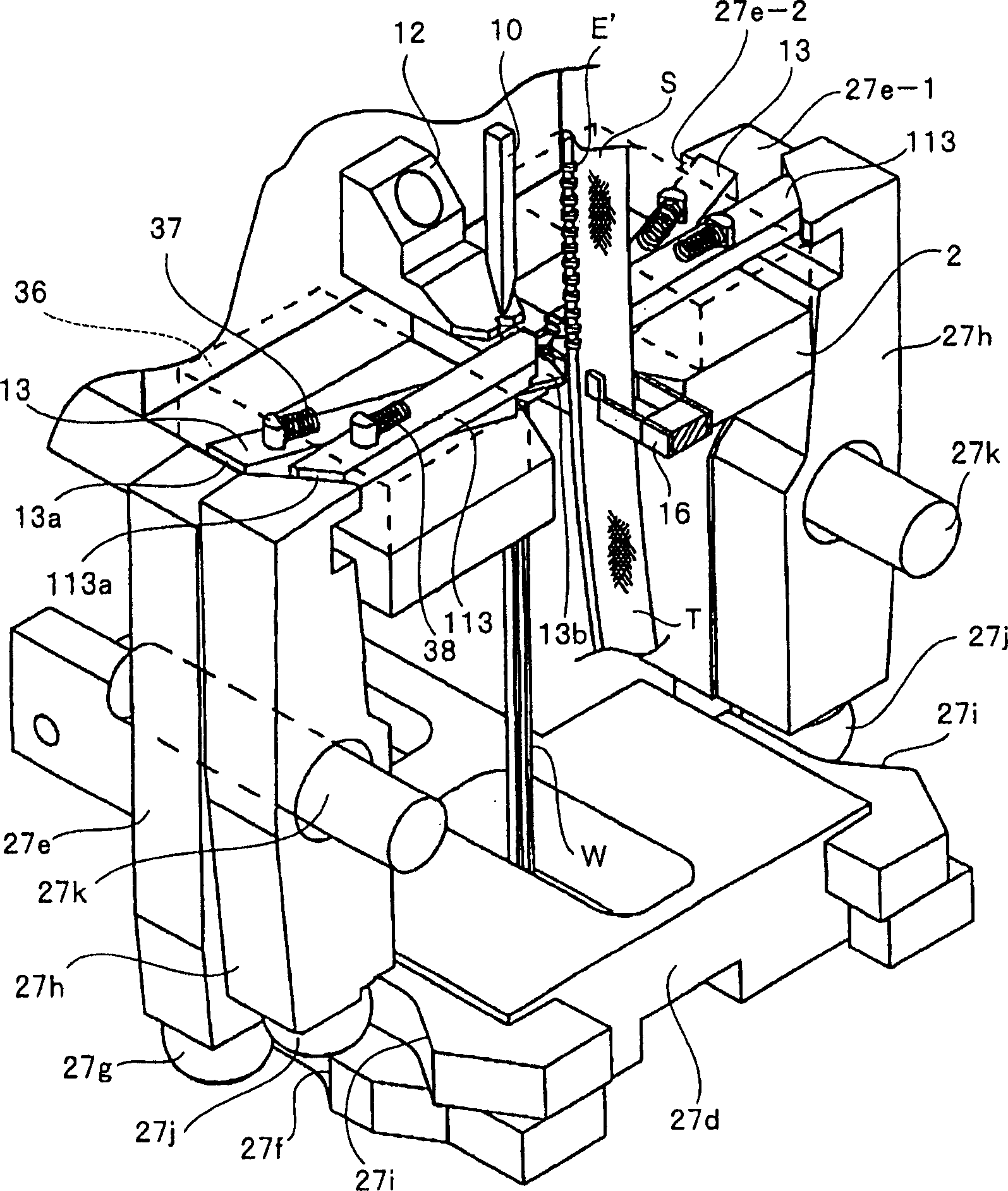

[0027] Hereinafter, preferred embodiments of the present invention will be specifically described with reference to the drawings.

[0028] Here, the method and apparatus for continuous manufacturing of a fastener chain of the present invention are not different from the conventional method and apparatus disclosed in Japanese Patent Publication No. 59-51813 in the following respect: an engagement element having a substantially Y-shaped cross-section obtained by a rolling process The wire is cut to a thickness corresponding to a single engaging element with a cutting punch, the engaging head is formed into a mountain-like shape, and then the engaging element is implanted on the required part of the zipper tape by pressing the additional leg with a pressure hammer to Continuously manufacture zipper chain.

[0029] The most remarkable feature of the present invention is not that: as disclosed in Japanese Patent Application Publication No. 8-56714, when the additional leg L of the enga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com