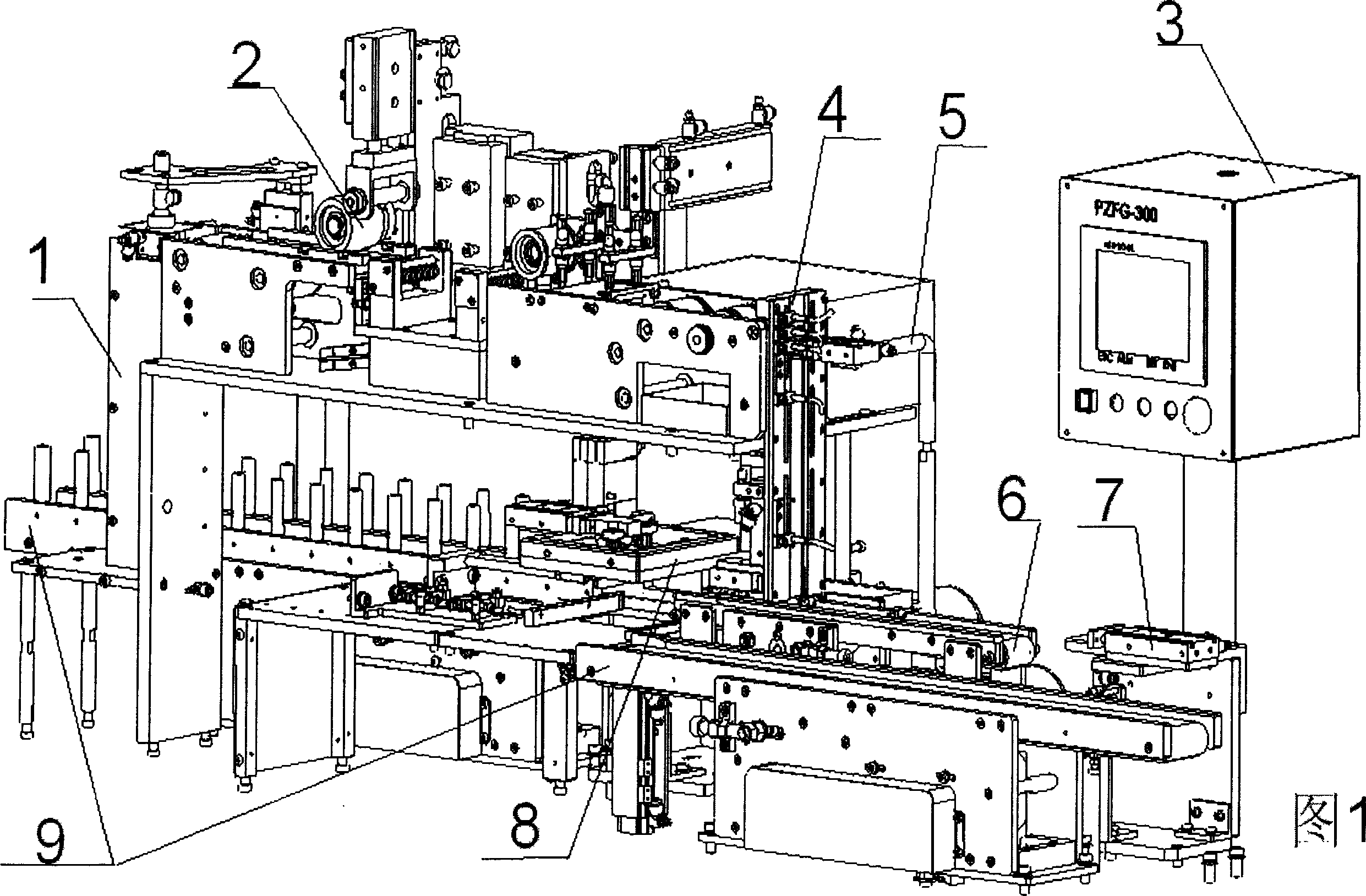

Automatic once slicer for chip resister

A fully automatic, dividing machine technology, applied in the direction of resistors, resistor manufacturing, non-adjustable metal resistors, etc., can solve the problems of high price, affecting the quality of chip resistors, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

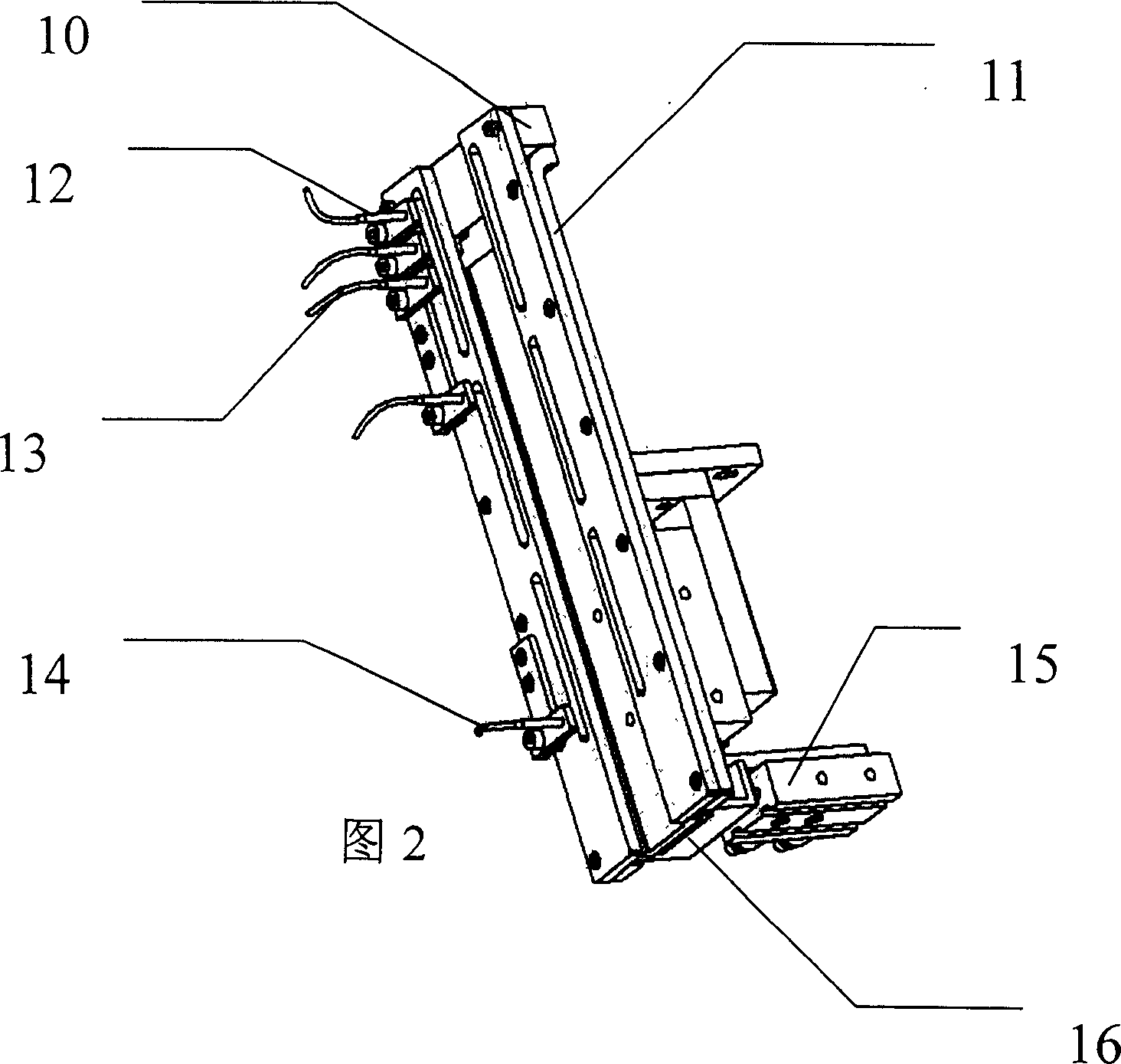

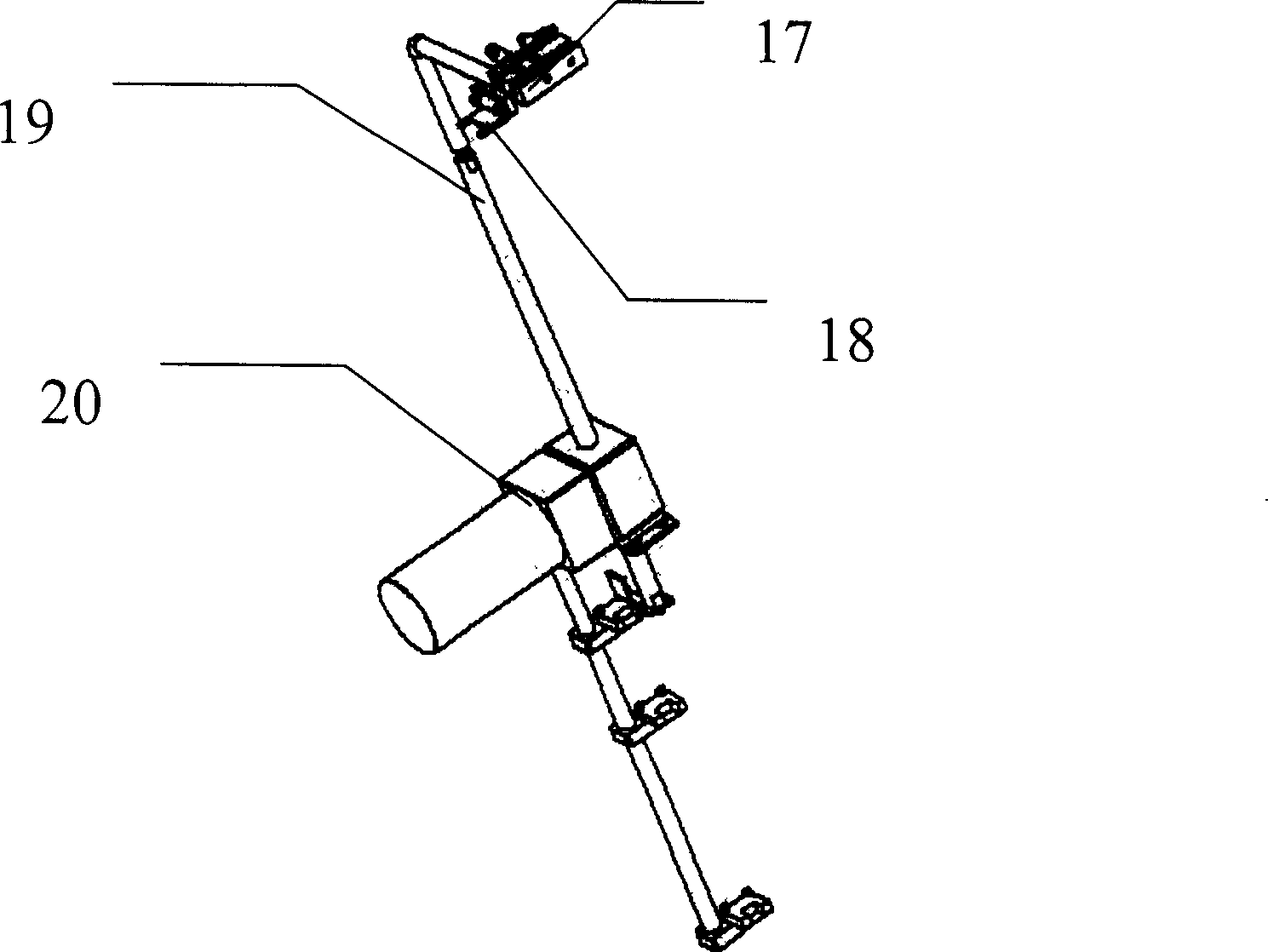

[0017] First, put the resistive ceramic substrate on the pallet in the feeding box of the feeding device 1. After the feeding motor runs, the supporting rod rises to the cutting plane, and the suction cup puts it on the rotating conveyor belt and transports it to When dividing the lower part of device 2, it is divided by the front for the first time. At this time, the substrate is still connected and not completely separated, and then it is passed forward for the second reverse division, and the substrate is completely divided into resistance strips. There is no connection between them, and after the white edges are removed and the separation is accelerated, there is a certain distance between the side-by-side resistance strips to prevent the resistance strips from piling up when entering the resistance strip baffle plate 11, and to prevent the resistance strips ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap