Mobile denture/ fixed bridge false tooth inlaid process and its utensil

A technology for fixing bridges and dentures, which is used in dental tools, educational appliances, dentistry, etc., and can solve problems such as irreparability, matching of oral soft tissues, and large deformation errors of models.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] Restoration process of removable dentures (including full dentures):

[0007] (1) The production process of the impression (bite print) is the same as that of the conventional impression.

[0008] (2) Occlusal recording process, use impression glue to make occlusal records, and obtain the correct position of upper and lower teeth occlusal.

[0009] (3) Working model (positive model) manufacturing process, pouring the model with plaster of paris.

[0010] (4) Operate the model (secondary model) manufacturing process, pour the secondary model with superhydrite immediately after the positive model is demoulded.

[0011] (5) Fix the upper and lower jaw models on the articulator (articulator) according to the occlusal records.

[0012] (6) After making appropriate corrections to the positive model, draw out the edge of the denture base.

[0013] (7) According to the specific situation of the patient, stainless steel wires are used to make restoration parts such as retaini...

Embodiment 2

[0018] Embodiment 2: The manufacturing process of fixed abutments has the following steps:

[0019] (1), (2), (3), (4), (5), (6) process is identical with embodiment 1.

[0020] (7), saw the interdental gap of the retention abutment on the positive mold, first saw the interdental gap of the retention abutment on the secondary model, measure the height of the neck of the retention abutment and its circumference (including The length of the connecting rod), cut a piece of white metal, the width and length of which are the same as the height and circumference of the above-mentioned abutment neck. The thickness of the white metal sheet used to make the retaining sleeve and ring is only 0.2mm, so only 0.1mm of the adjacent real teeth need to be ground, so the damage to the teeth is small.

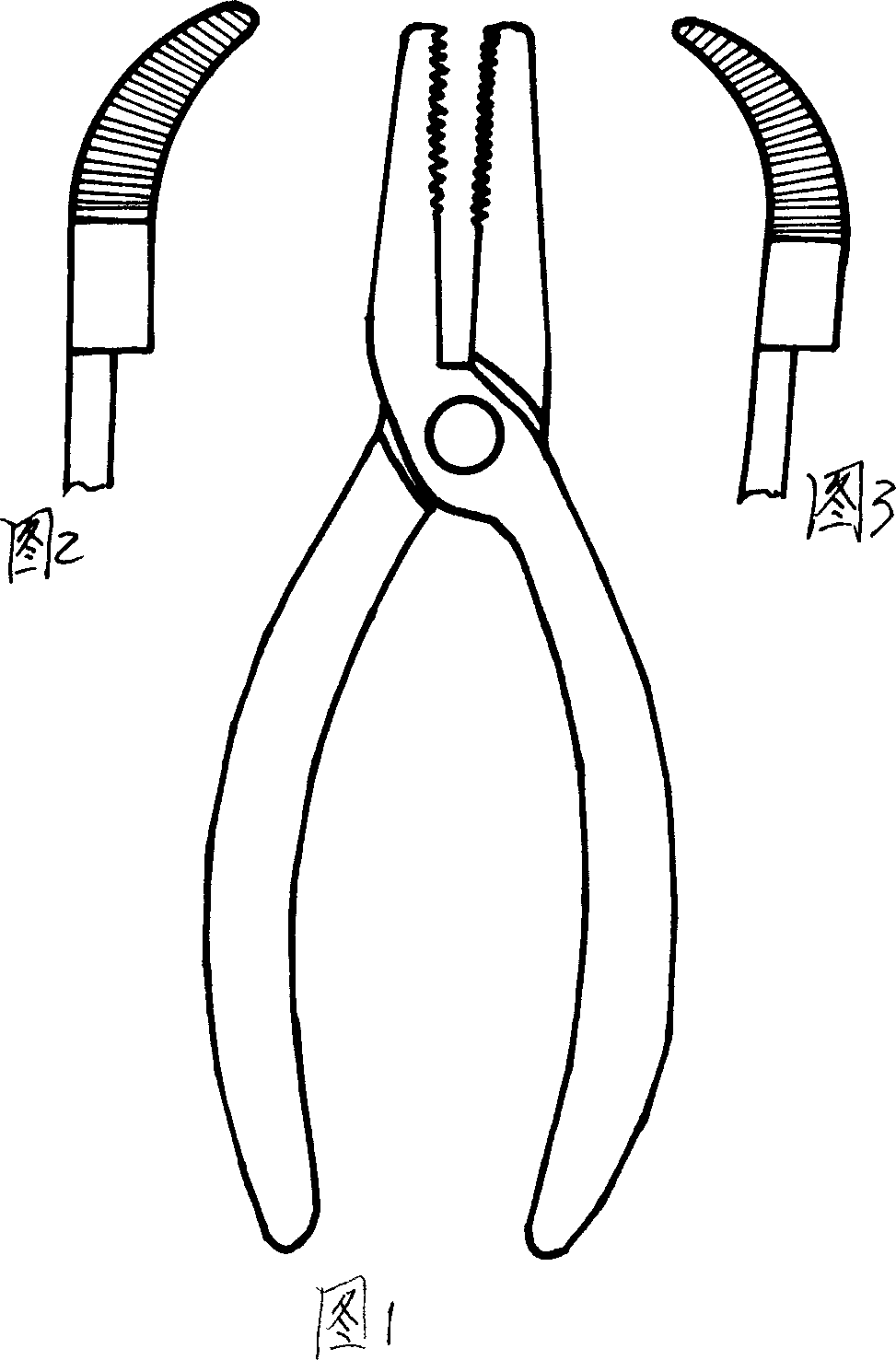

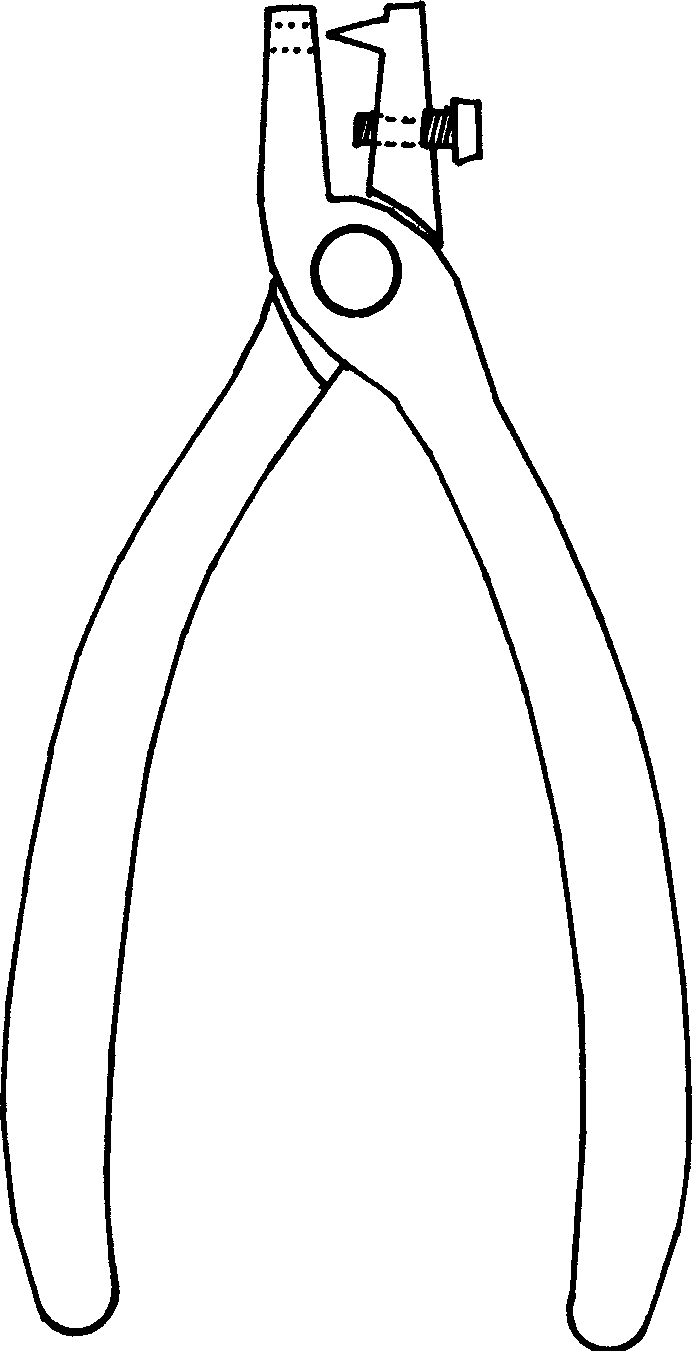

[0021] (8), make retainer cover, ring operation; Make retainer cover, ring on the retaining abutment of secondary mold with above-mentioned white metal sheet. The nailing pliers can be used fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com