Engine carrier and shock-absorbing bearing structure employing the carrier

A technology for engine mounts and mounting components, which is applied in power units, transportation and packaging, non-rotational vibration suppression, etc., can solve problems such as increased production costs, difficulty in adoption, and large installation space, so as to reduce production costs and avoid adverse effects , the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

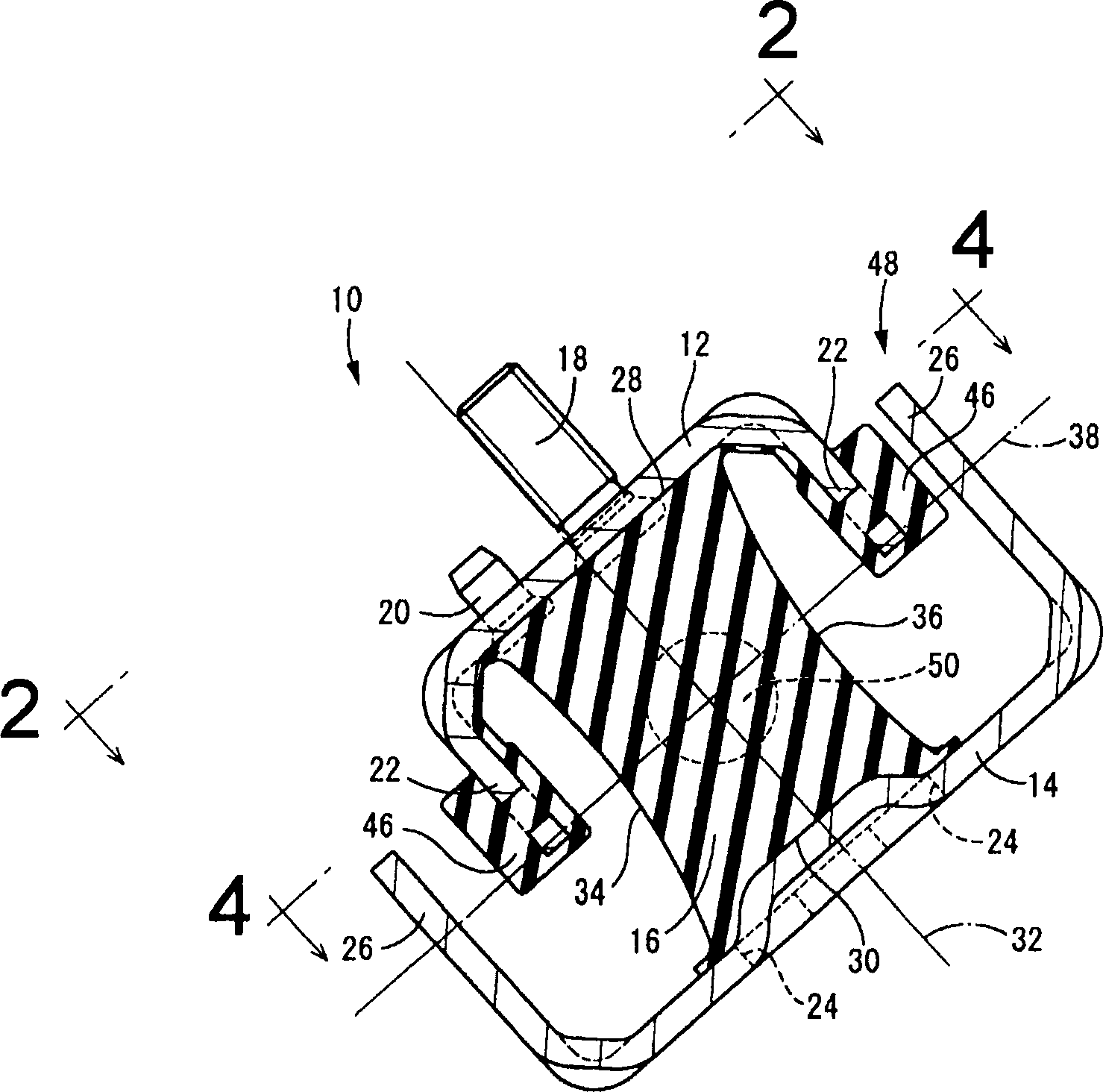

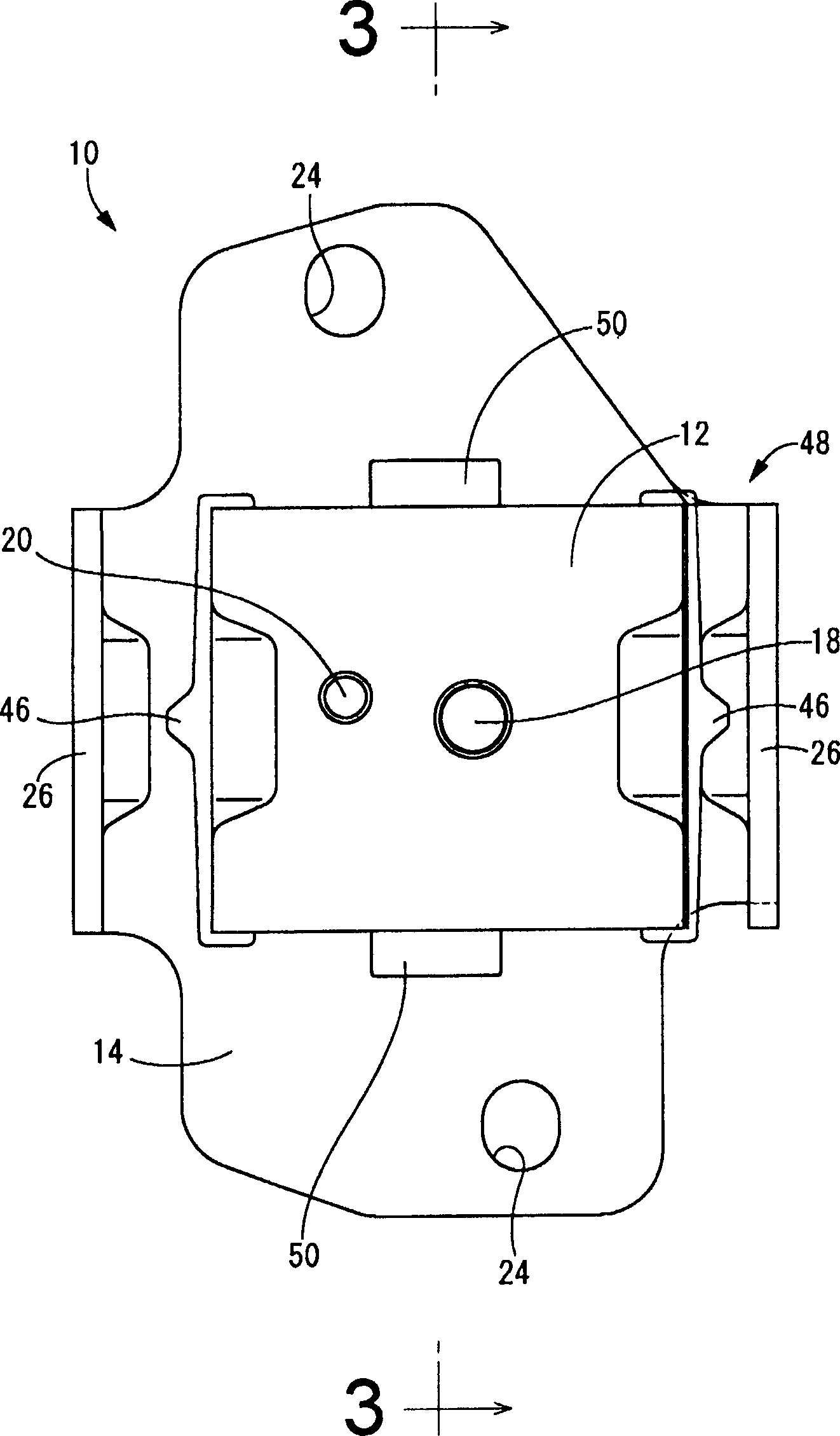

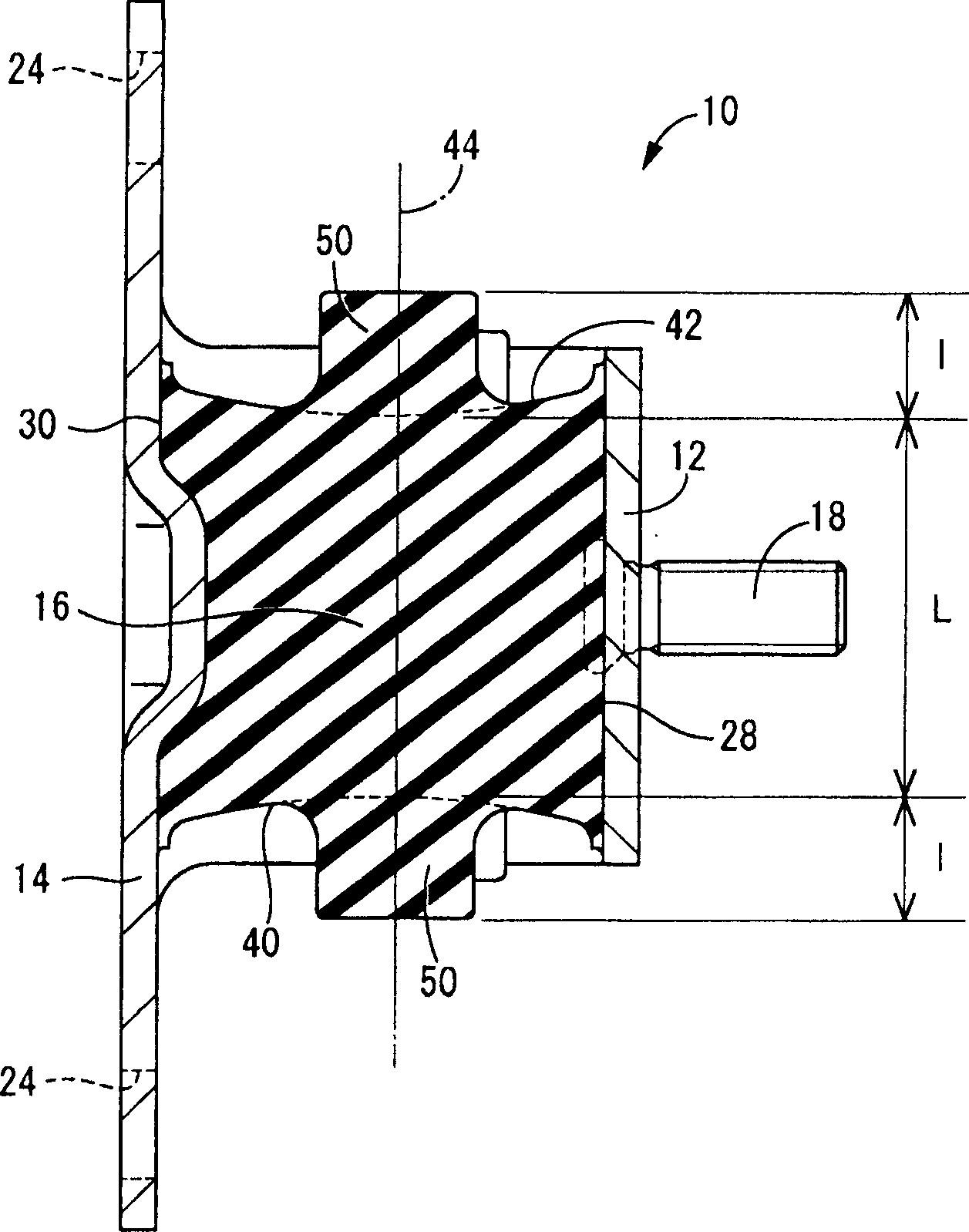

[0032] first reference Figure 1-4 , which shows an engine mount 10 according to an embodiment of the present invention. The engine mount 10 includes a metal upper mounting member 12 and a metal lower mounting member 14 separated by a predetermined distance and connected together with a main rubber elastic body 16 therebetween. In the following descriptions, unless otherwise stated, the vertical direction refers to the figure 1 in the up-down / vertical direction.

[0033] More specifically, the upper mounting member 12 has a generally rectangular flat plate shape and is made of a rigid material such as metal or the like. A fastening bolt 18 protruding therefrom is integrally formed near the center of the upper mounting member 12 , and a generally cylindrical protrusion 20 with a small diameter protrudes at a position off the center.

[0034] In the transverse direction of the upper mounting member 12 ( figure 2 A pair of upper stopper portions 22 are integrally formed at b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com