Track plate reinforcing mattress insulated binding method

A steel mesh and track slab technology, applied in the field of steel bar binding, can solve the problems of increased cost and shortened signal transmission distance, and achieve the effect of convenient binding and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

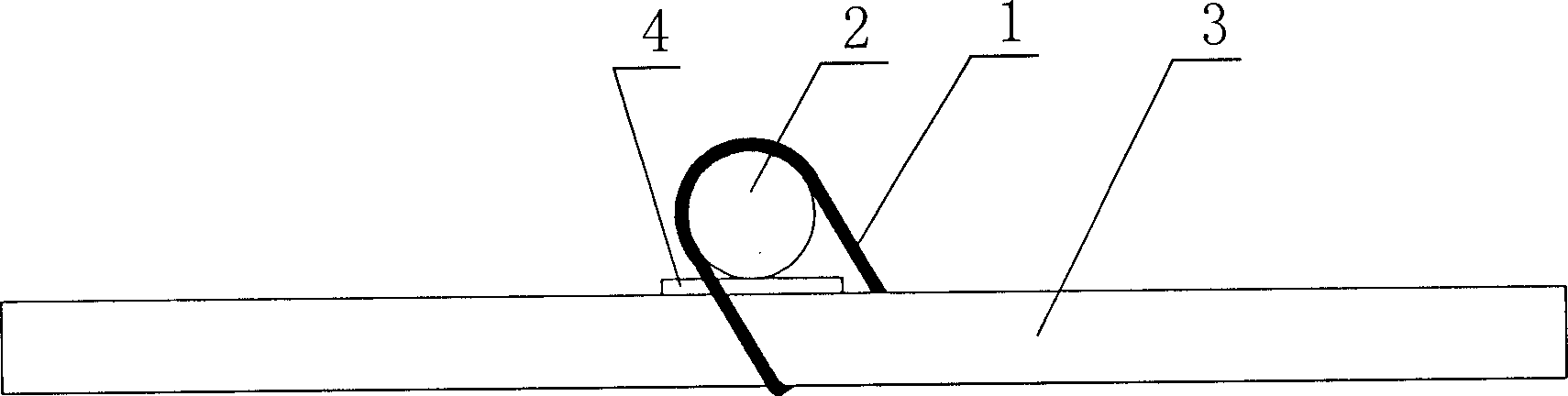

[0011] like figure 1 As shown in the figure, a method for insulating tie-up of reinforcing mesh of track slab is used to bind longitudinal reinforcing bar 2 and horizontal reinforcing bar 3 nodes of reinforcing mesh inside the track slab with insulating binding wire 1, and there is insulation between the longitudinal reinforcing bar 2 and horizontal reinforcing bar 3 nodes. Pad 4, insulation binding wire 1 is a plastic binding wire.

Embodiment 2

[0013] like figure 1 As shown in the figure, a method for insulating tie-up of reinforcing mesh of track slab is used to bind longitudinal reinforcing bar 2 and horizontal reinforcing bar 3 nodes of reinforcing mesh inside the track slab with insulating binding wire 1, and there is insulation between the longitudinal reinforcing bar 2 and horizontal reinforcing bar 3 nodes. Pad 4, insulating binding wire 1 is epoxy resin insulating coated iron wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com