Weighing apparatus and method for liquid crystal display glass raw materials

A liquid crystal display and weighing device technology, which is applied in the field of weighing devices for liquid crystal display glass raw materials, can solve problems affecting the weighing accuracy of raw materials, weighing accuracy fluctuations, and weighing accuracy drops, so as to ensure the weighing accuracy , Guarantee the accuracy and avoid the effect of weighing fluctuation

Inactive Publication Date: 2006-10-25

HENAN ANCAI HI-TECH +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method is not conducive to the accuracy assurance of less raw materials, and will easily lead to a decrease in weighing accuracy. The reasons are as follows

[0004] 1. As we all know, when the weighing quantity of a certain raw material is less than 15kg, and its accuracy is required to be greater than 1 / 1000 or higher, the minimum scale of the electronic scale is generally less than 5g, so that the weighing accuracy of the electronic scale is easily affected by ingredients. Due to the influence of the airflow and air pressure generated by the mixer during the process, the weighing value will fluctuate, thus affecting the accuracy of raw material weighing

[0005] 2. After the weighing is completed, the raw materials will more or less adhere to the conveying pipeline when they are discharged into the mixer. For raw materials with a weighing quantity less than 15kg and a small amount, less adhesion will easily cause Fluctuations in Weighing Accuracy

[0006] These problems will cause the weighing accuracy of less raw materials to meet the requirements of the batching process, resulting in fluctuations in the composition of small amounts of raw materials (weighing quantity less than 15kg) in each batch of batches, making the homogenization and clarification of the glass melting change. Poor, in severe cases, the bubbles in the glass will increase, reducing the yield of glass

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific example

[0034] The invention can prevent fluctuations and sticky materials in the process of weighing and transporting less raw materials. The concrete example of the implementation method of the present invention sees below:

[0035] electronic scale

[0036] Note: The adhesion amount of raw material 1 was measured by chemical analysis.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

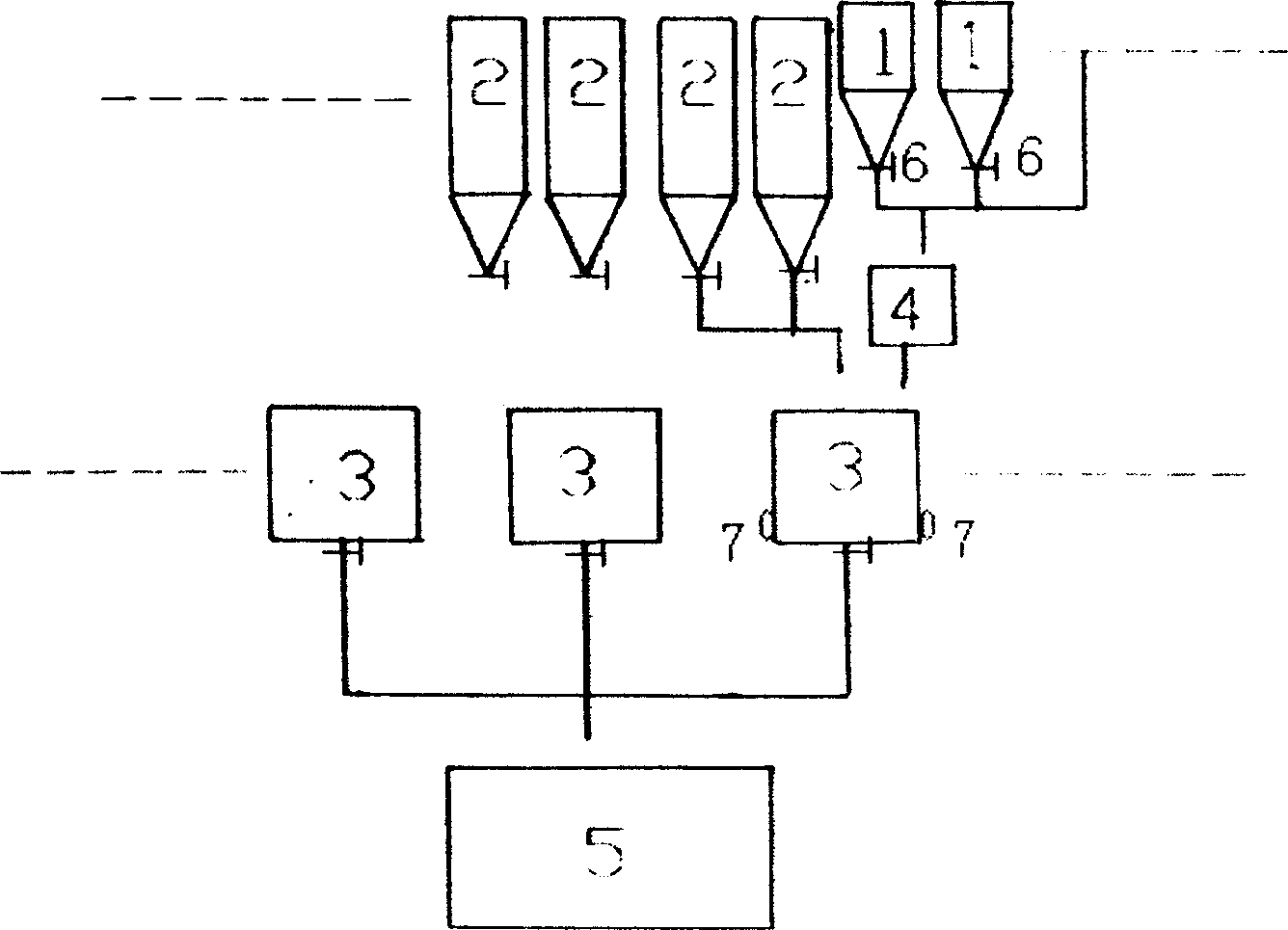

The invention relates to a high-accuracy weighing device and method for raw materials for liquid crystal display glass. And the device comprises a high accuracy electric scale for accurately weighing smaller numbers of raw materials and an electric scale for weighing larger numbers of raw materials, where the material outlet of the former is connected through the lower paddle with the material inlet of the latter, and the material outlet of the latter is connected with a material mixer; firstly the smaller numbers of raw materials are added in sequence to the high accuracy electronic scale for accurate weighing and after this, they enter through the other electronic scale into the material mixer, thus able to assure the weighing accuracy of the smaller numbers of raw materials and further improve the preparing quality of the auxiliary materials.

Description

technical field [0001] The invention relates to the technical field of liquid crystal display glass production, in particular to a weighing device and a weighing method for liquid crystal display glass raw materials for high-precision weighing of liquid crystal display glass raw materials. Background technique [0002] In the liquid crystal display glass production process, the weighing accuracy of raw materials is very high. The weighing accuracy mentioned here refers to the accuracy of the actual value of the weighed raw materials entering the mixer. However, for raw materials with a small amount of ingredients (weighing ≤ 15kg each time), it is difficult to ensure high weighing accuracy (weighing accuracy greater than 1 / 1000) according to the usual weighing method. However, these raw materials play a role in clarifying, homogenizing and changing the characteristics of glass in the melting of glass. The accuracy of its weighing directly affects the melting and performance...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03B1/00

Inventor 贾伟苍利民孟军恒闫冬成付玉川

Owner HENAN ANCAI HI-TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com