Movable universal eva porating source apparatus for vacuum system

A technology of vacuum system and evaporation source, which is applied in the direction of vacuum evaporation plating, ion implantation plating, metal material coating process, etc., and can solve the problems of multi-space, low efficiency, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

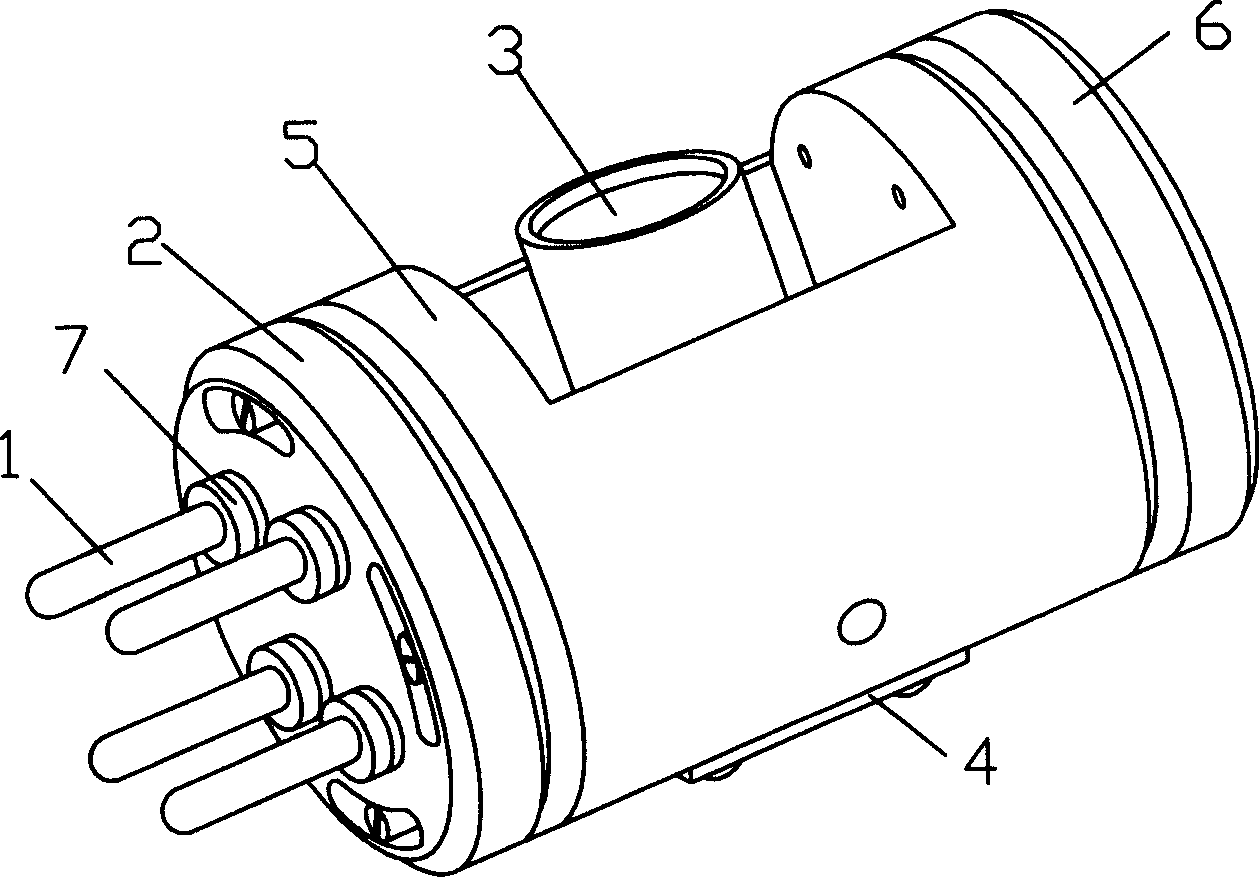

[0016] Such as figure 1 As shown, the movable and universal evaporation source device used in the vacuum system of the present invention includes a pluggable electrode 1, a receiving and supporting part 2, an evaporation source 3, an evaporation source adjustment frame 4, an evaporation source fixing frame 5 and a transmission rod receiving Part 6;

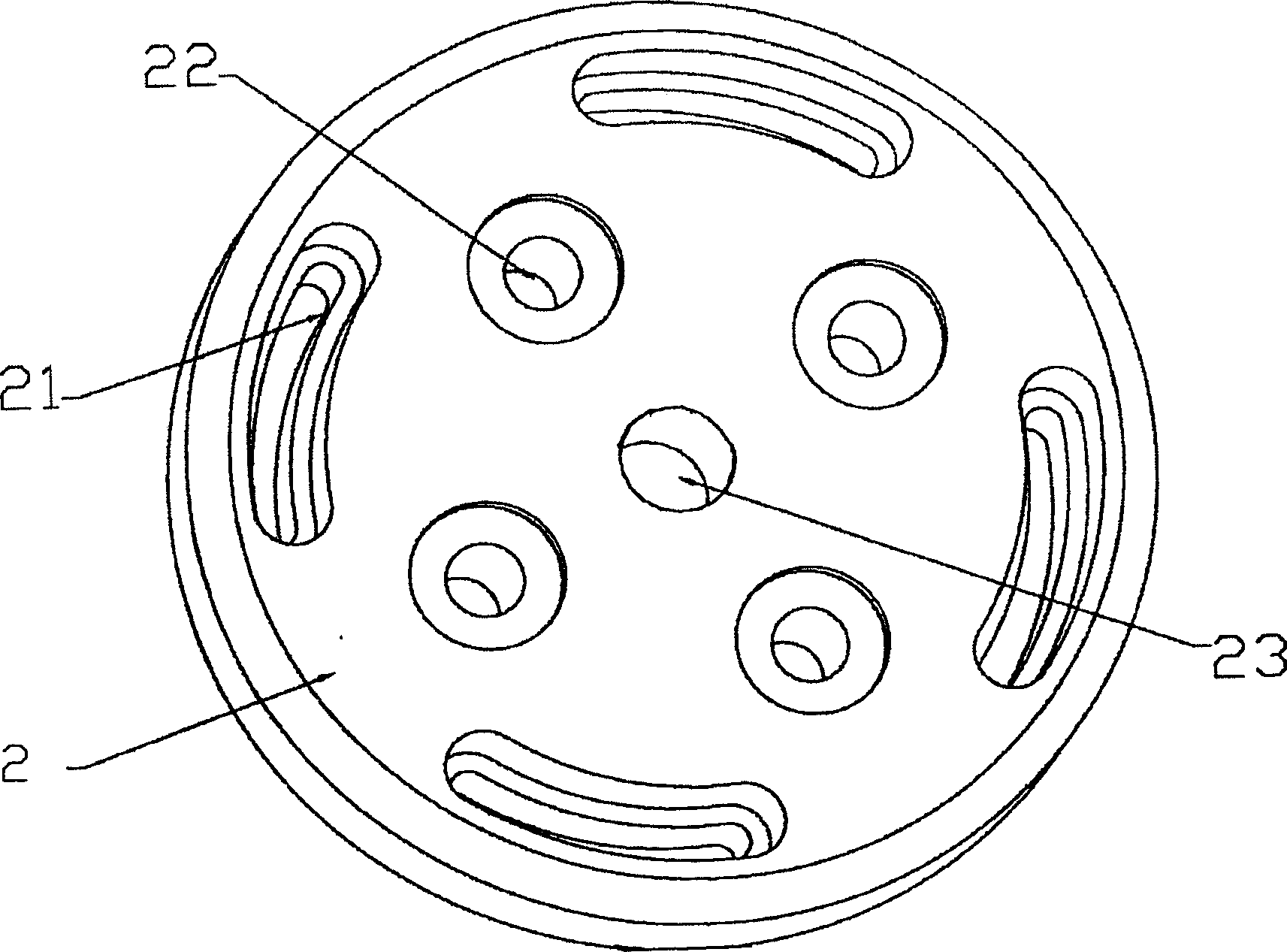

[0017] Such as image 3 As shown, the geometric center of the receiving and supporting part 2 is provided with a support port 23 for connecting to the receiving platform, and the outside of the support port 23 is provided with electrode sockets 22 and fixed ports 21 in sequence, and the number of electrode sockets 22 corresponds to the number of electrodes 1, The electrode socket 22 includes two outer holes and a middle hole located between the two outer holes. Ceramic insulating sheets 7 closely matched with the outer holes are arranged in the two outer holes. The thickness of the ceramic insulating sheets 7 is greater than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com