Engine camshaft transmission

A transmission device and camshaft technology, which is applied to engine components, machines/engines, valve devices, etc., can solve the problems of inability to rotate synchronously, large transmission torque, and small wear, and achieve accurate transmission, large transmission torque, and small wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

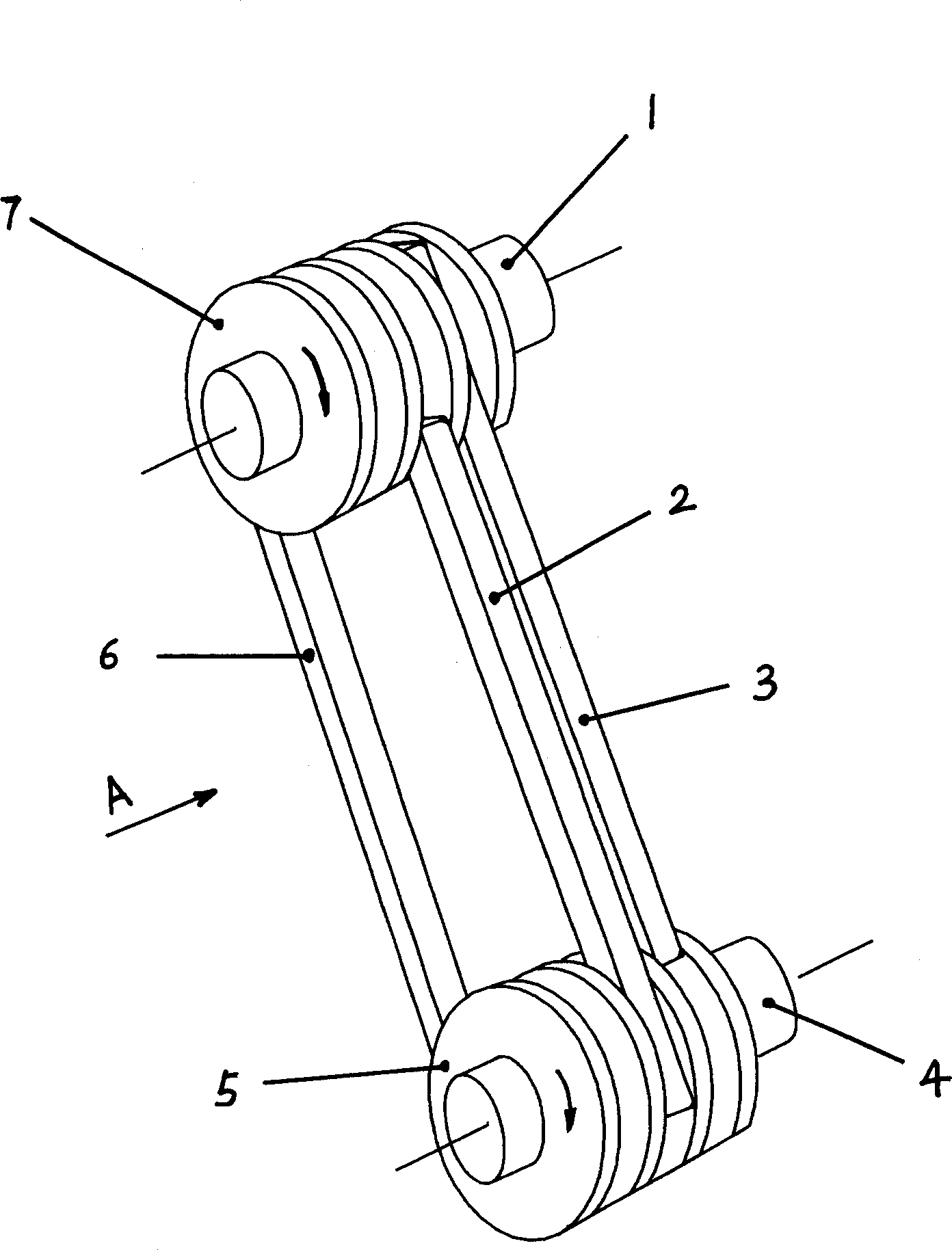

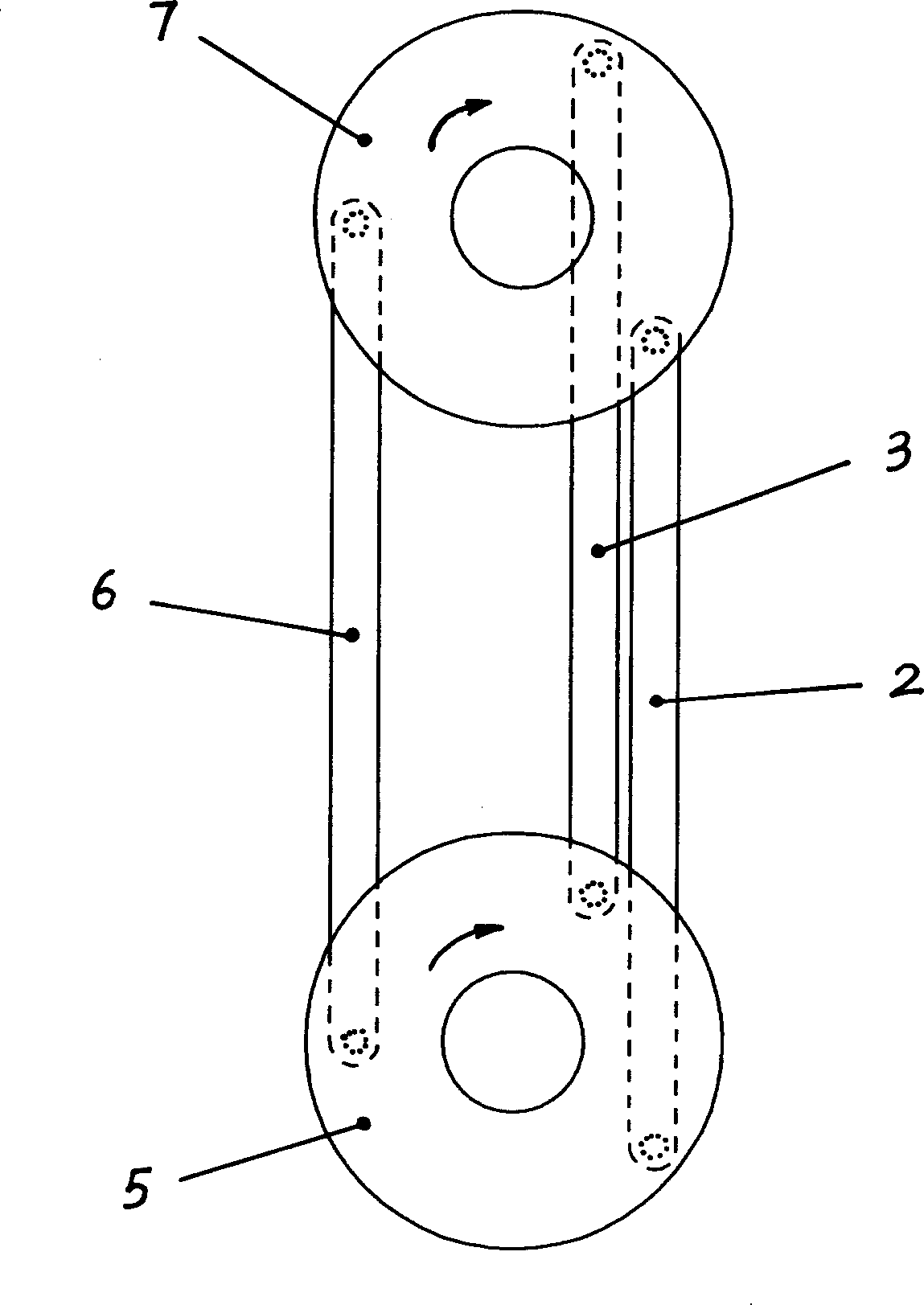

[0010] combine figure 1 and figure 2 , the engine camshaft transmission of embodiment, comprise engine crankshaft 4 and camshaft 1, the crankshaft that is respectively provided with identical rotation diameter on engine crankshaft 4 and camshaft 1, is respectively driving crankshaft 5 and driven crankshaft 7, and crankshaft is three The roads are evenly arranged and distributed at 120°. Each corresponding two roads of the driving crankshaft 5 and the driven crankshaft 7 are connected by connecting rods. There are three connecting rods in total, namely the front connecting rod 6, the middle connecting rod 2, and the rear connecting rod pole 3.

[0011] Due to the arrangement of three connecting rods, the problem that the driven crankshaft lags behind the driving crankshaft and cannot rotate synchronously when one connecting rod reaches the upper and lower dead centers is avoided, and the purpose of accurate transmission is achieved.

[0012] There is a bearing between the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com