Internal combustion engine cylinder liner

A technology for an internal combustion engine and a cylinder liner, applied to the field of the cylinder liner of an internal combustion engine, can solve problems such as major accidents, broken connecting rod screws, and scrapping of the whole machine, and achieve the effects of improving work efficiency, prolonging service life, and reducing maintenance times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

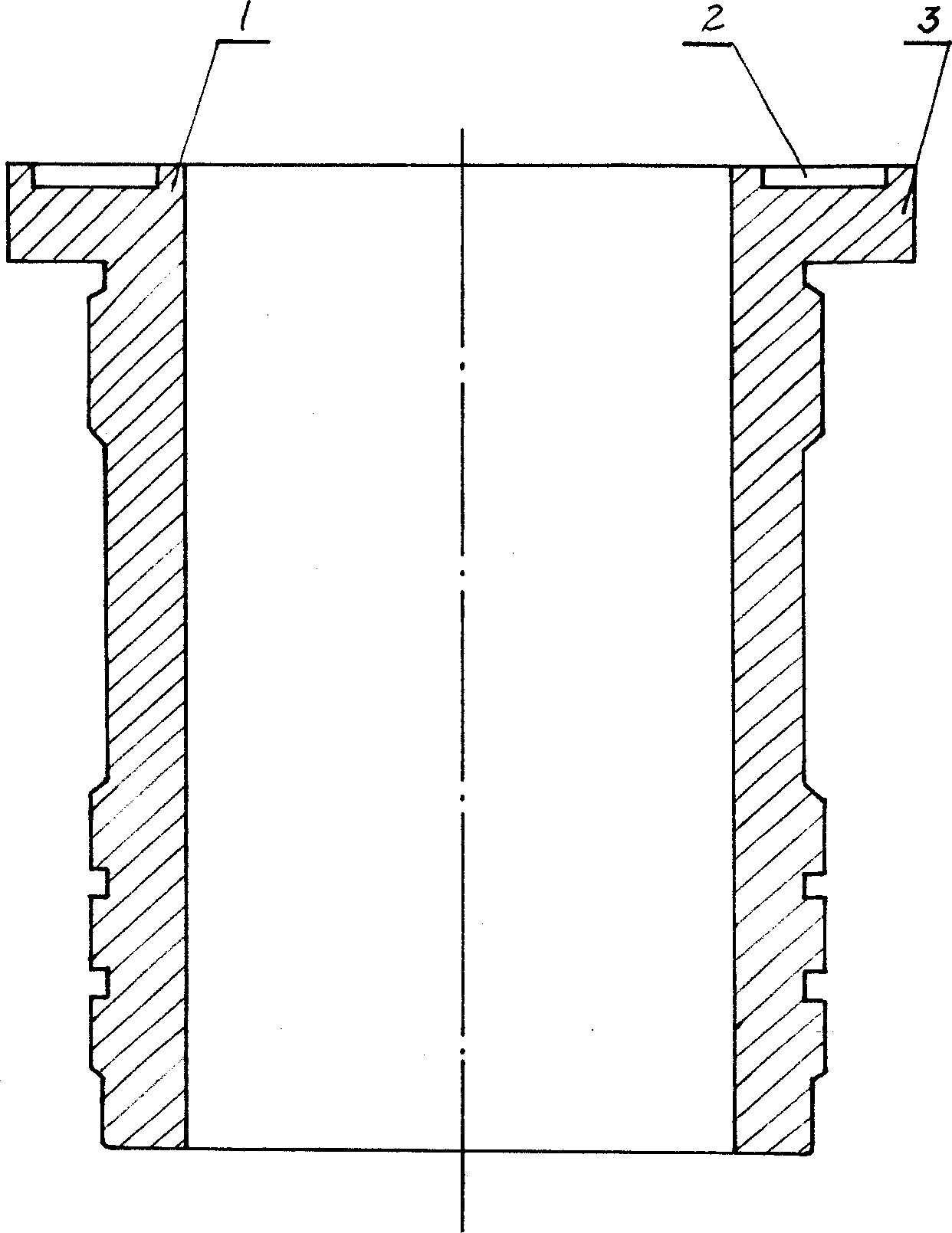

[0021] Embodiment 1, as figure 1 Shown: the top of the existing cylindrical cylinder liner 1 is provided with an annular gasket groove 2. The height of the boss 3 on the top of the cylinder liner 1 can be adjusted accordingly as required. When in use, the cylinder liner 1 is connected to the cylinder head through a connecting piece, and there is a gasket made of metal material coated asbestos board or other non-metallic materials in between, and the gasket sinks into the gasket groove 2 under the pressure of the connecting piece middle. In this way, it can be ensured that the gasket is not in place when the internal combustion engine is working, thereby ensuring the reliability of the seal.

Embodiment II

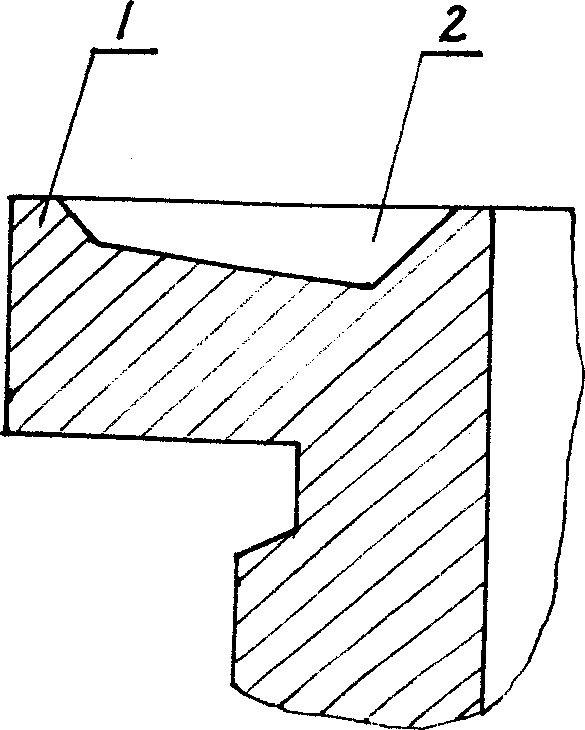

[0022] Example II, such as figure 2 As shown: a gasket groove 2 is provided on the top of the cylinder liner 1, and the gasket groove 2 is an annular slope-shaped groove with a shallow outer mouth and a deep inner mouth (its slope can be determined according to the cylinder wall thickness). In this way, when working, the gasket can be positioned, and the sealing performance is further improved.

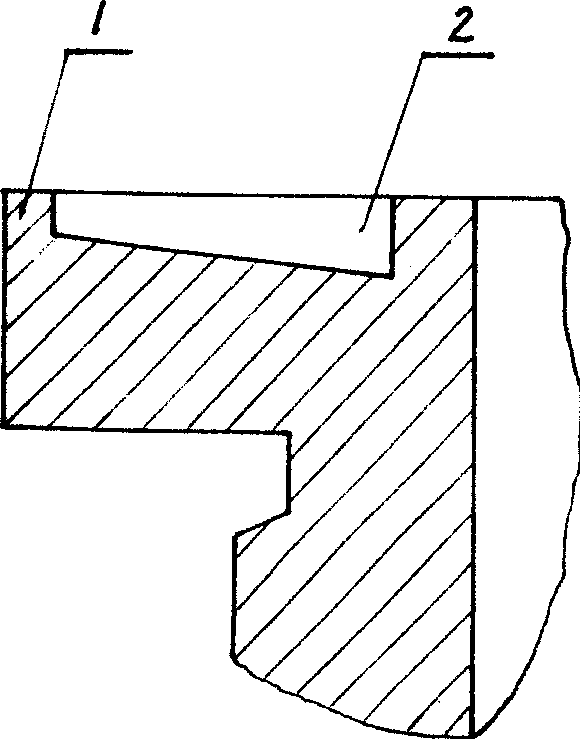

[0023] Embodiment III, such as image 3 As shown: there is a gasket groove 2 on the top of the cylinder liner 1. The gasket groove 2 is an annular slope-shaped groove with a shallow outer opening and a deep inner opening. The side is inclined to form a bell mouth with an upward opening. In this way, when working, because the outside is shallow and the inside is deep, as the pressure in the cylinder continues to rise, the pressure applied to the gasket also increases, and the density of the gasket is smaller on the inside and larger on the outside, and the sealing performance become...

Embodiment V

[0025] Example V, such as Figure 5 As shown: there is a gasket groove 2 on the top of the cylinder liner 1. The gasket groove 2 is an annular slope-shaped groove with a shallow outer opening and a deep inner opening. The side is inclined to be a trumpet mouth with an upward opening, and its inner opening communicates with the inner cavity of the cylinder liner 1, that is, it is an opening inclined toward the inner cavity of the cylinder liner 1 .

[0026] Embodiment VI, such as Figure 6 As shown: there are three tooth-shaped gasket grooves 2 on the top of the cylinder liner 1, that is, on the axial section of the cylinder liner 1, the gasket grooves 2 are in a continuous "W" shape, and the tooth-shaped gaskets The groove 2 is from the outside of the cylinder liner 1 to the inside, and its groove depth is deepened step by step.

[0027] Embodiment VII, such as Figure 7 As shown: the top of the cylinder liner 1 is an inwardly inclined 10° slope, on which five toothed gaske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com