Hydrochloride waste regenerating process for spray roasting

A technology of spray roasting method and hydrochloric acid waste liquid, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of surrounding workshops and environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

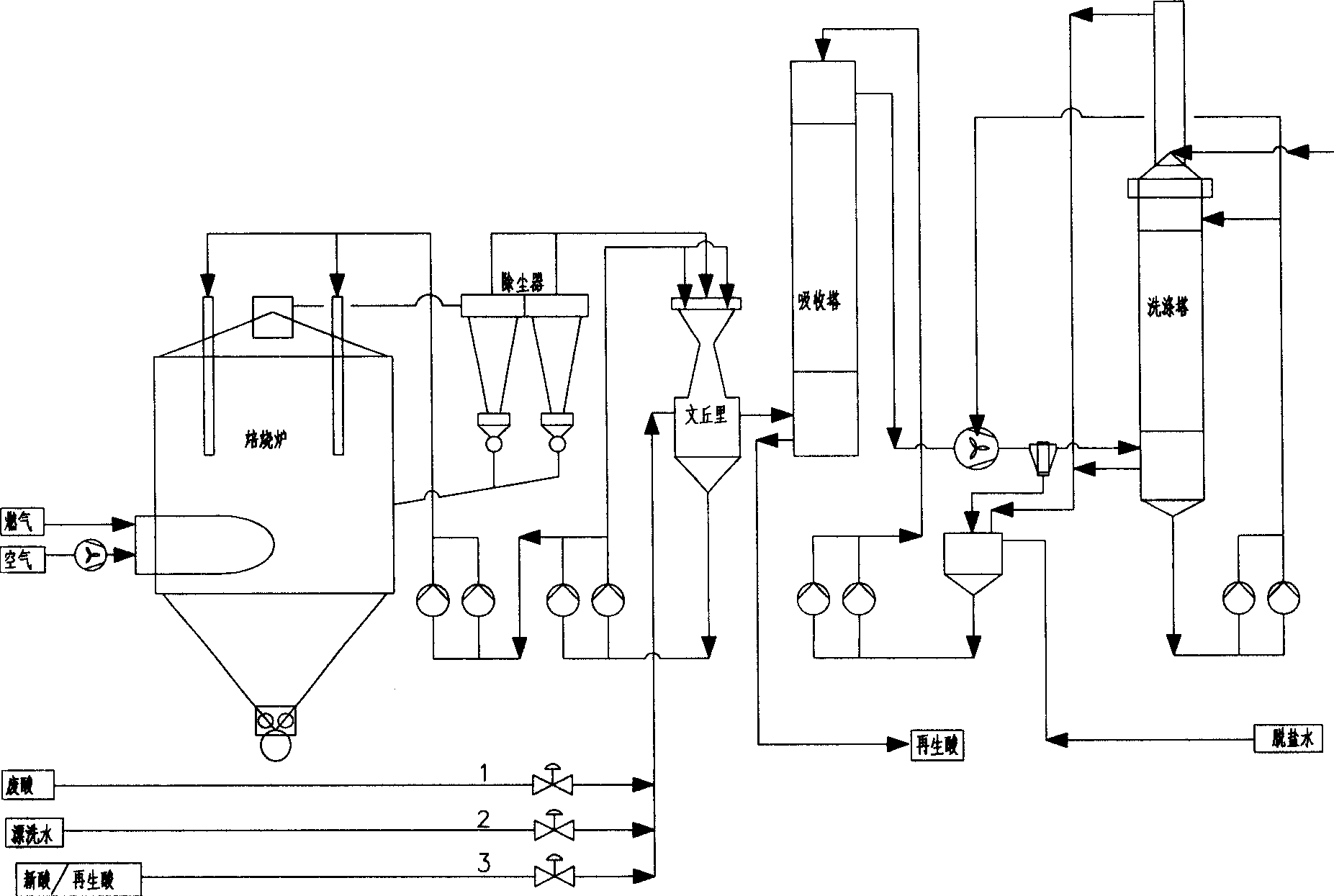

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

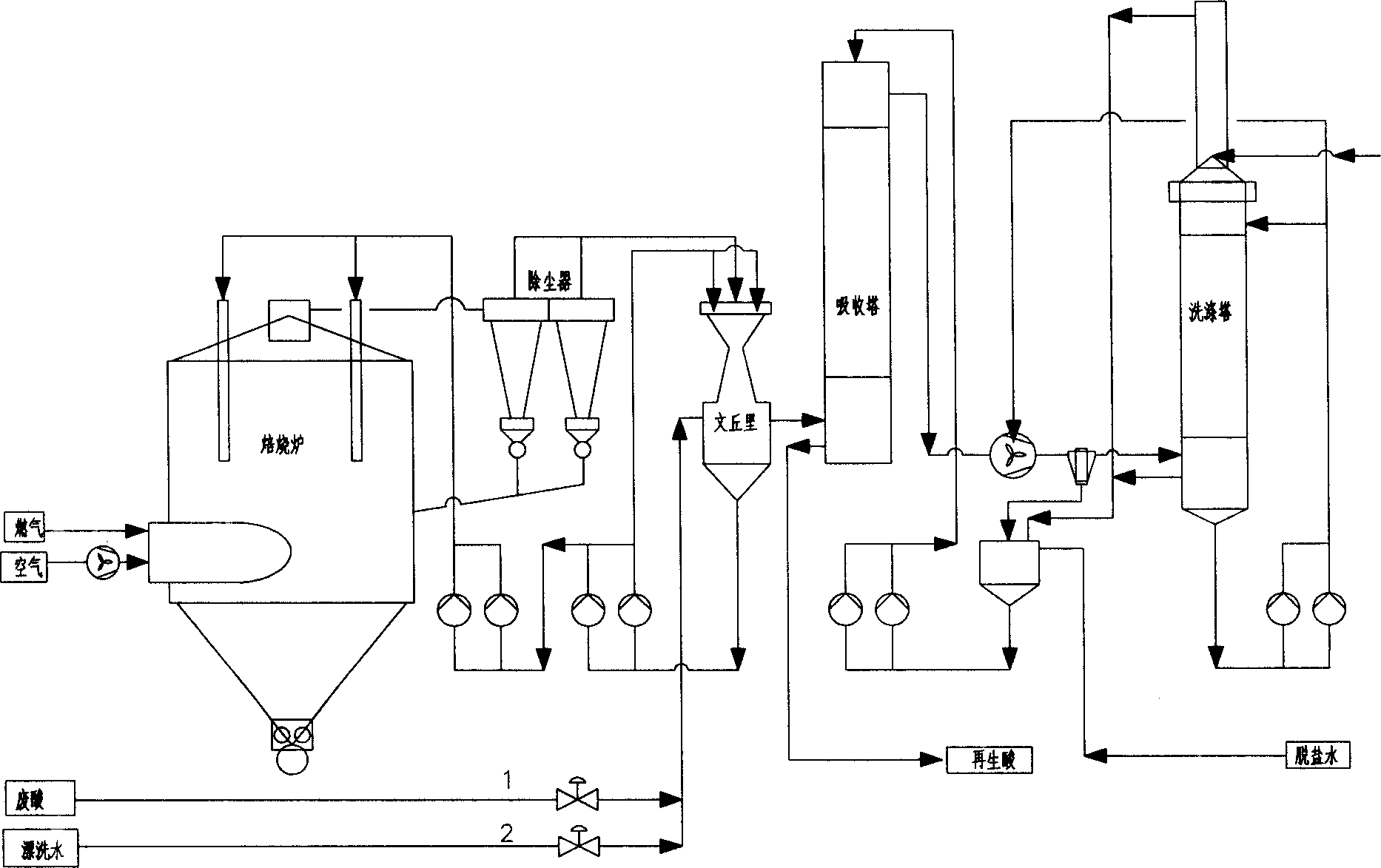

[0015] Such as figure 2 Shown, spray roasting method hydrochloric acid waste liquor regeneration process, it comprises the following steps: 1), water operation: roasting furnace heats up, and after roasting furnace ignites and heats up to furnace top 390 ℃, carries out water operation, and rinsing water enters Venturi pre-concentrator , spray into the roaster through the roaster feed pump for water operation, the temperature, pressure, and flow in the roaster reach the set value and run stably for 8-12 hours; 2), 5-10 minutes before the acid operation, Stop supplying rinsing water to the Venturi pre-concentrator, supply hydrochloric acid (new hydrochloric acid or the regenerated acid of the acid regeneration system) in the Venturi pre-concentrator, and the hydrochloric acid addition is to make the weight concentration of hydrochloric acid in the Venturi pre-concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com