Sheet brake for a press

A technology for brakes and printing presses, which is applied in the directions of sending objects, function instructions, thin material processing, etc., to achieve the effect of high efficiency and enhanced rhythm operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

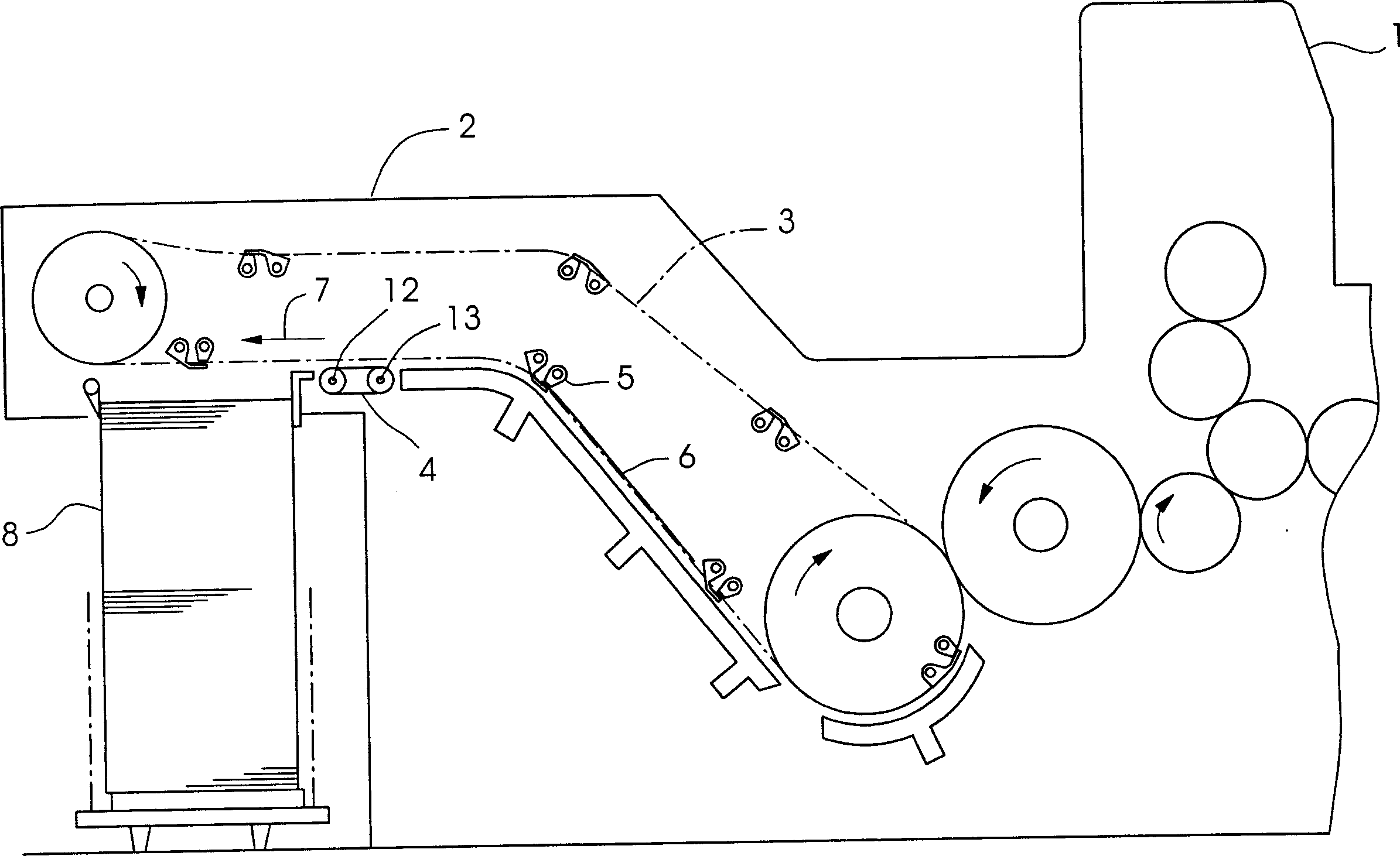

[0018] figure 1 A printing press 1 for perfecting printing is shown. The printing press 1 comprises a delivery 2 with a chain conveyor 3 and a sheet brake 4 arranged below the chain conveyor 3 . The chain conveyor 3 has gripper bridges 5 for securely gripping the leading edge of the printing material sheet 6 . Before the printed product sheet 6 is deposited on the delivery pile 8 , the sheet brake 4 brakes the printed product sheet 6 and in this case tensions the printed product sheet 6 transversely to the sheet travel direction 7 .

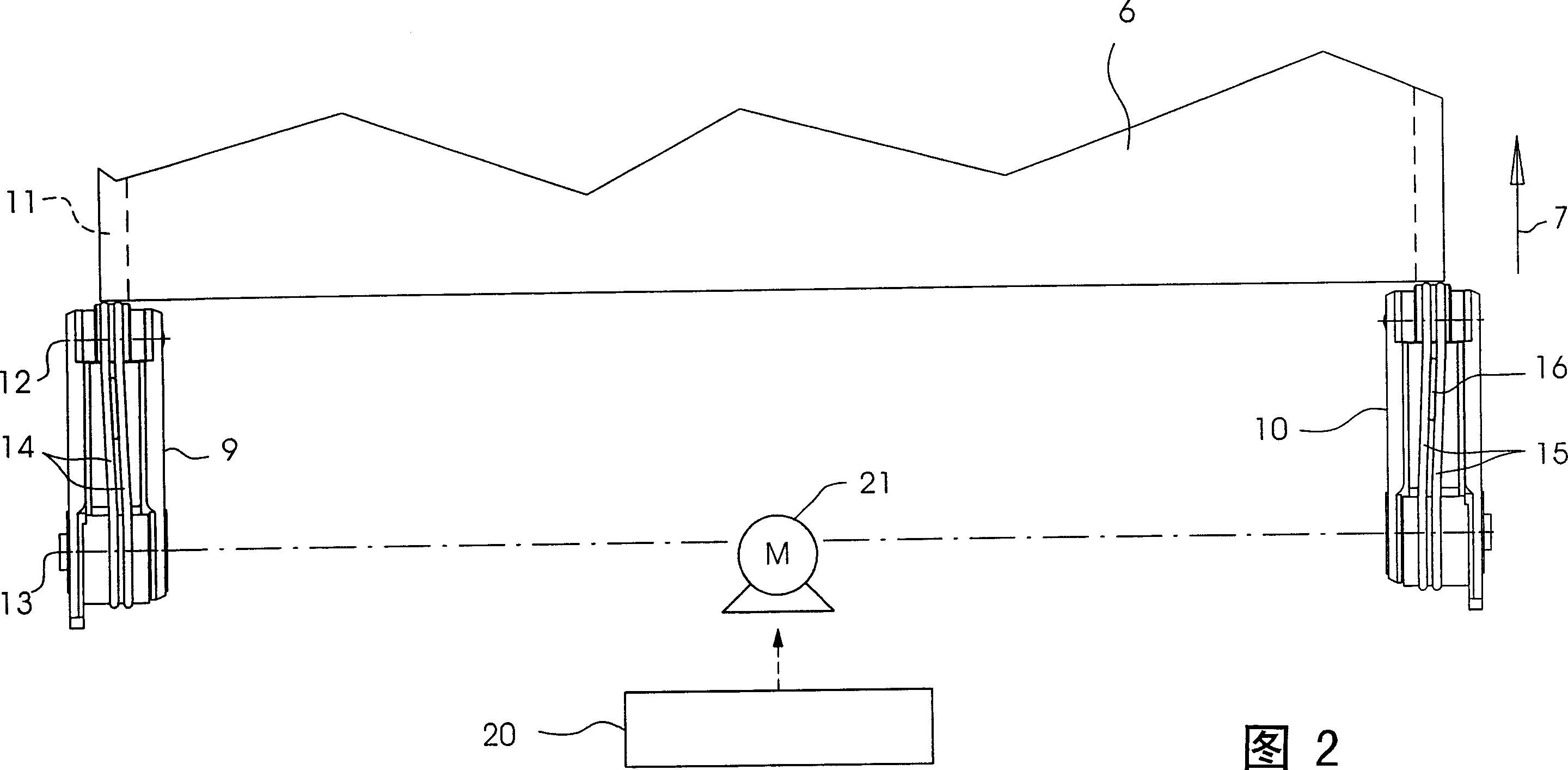

[0019] FIG. 2 shows that the sheet brake 4 only includes a first brake assembly 9 and a second brake assembly 10 and does not include other brake assemblies. During braking and lateral tensioning, the first braking assembly 9 is in contact with a side edge 11 of the substrate sheet 6 without printed images, while the second braking assembly 10 is in contact with the other side edge. Between the two brake assemblies 9 , 10 the printing materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com