Wheel bearing apparatus having wireless sensor

A wireless sensor and bearing device technology, applied in bearing assembly, rotating bearings, bearings, etc., can solve the problems of power supply efficiency reduction, power supply efficiency reduction, fuel consumption reduction, etc., to achieve improved spatial freedom and good efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

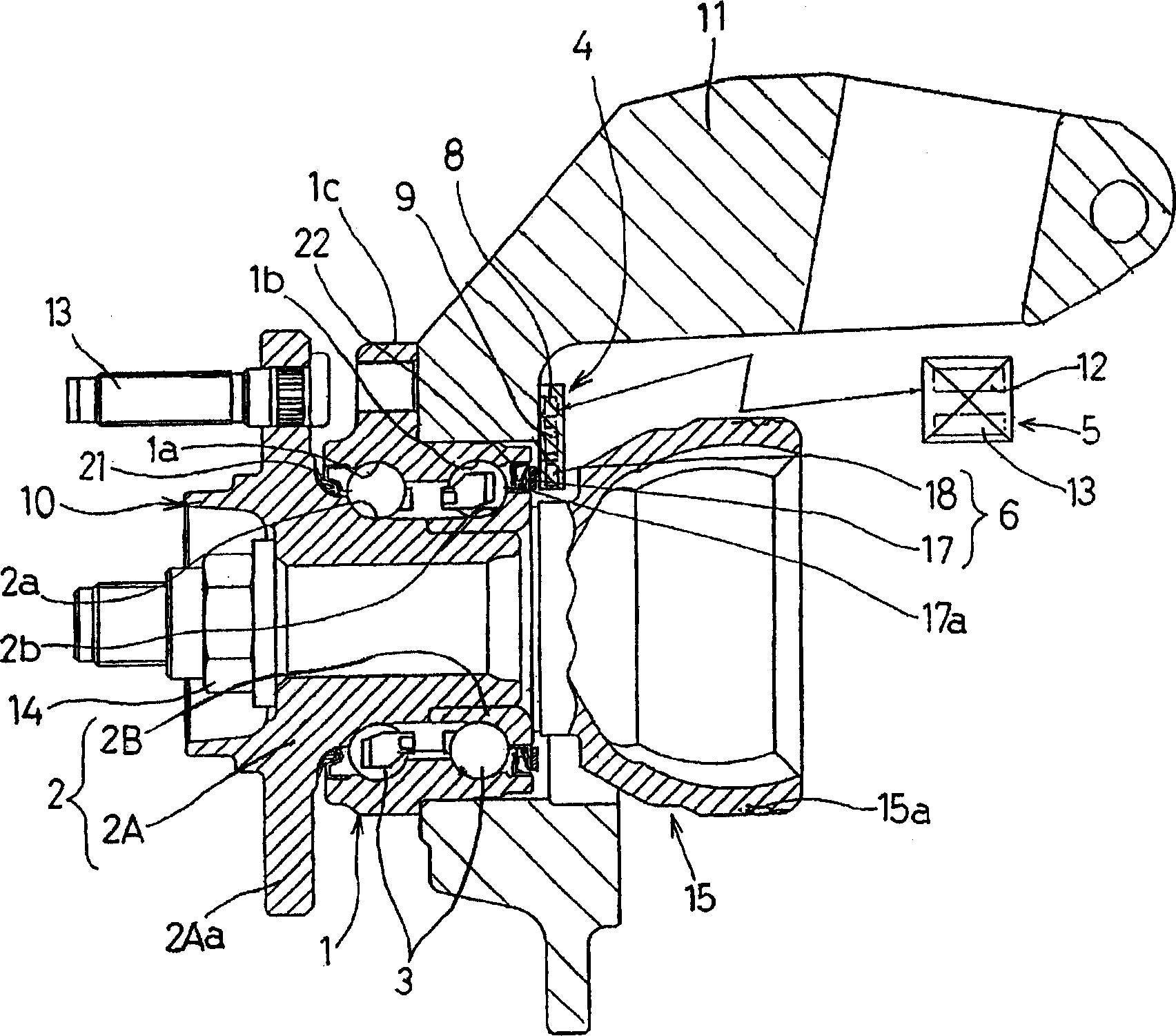

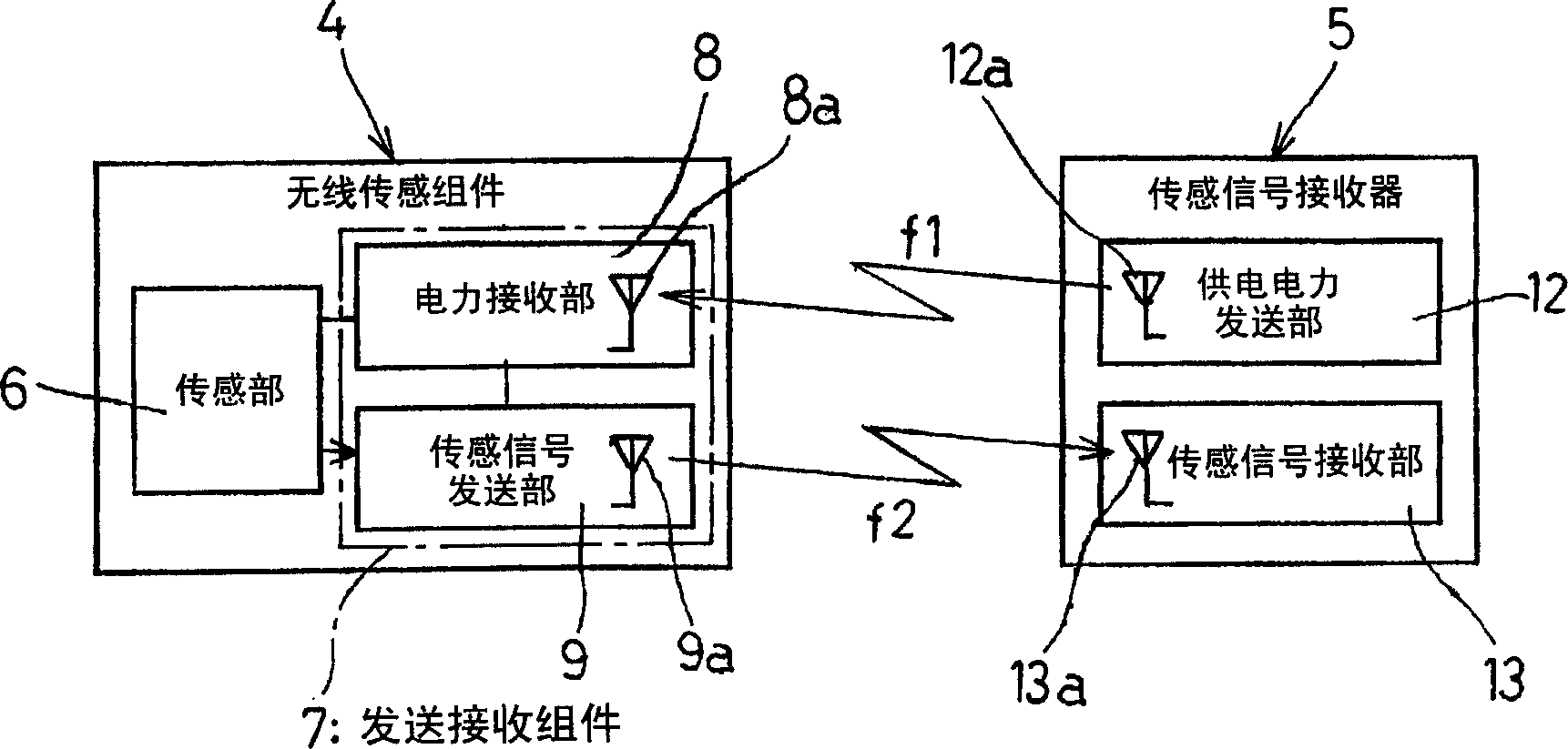

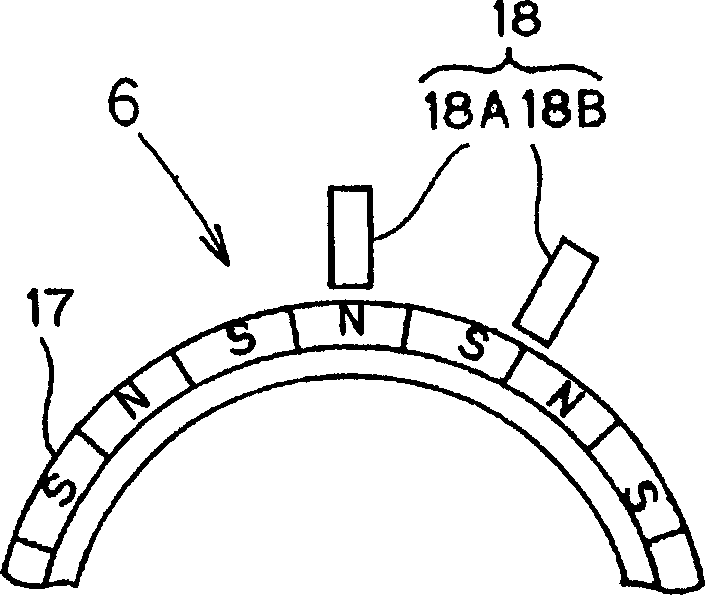

[0025] The following is based on figure 1 ~ Fig. 3, describe the first embodiment of the present invention. The bearing device 10 for a wheel with a wireless sensor includes an outer part 1 having a plurality of rows of track surfaces 1a, 1b on the inner periphery of the outer part 1; The track surfaces 2a, 2b of the rows of track surfaces 1a, 1b; multiple rows of rolling bodies 3, the multiple rows of rolling bodies 3 are interposed between the facing track surfaces 1a, 2a, 1b, 2b, and the wheel bearing device 10 is The wheels are supported on the vehicle body in a rotatable manner. Both axial ends of the bearing space between the outer member 1 and the inner member 2 are sealed by seal members 21 , 22 . A flange 1 c is provided on the outer periphery of the outer member 1 , and the outer member 1 is attached to the vehicle body via a knuckle 11 . The knuckle 11 is fitted to the outer periphery of the inner end of the outer member 1, and the fitted portion is attached to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com