Membrane electrode assembly (MEA), methode for its manufacturing and a method for preparing a membrane to be assembled in a mea

A membrane electrode assembly and electrode layer technology, applied in the direction of electrical components, circuits, fuel cells, etc., can solve problems such as no mention of pretreatment or preadjustment, ambiguity, etc.

Inactive Publication Date: 2006-11-01

PAUL SCHERRER INSTITUT

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But, unfortunately, S. Srinivasan et al. are completely silent on pretreatment or preconditioning of membranes prior to hot press

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of grafting | aaaaa | aaaaa |

Login to View More

Abstract

A method for preparing a membrane to be assembled in a membrane,electrode assembly is disclosed comprising the step of swelling an ion-conducting membrane in a liquid containing at least one solvent or to an atmosphere containing the vapor phase of at least one solvent by controlling the content of the solvent in the ion conducting membrane. Further, a method for manufacturing a membrane electrode assembly using a ion conducting membrane is disclosed, comprising the steps of: providing a ion conducting membrane in a pre-swollen state; coating of the ion conducting membrane on both sides with an electrode layer to form a sandwich; and hot-pressing the sandwich to form an ion conducting bonding of the afore-mentioned layers of the sandwich. Furthermore, a membrane electrode assembly is disclosed comprising a hot pressed sandwich comprising an electrode layer, a ion conducting membrane and again an electrode layer, thereby using the ion conducting membrane in its pre-swollen status prior to the hot-pressing.

Description

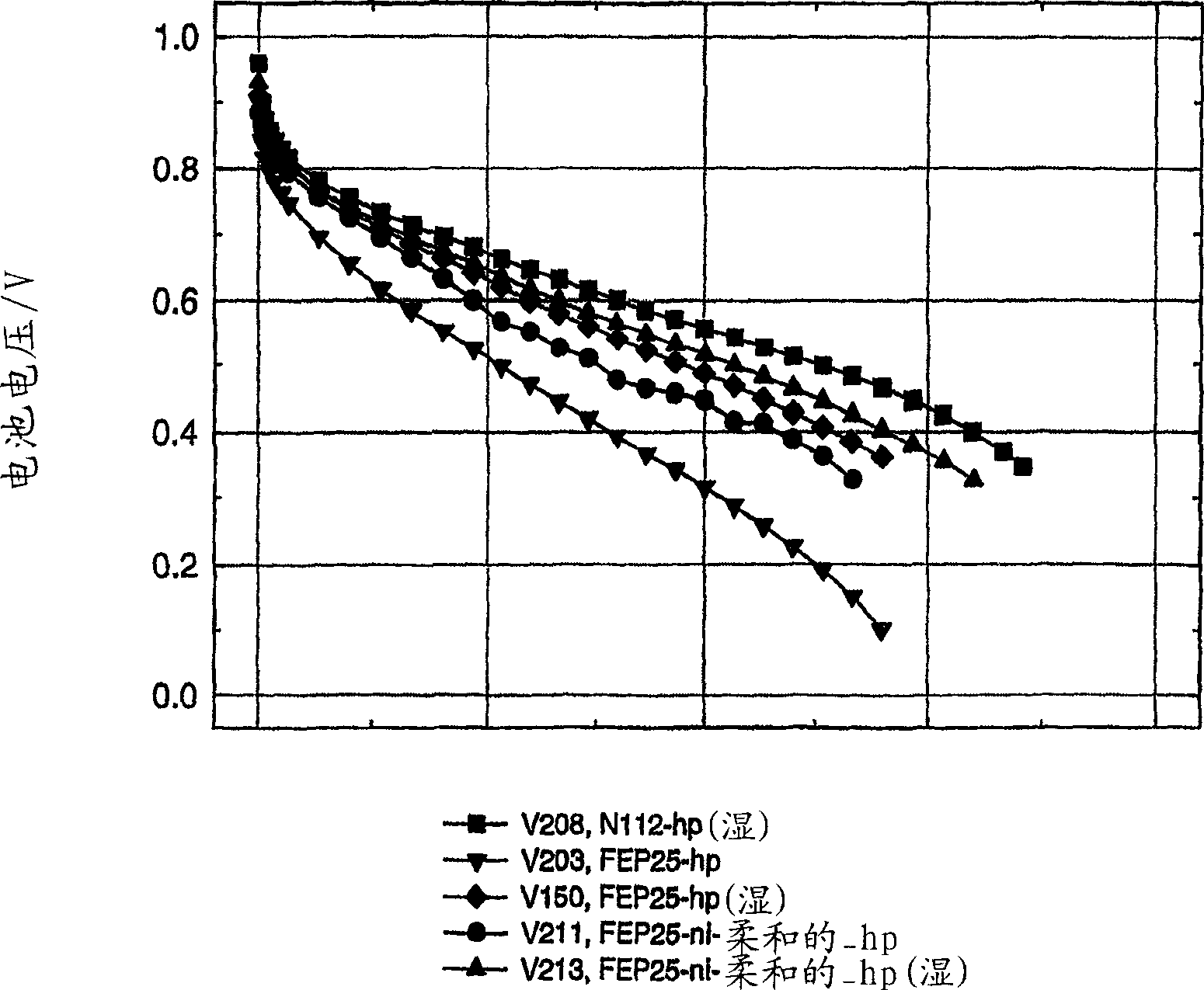

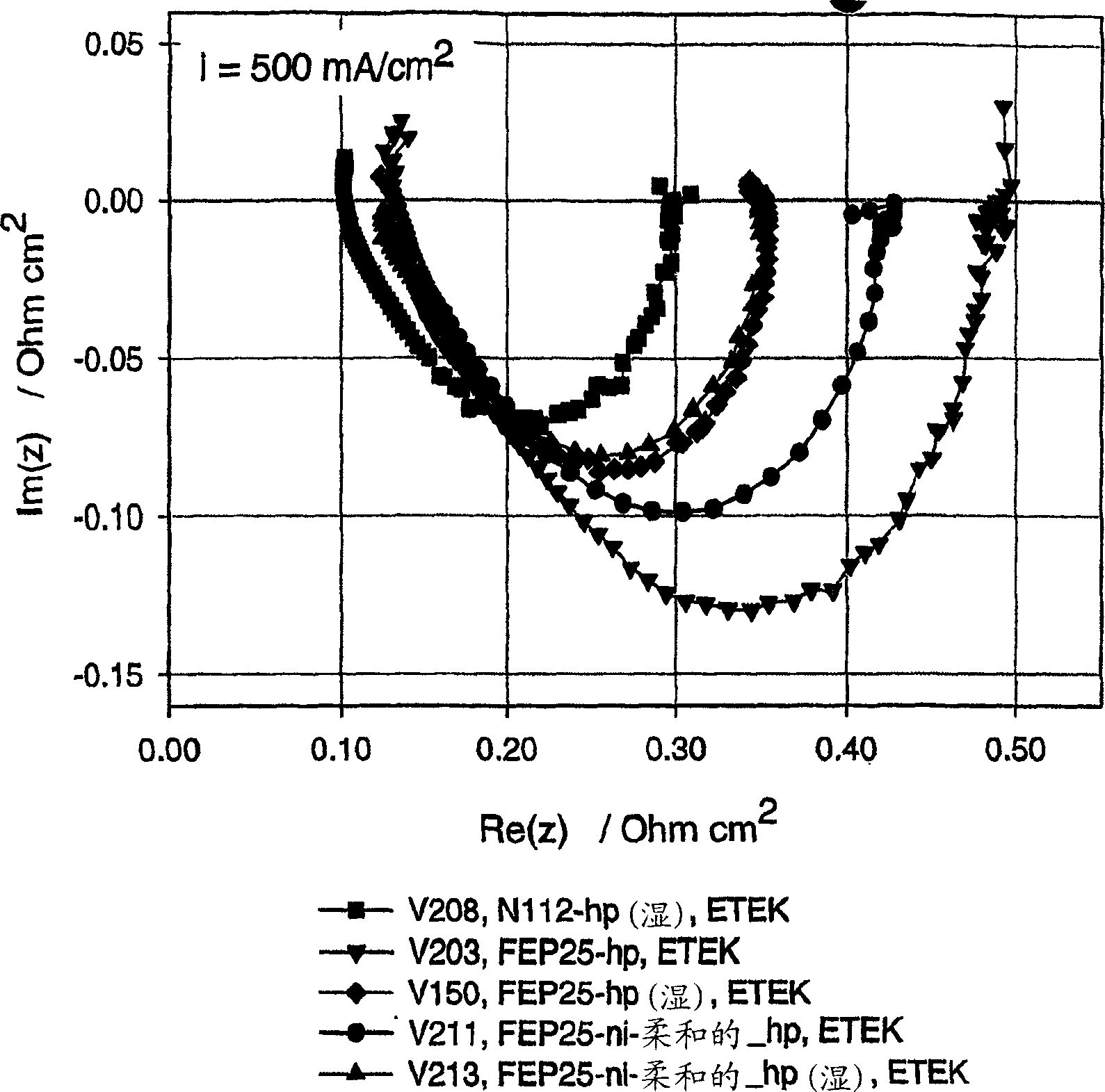

technical field [0001] The present invention relates to a method of making a membrane electrode assembly and a method of making a membrane to be assembled into a membrane electrode assembly. Furthermore, the present invention relates to membrane electrode assemblies. Background technique [0002] There is a need for fast and simple methods of fabricating membrane electrode assemblies (MEAs) with optimized interfaces. As discussed by Huslage et al. [J. Huslage, T. Rager, B. Schnyder and A. Tsukada, "Radiation-grafted membrane / electrode assemblies with improved interface", Electrochim. Acta 48 (2002) 247-254], the preparation of this and Optimizing the interface of radiation-grafted crosslinked films is an unresolved problem in this field. Specifically, they note that suboptimal electrochemical interface formation is characterized by unstable fuel cell performance, long runs to achieve steady-state performance, and poor adhesion between the membrane and electrodes even after...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M8/0234H01M8/10H01M8/1086

CPCY02E60/50Y02P70/50

Inventor H·-P·布拉克G·G·谢勒尔L·古布勒

Owner PAUL SCHERRER INSTITUT

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com