Pen with propulsive refill

A telescopic, refill technology, applied to ink pens, pen holders, ball-point pens, etc. with an ink storage tube in the pen holder, can solve the problems of difficulty in meeting consumers' demands for innovation and changes, different operation methods, and inability to interoperate, etc. Conducive to large-scale production, prolong use time, and improve the effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

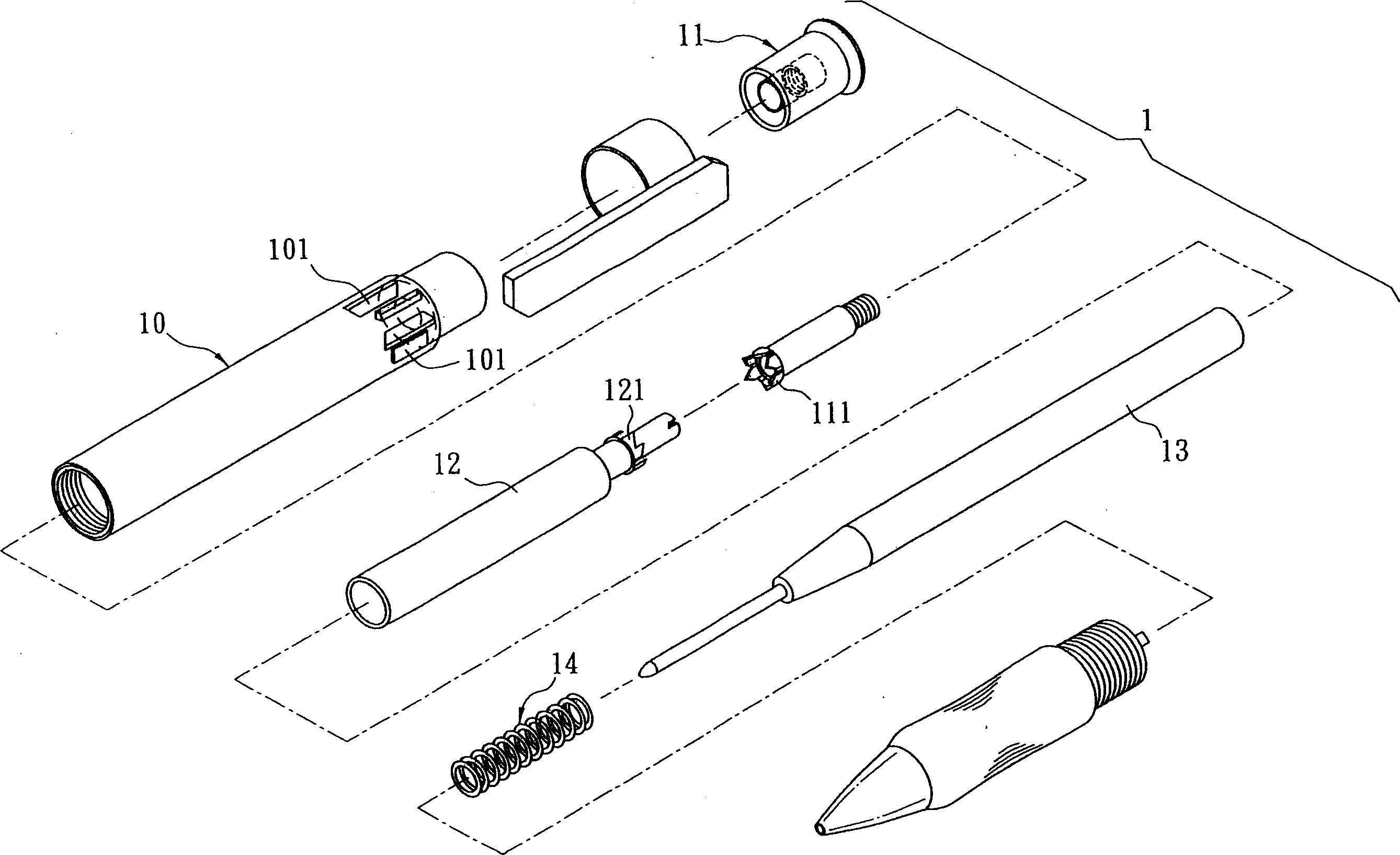

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] Referring to Figures 5 to 8, the retractable pen 2 of the present invention is similar in appearance to the general push-type pen 1, but the known general push-type pen 1 can only press the button to control the expansion and contraction of the refill, while the present invention In addition to pressing the button to control the expansion and contraction of the pen core, the push-type pen 2 can also be swung forward to control the expansion and contraction of the pen core. This embodiment specifically includes an outer pen tube 20, a button 30, an inner sleeve 40, and The inner pen core 50 and the return spring 60 of the casing 40, the outer pen tube 20 is screwed to a front tube 23, and the outer pen tube 20 is provided with a central hole 22, and the inside of the tail end of the outer pen tube 20 is provided with several rings arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com