Method for continuous casting of concrete in liquid storage structure

A technology of liquid storage structure and pouring method, which is applied in building structures, public buildings, gymnasiums, etc., can solve the problems of high technical requirements and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

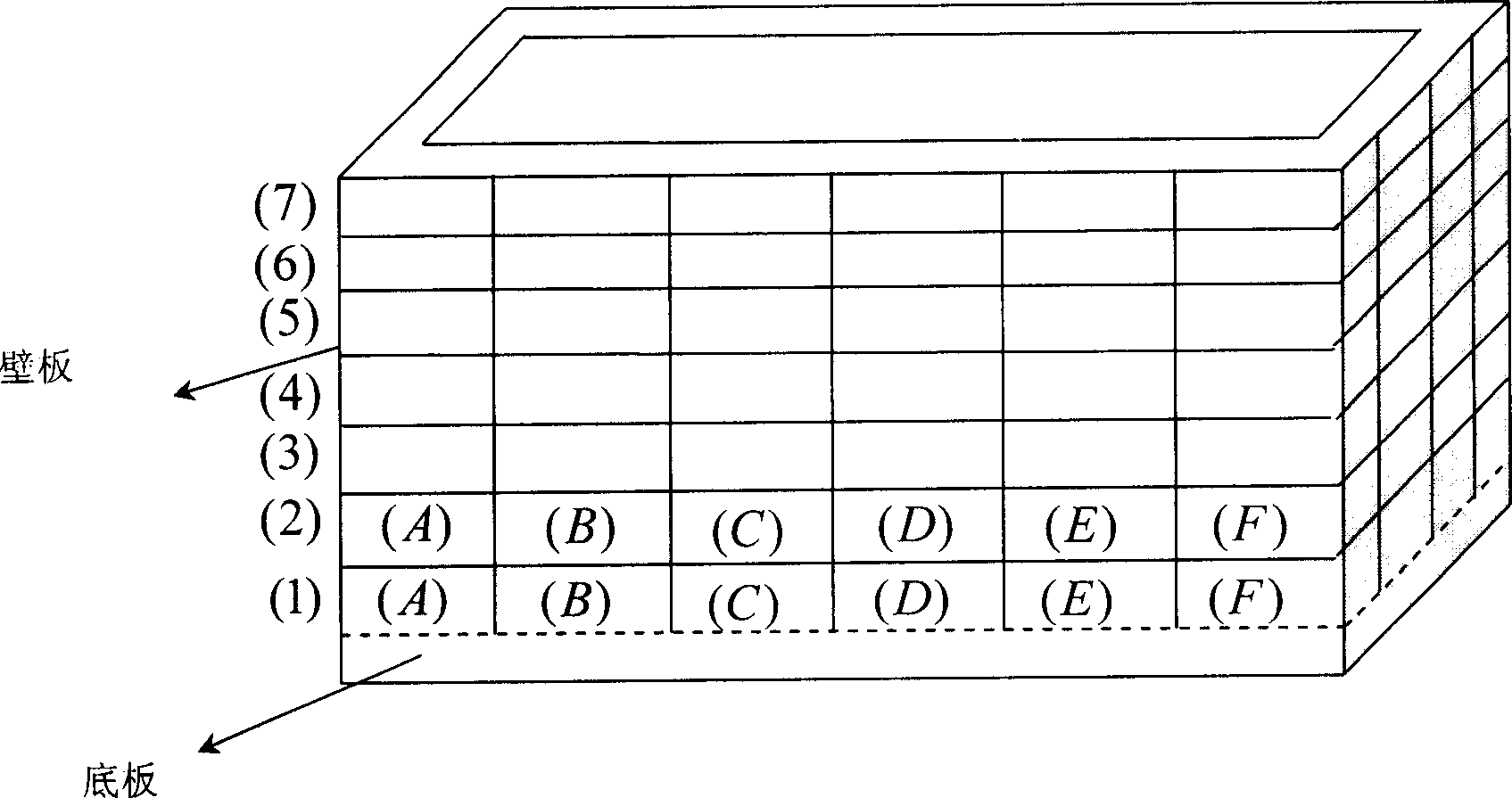

[0012] figure 1 Middle (1), (2), (3), (4), (5), (6), (7)... represent the construction layer; (A), (B), (C), (D), (E), (F)...represent the construction section.

[0013] Such as figure 1 Shown, the present invention divides construction layer and construction section according to setting time and strength of concrete,

[0014] 1. The height of the construction layers (1), (2), (3), (4), (5), (6), (7) and other construction layers is equal to the thickness of the wall board.

[0015] 2. In order to facilitate construction and ensure the continuity of pouring, divide the construction sections (A), (B), (C), (D), (E), (F) and other construction sections according to the time specified in Table 1.

[0016] 3. Bind the bottom plate and wall steel bars at the same time.

[0017] 4. Complete the construction of wall panels and floor formwork.

[0018] 5. After pouring the bottom slab concrete, pour the concrete layered and segmented evenly and symmetrically around the wall slab....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com