Fiber-optic grating sensor and fiber-optic grating detection device having same

A fiber grating and sensor technology, which is applied in the direction of measuring devices, using optical devices to transmit sensing components, instruments, etc., can solve the problems of small tuning range, inability to meet larger capacity multi-point detection, low resolution, etc., to improve the use of Power frequency voltage, solve the high voltage creepage problem, and improve the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

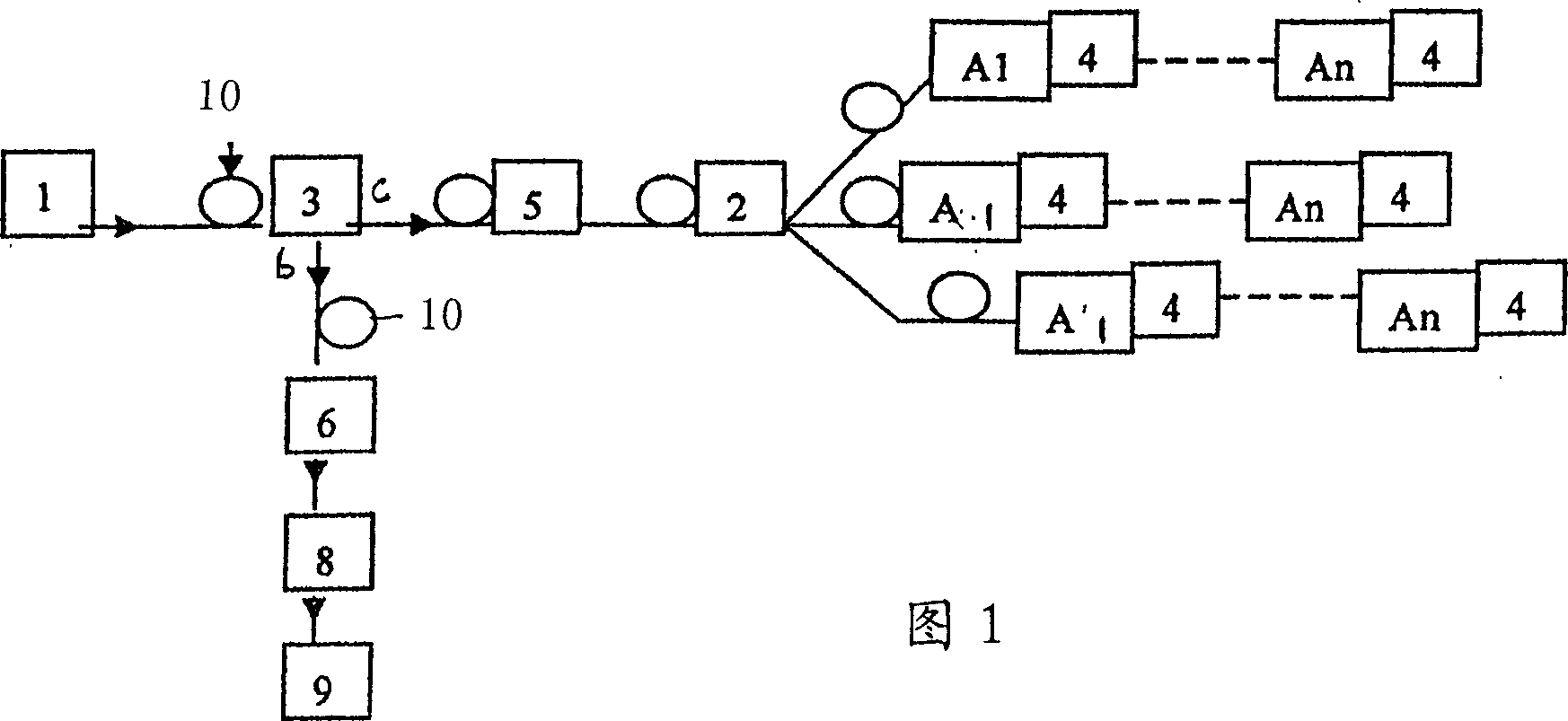

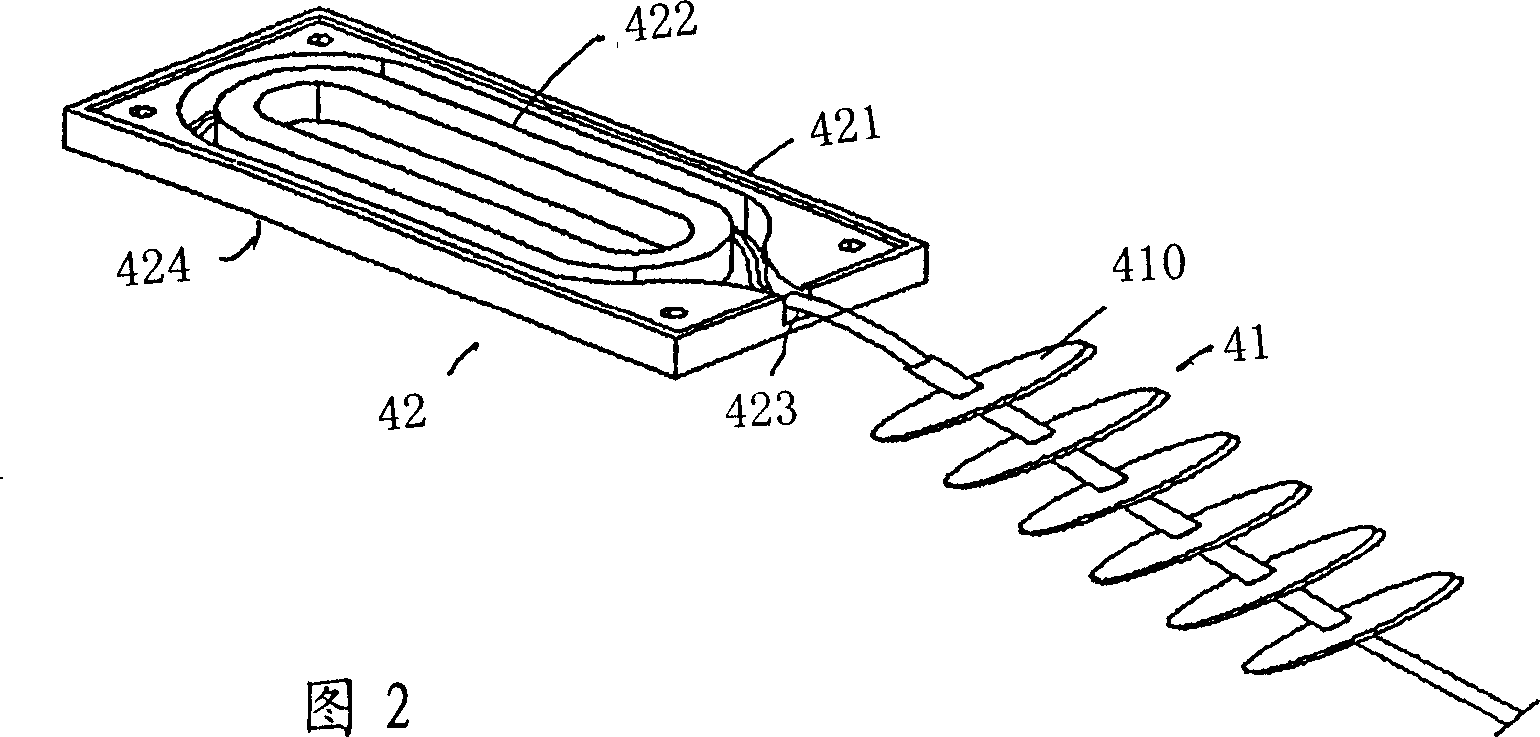

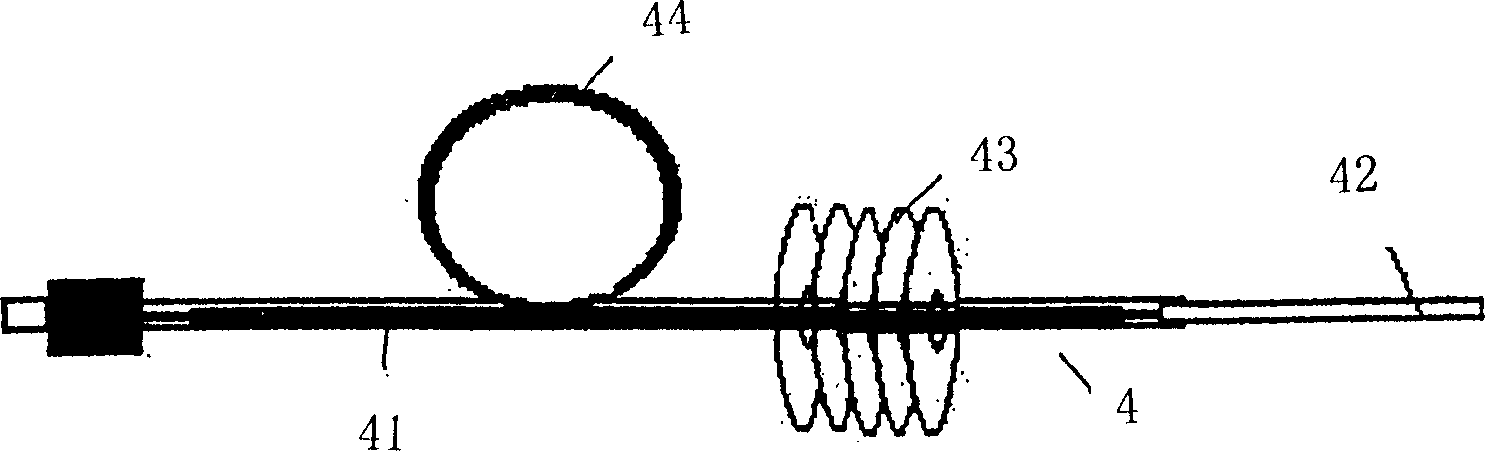

[0047] A large-capacity fiber grating temperature measuring device as shown in Figure 1-6, wherein,

[0048] An optical coupler or optical circulator 3, its first branch port is connected with broadband light source 1 through optical fiber 10; Its second branch port c is connected with standard fiber grating 5 through optical fiber;

[0049] The standard optical fiber grating 5 is connected to the common end of a 1×n optical switch 2, the branch port of the optical switch 2 is connected to each measurement channel, and each measurement channel is provided with a sensor group An, which is controlled by a preset The wavelength code is composed of 1-n fiber grating sensors 4 connected in series with different central wavelengths; thus, when a change in a certain reflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com