Bolt-nut mechanism

A technology of bolts, nuts and bolts, applied in the directions of nuts, bolts, screws, etc., can solve the problems of inability to achieve lightweight, troublesome grounding connection, etc., and achieve the effect of simple grounding connection, ensuring the action range, and the large action range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

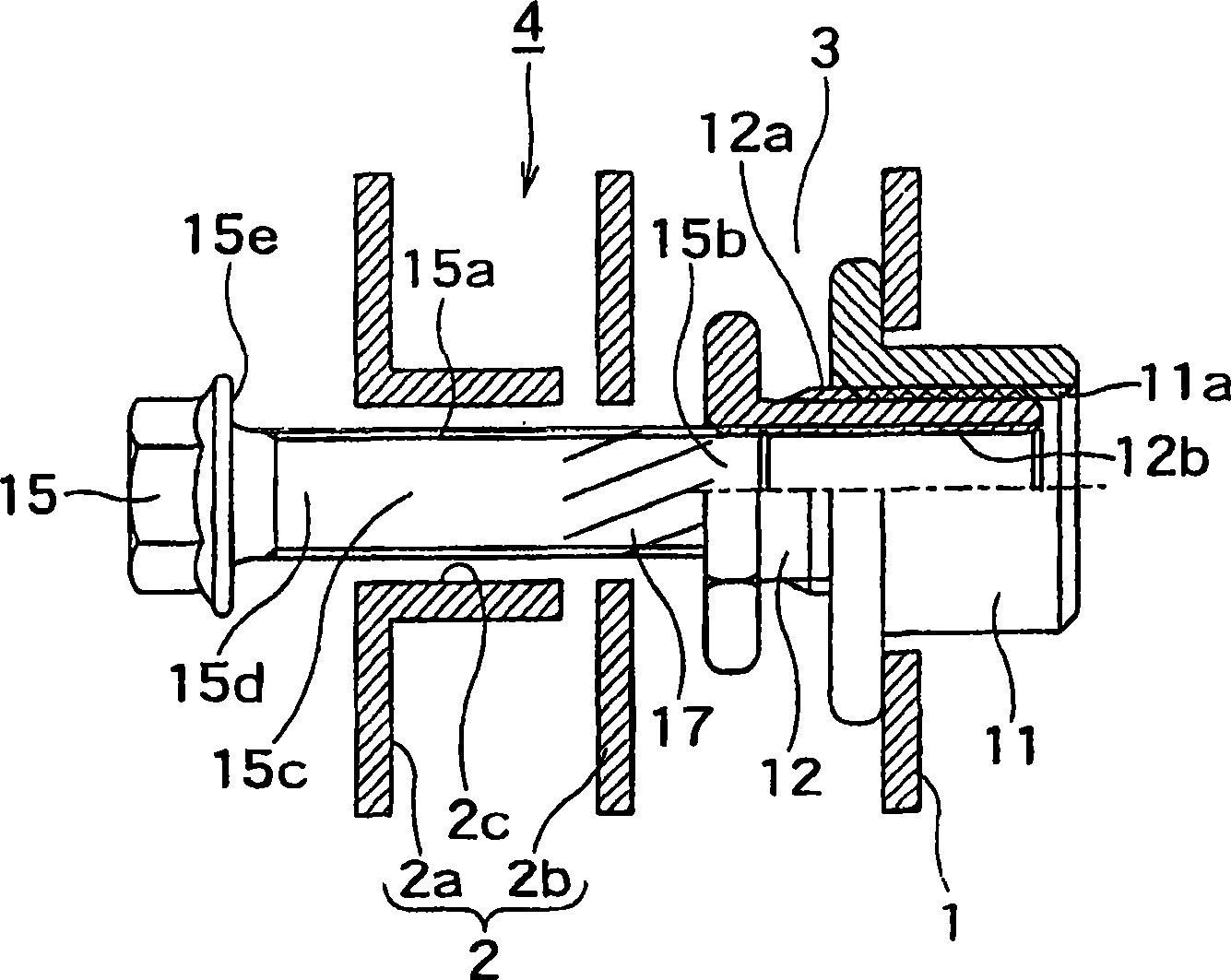

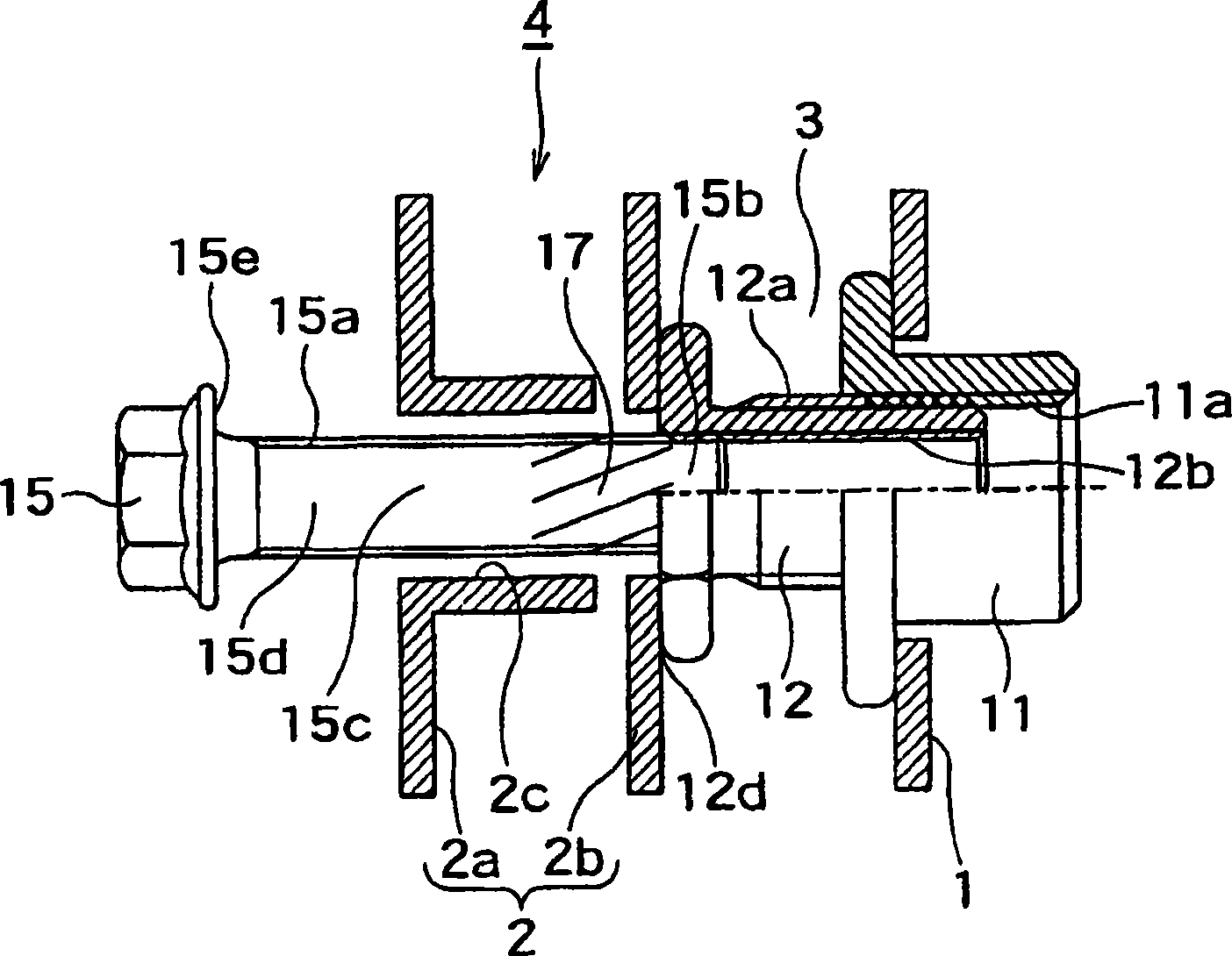

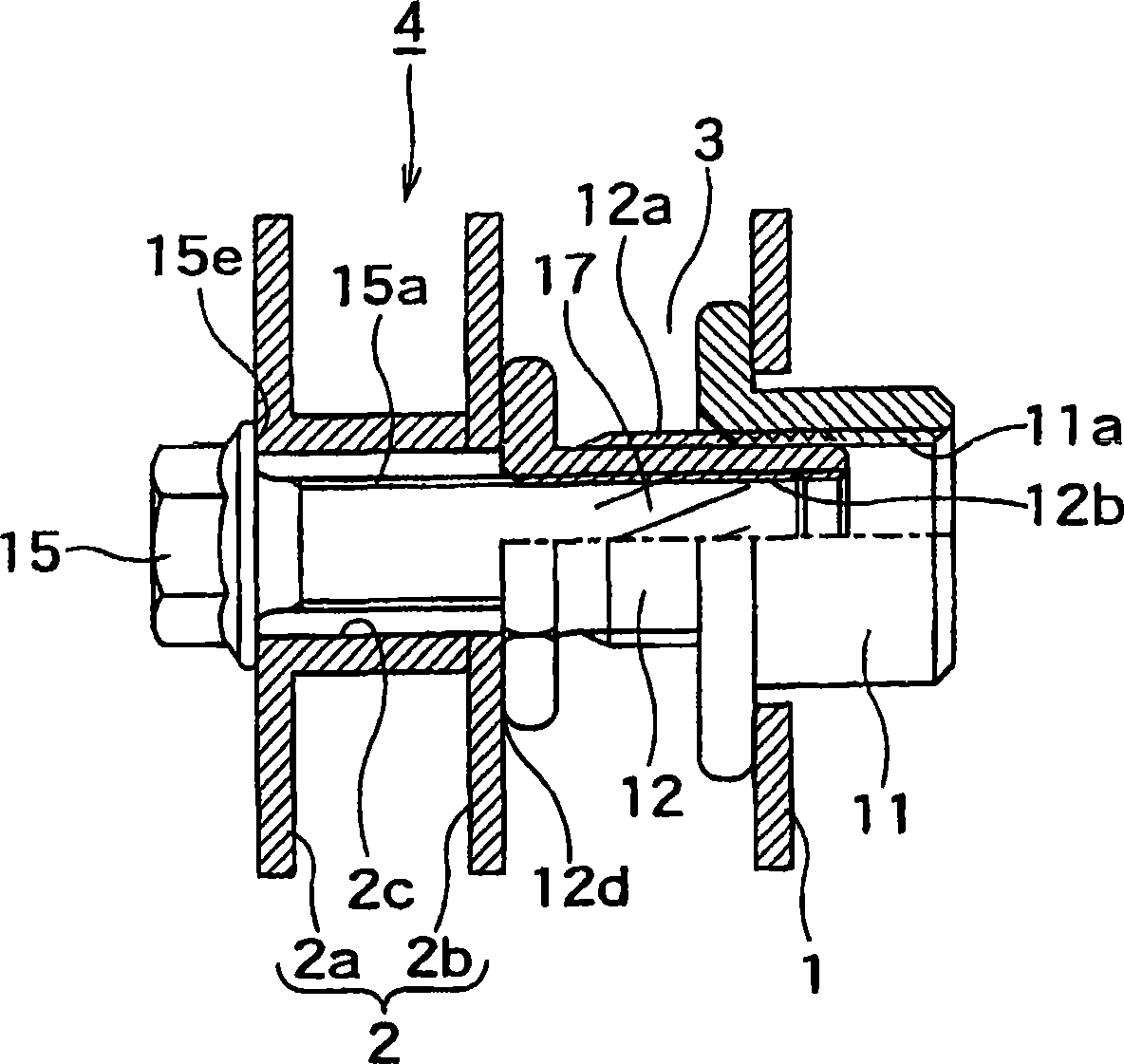

[0051] Hereinafter, embodiments of the bolt and nut mechanism of the present invention will be described with reference to the drawings.

[0052] exist figure 1 2 shows a bolt and nut mechanism 4 for attaching the steering member 1 to the vehicle frame 2 so as to absorb a gap (interval) 3 existing between the steering member 1 and the vehicle frame 2 as an assembly. The vehicle frame 2 includes an outer panel 2 a and an inner panel 2 b, and an insertion hole 2 c is formed in the vehicle frame 2 .

[0053] The bolt-nut mechanism 4 has a nut 11 previously fixed to the steering member 1 by welding, a bush 13 for absorbing the gap 3, and a bolt 15 inserted into the insertion hole 2c.

[0054] Before the steering member 1 is mounted on the vehicle frame 2, the bush 12 is assembled on the nut 11 in advance. The bolts 15 are inserted from the side of the outer plate 2a, and the outer plate 2a, the inner plate 2b, and the steering member 1 are attached at the same time. A gap 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com