High-precision radio frequency soft tag

A high-precision, labeling technology, which is applied in the direction of record carriers used in machines, instruments, computer components, etc., can solve the problems of unfavorable capacitance area capacity, wire inductance, etc., to reduce the label area, increase capacity, and increase the number of coils Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

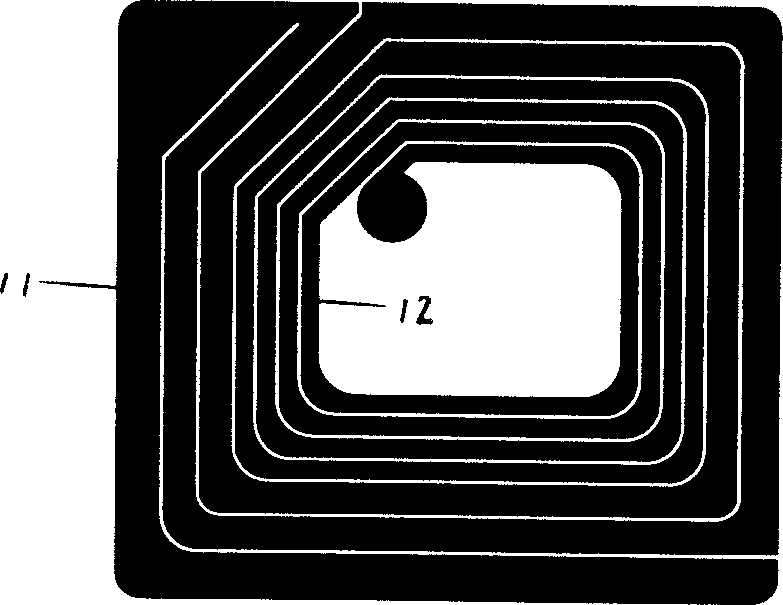

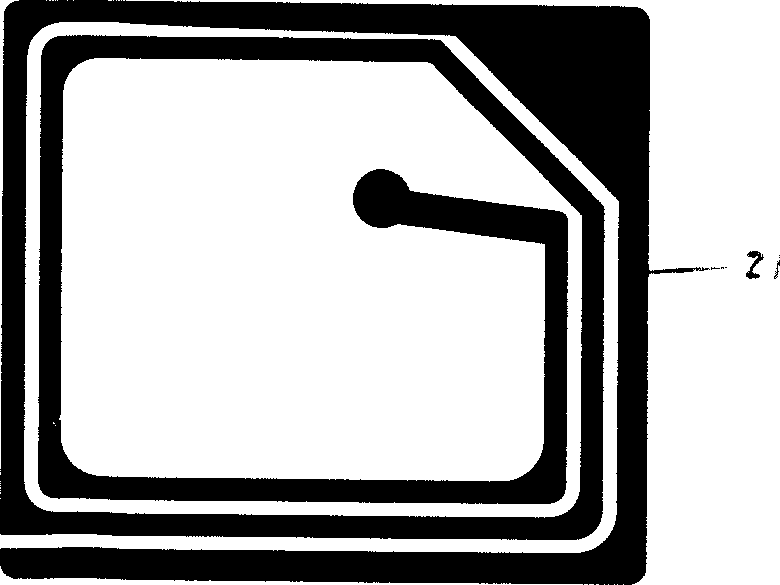

[0027] A high-precision radio frequency soft label. The base layer of the label is composed of an insulating film layer and conductive layers respectively attached to the first surface and the second surface of the insulating film layer. The conductive layer is equipped with capacitors, wires and decoding A decoding circuit composed of dots, the capacitor is located on the periphery of the coil composed of wires, and the width of the capacitor wire and the coil wire gradually decreases from the outside to the inside. The insulating film layer and the conductive layer together constitute the base layer of the label, and a hard insulating material layer is arranged on the base layer. The hard material layer has a pre-processed breaking mark, and the breaking mark has an intersection angle with the circuit on the conductive layer.

[0028] The structure of Example 2 is based on Example 1 with a snap-off non-revivable structure added. After the label is used, the label can be brok...

Embodiment 3

[0034] A high-precision radio frequency soft label, the base layer of the label is composed of an insulating film layer and conductive layers respectively attached on the first surface and the second surface of the insulating film layer. The insulating film layer is a polyethylene film layer with a thickness of 0.015±0.001mm. The conductive layer has a decoding circuit composed of capacitors, coil wires and decoding points. The capacitor is located at the periphery of the coil composed of wires. The widths of the capacitor wires and the coil wires gradually decrease from outside to inside. The width of the back capacitor wires No larger than the positive capacitance lead. Both the front conductive layer and the back conductive layer of the label have capacitor wires and coil wires, thereby forming a soft label with double-sided circuits. Through this structure, the inductance of the coil part can be further increased, and the precision of the product can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com