A flat seaming method for making seamless appearance clothes

A wireless and clothing technology, which is applied in the direction of sewing tools, etc., can solve the problems of easy fluffing of the cut, low cutting positioning accuracy, easy cutting deviation, etc., to improve waterproof performance, avoid water permeability, and increase aesthetics sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

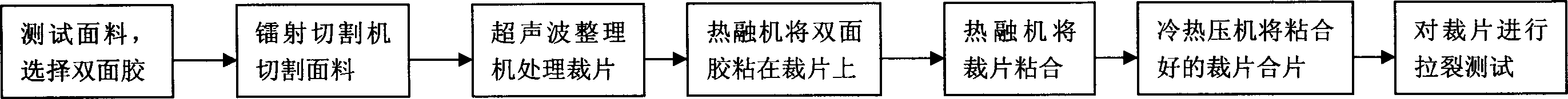

[0015] see figure 1 Shown, a kind of seaming method of clothing traceless, its steps are as follows:

[0016] A. Test the performance of the fabric, choose hot-stick double-sided tape;

[0017] B. Use a laser cutting machine to cut the fabric to ensure the cutting accuracy of the cut pieces;

[0018] C. Use an ultrasonic finishing machine to process the edges of the cut pieces. The frequency of the ultrasonic finishing machine is 50,000 Hz, and the speed is 3 yards per minute to ensure that the edges of the cutting pieces are not fluffed;

[0019] D. Use a heat-melting machine to stick the double-sided adhesive tape on the cut piece. The pressure of the heat-melting machine is set at 4 kg, the temperature is set at 320°C, and the speed is set at 3 yards per minute;

[0020] E. Then use the hot melt machine to glue the cut pieces with the double-sided tape, the pressure is set at 4 kg, the temperature is set at 318°C, and the speed is set at 3 yards per minute;

[0021] F. C...

Embodiment 2

[0024] see figure 1 Shown, a kind of seaming method of clothing traceless, its steps are as follows:

[0025] A. Test the performance of the fabric, choose hot-stick double-sided tape;

[0026] B. Use a laser cutting machine to cut the fabric to ensure the cutting accuracy of the cut pieces;

[0027] C. Process the edges of the trimmed pieces with an ultrasonic finishing machine. The frequency of the ultrasonic finishing machine is 50,000 Hz and the speed is 4 yards per minute to ensure that the edges of the cutting pieces are not fluffed;

[0028] D. Use a heat-melting machine to stick the double-sided adhesive tape on the cut piece. The pressure of the heat-melting machine is set at 6 kg, the temperature is set at 480°C, and the speed is set at 4 yards per minute;

[0029] E. Then use a hot melt machine to glue the cut pieces with double-sided adhesive strips, set the pressure at 6 kg, set the temperature at 322°C, and set the speed at 4 yards per minute;

[0030] F. Comb...

Embodiment 3

[0033] see figure 1 Shown, a kind of seaming method of clothing traceless, its steps are as follows:

[0034] A. Test the performance of the fabric, choose hot-stick double-sided tape;

[0035] B. Use a laser cutting machine to cut the fabric to ensure the cutting accuracy of the cut pieces;

[0036] C. Use an ultrasonic finishing machine to process the edges of the cut pieces. The frequency of the ultrasonic finishing machine is 50,000 Hz and the speed is 3.5 yards per minute to ensure that the edges of the pieces are not fluffed;

[0037] D. Use a heat-melting machine to stick the double-sided adhesive tape on the cut piece. The pressure of the heat-melting machine is set at 5 kg, the temperature is set at 400°C, and the speed is set at 3.5 yards per minute;

[0038] E. Then use the hot melt machine to glue the cut pieces with double-sided adhesive strips, set the pressure at 5 kg, set the temperature at 320°C, and set the speed at 3.5 yards per minute;

[0039] F. Combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com