Device and method for controlling robot

一种控制装置、机械手的技术,应用在机械手、计算机控制、程序控制机械手等方向,能够解决机械手的作业程序相关性受损等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail below with reference to the drawings. In the drawings, the same or similar structural elements are given common reference signs.

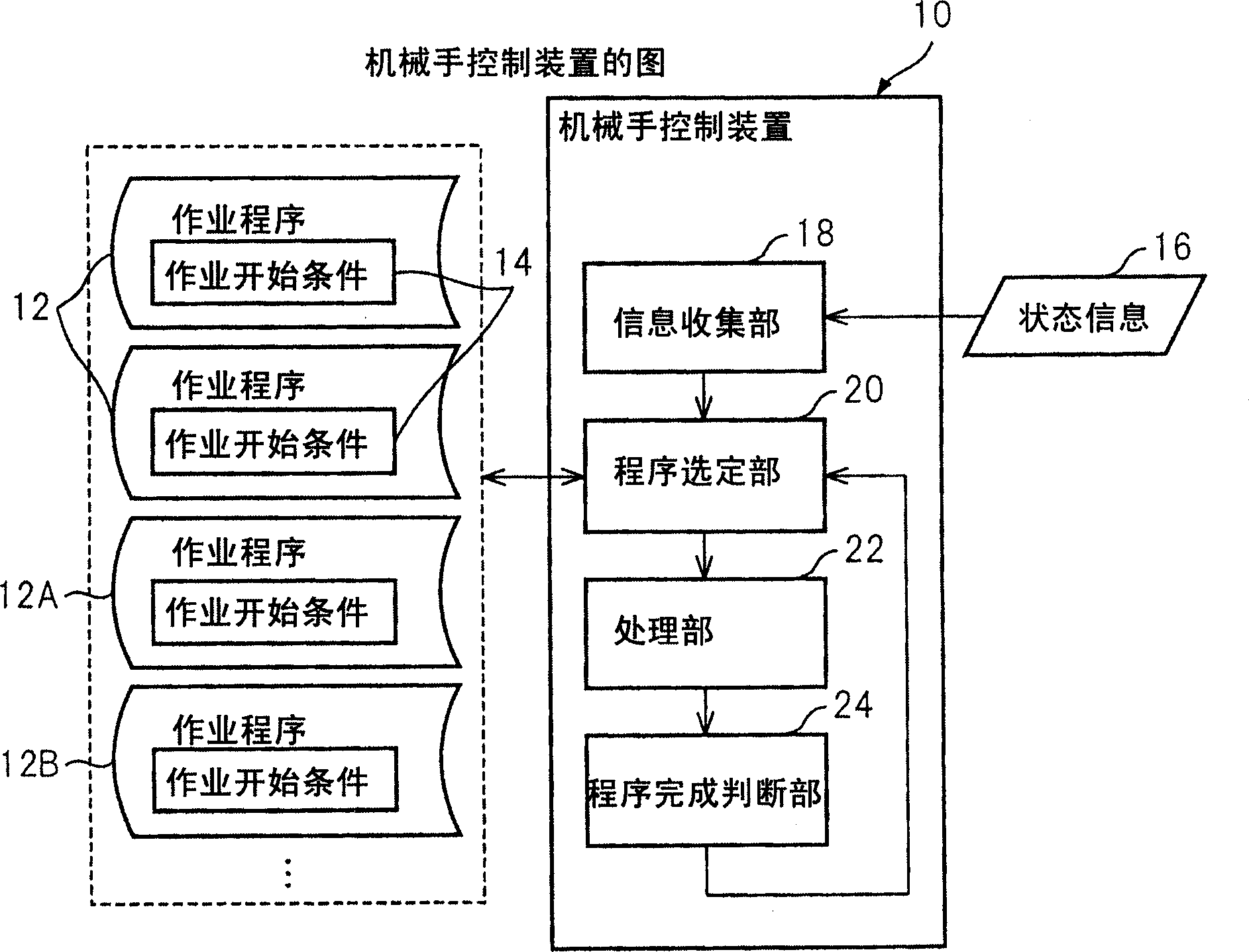

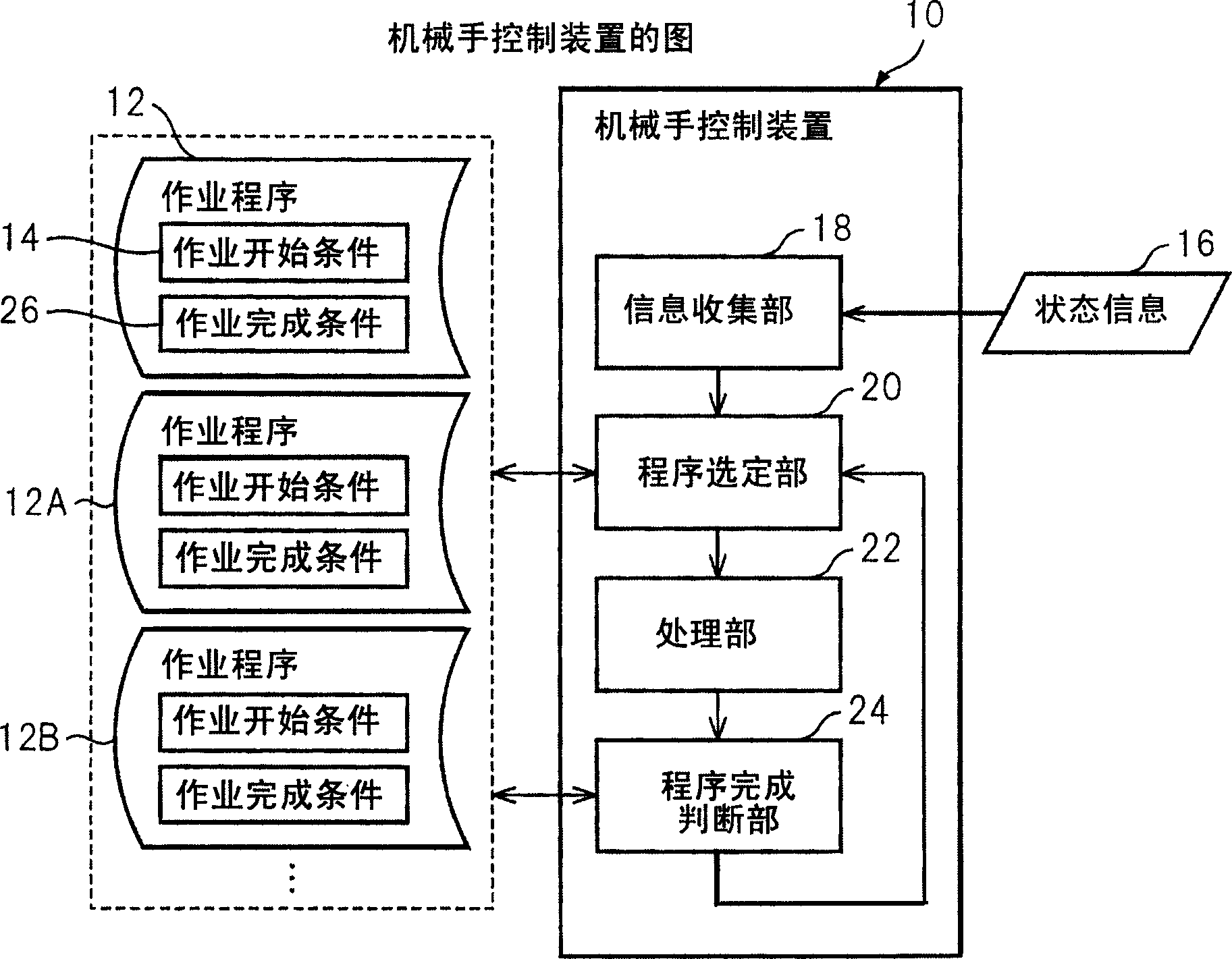

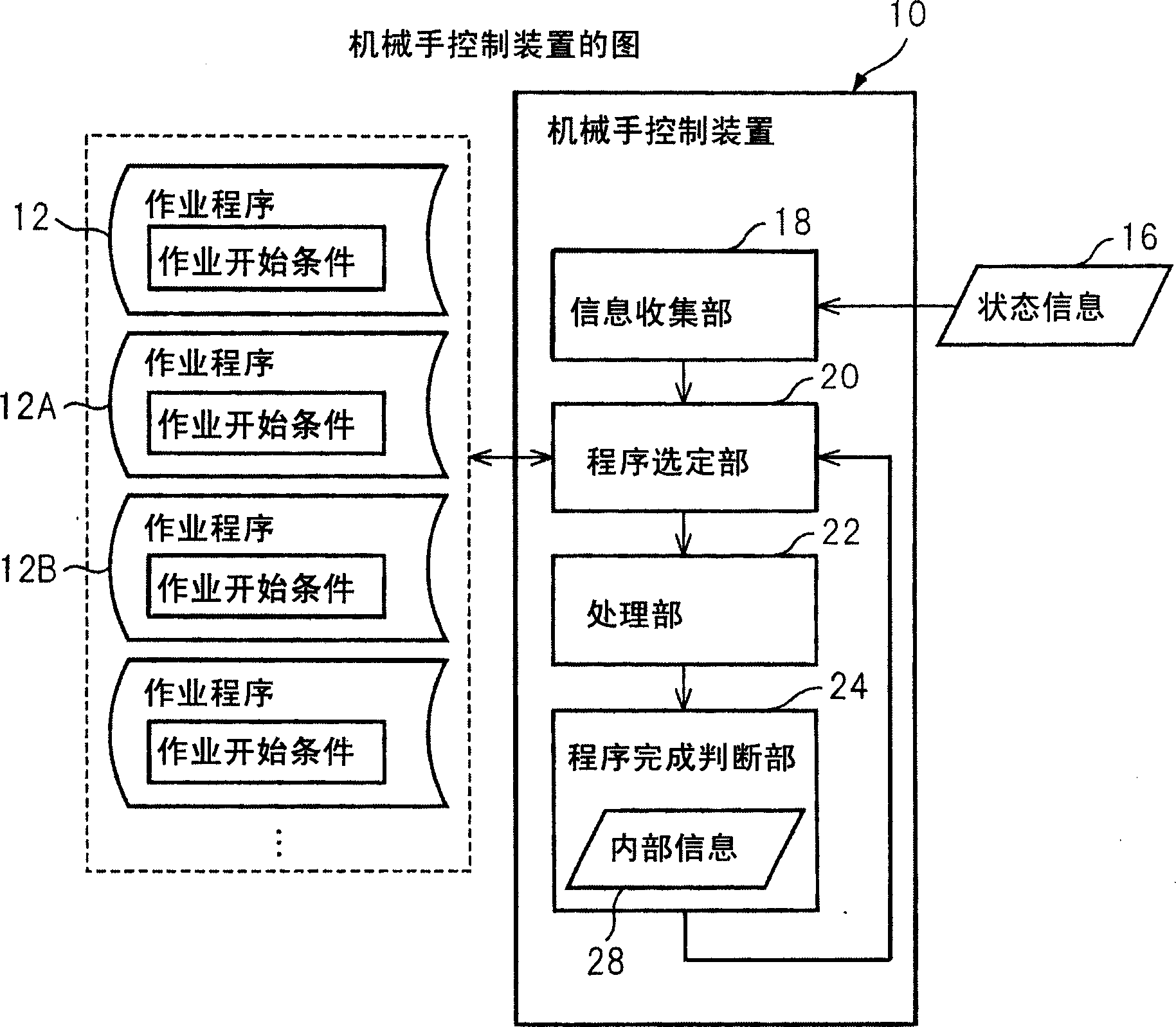

[0037] With reference to the accompanying drawings, figure 1 The basic structure of the robot control device 10 of the present invention is shown in a functional block diagram. The robot control device 10 causes the manipulator to execute operations including a plurality of work units in parallel with respect to a plurality of workpieces in accordance with a plurality of work programs 12 that respectively instruct a plurality of work units. Here, each of the plurality of work programs 12 includes descriptions of work start conditions on the premise that the robot starts the corresponding work unit. The manipulator control device 10 has an information collection unit 18 that collects state information 16 that indicates the state of the environment in which the manipulator perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com