Transferring drawing baking lacquer panel and its production method

A production method and panel technology are applied in the field of baking varnish decorative panels to achieve the effects of simple production method, more beautiful colors and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

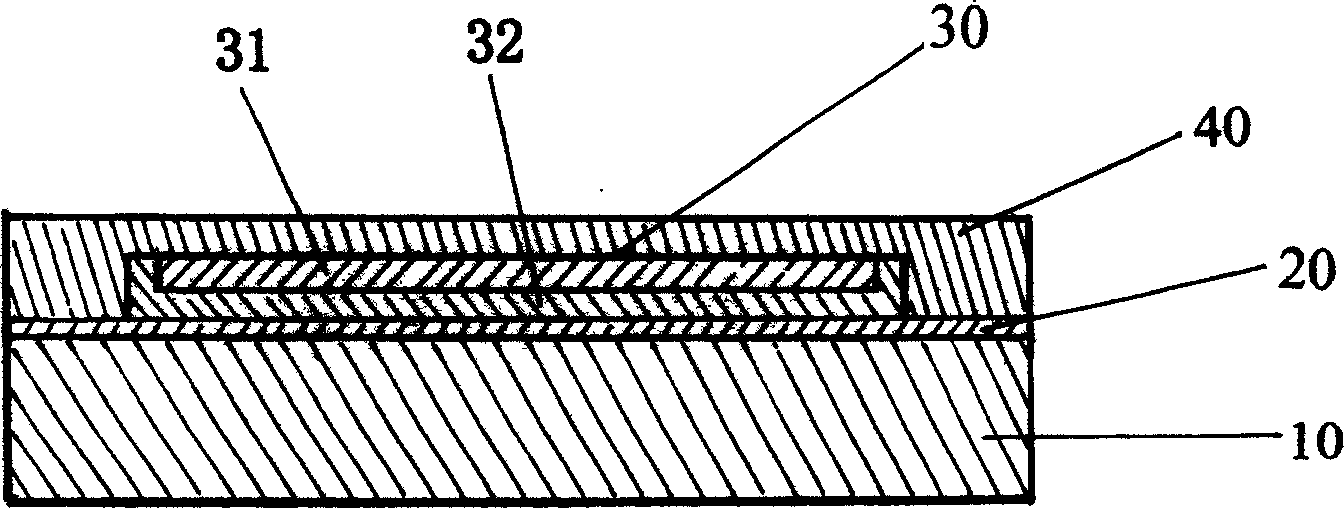

[0026] like figure 1 As shown, it is a schematic cross-sectional structure diagram of the present invention. The paint-moving paint panel includes a substrate 10, wherein the substrate 10 is a medium density board, and the substrate 10 is covered with a layer of polyester primer and then covered with a layer of polyester color surface. Paint 20, on which a water transfer painting 30 is set, the water transfer painting 30 includes an ink painting layer 31 and an epoxy resin layer 32, and finally covers a layer of polyester varnish 40, and the painting baking varnish panel can be used to make furniture and cabinets , showcase or wall decoration panels.

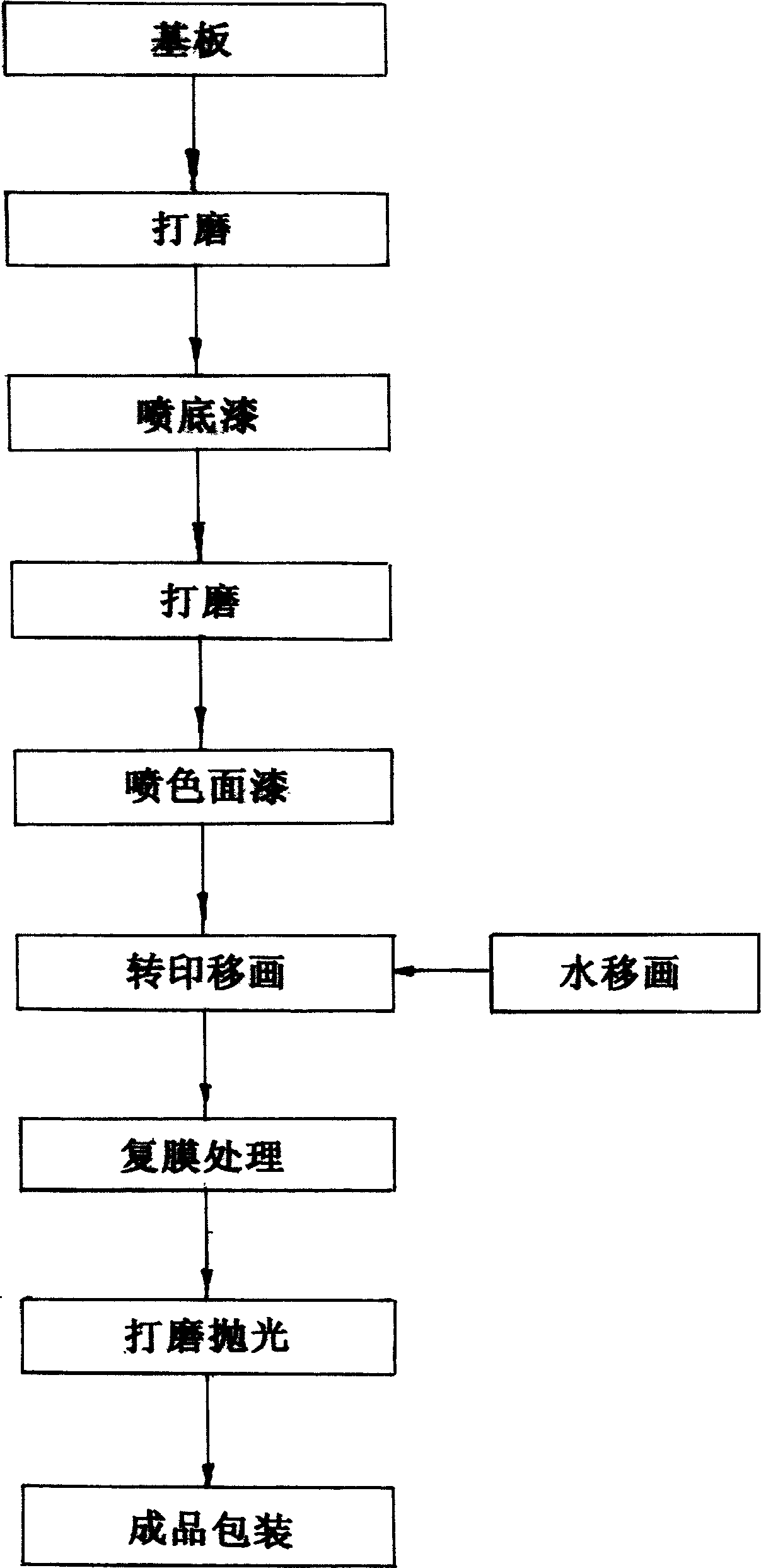

[0027] like figure 2 As shown, it is the production process flow chart of the present invention, and the production process flow of this paint-moving baking varnish panel is:

[0028] (1) The substrate is polished, the substrate is a medium-density wooden board, and the substrate is polished with 240 # ~320 # Dry sandpaper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com