Internal combustion engine

An internal combustion engine and cylinder technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of complex internal combustion engine structure and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below with the help of Figure 1 to Figure 10 The present invention is described in detail.

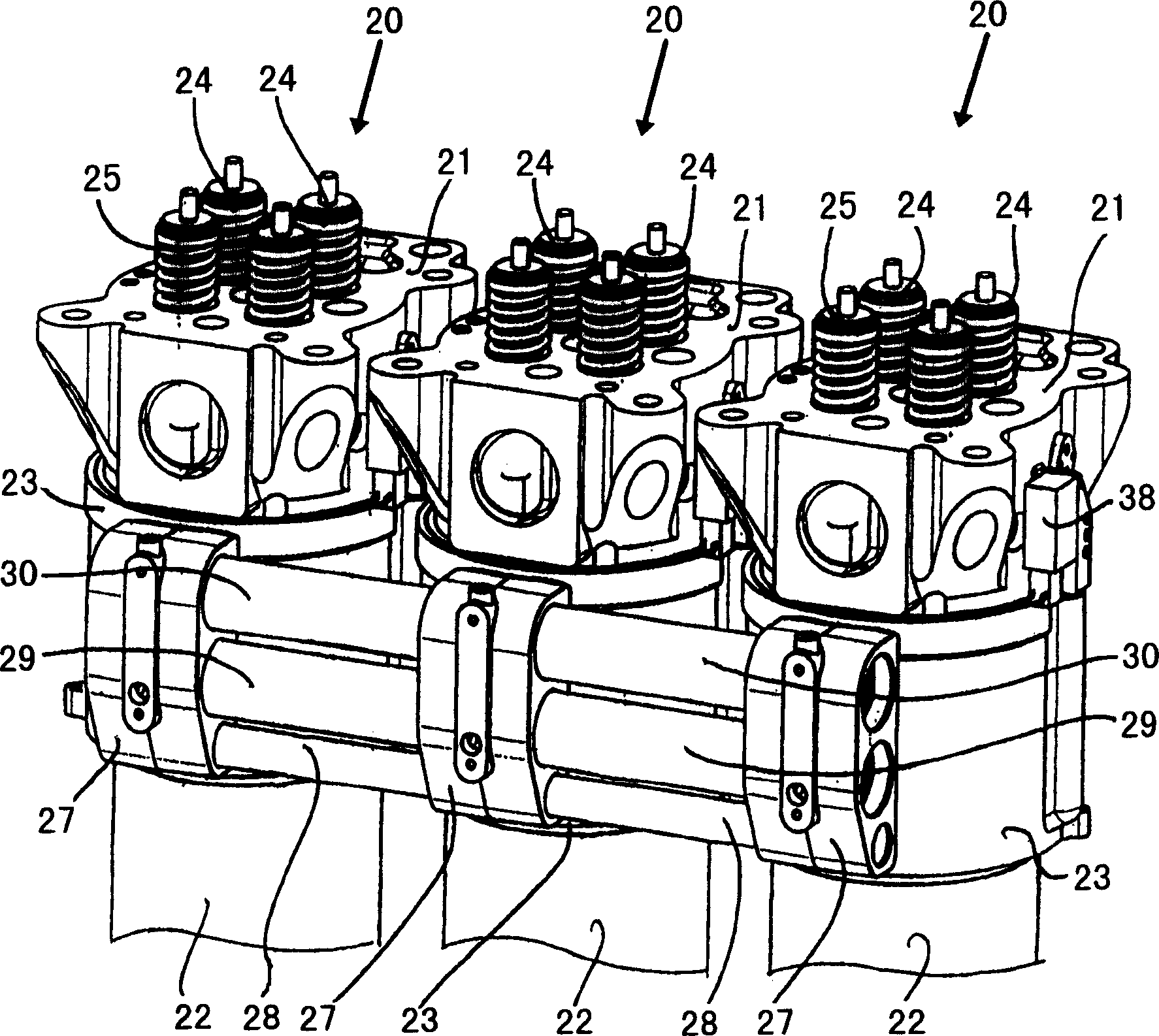

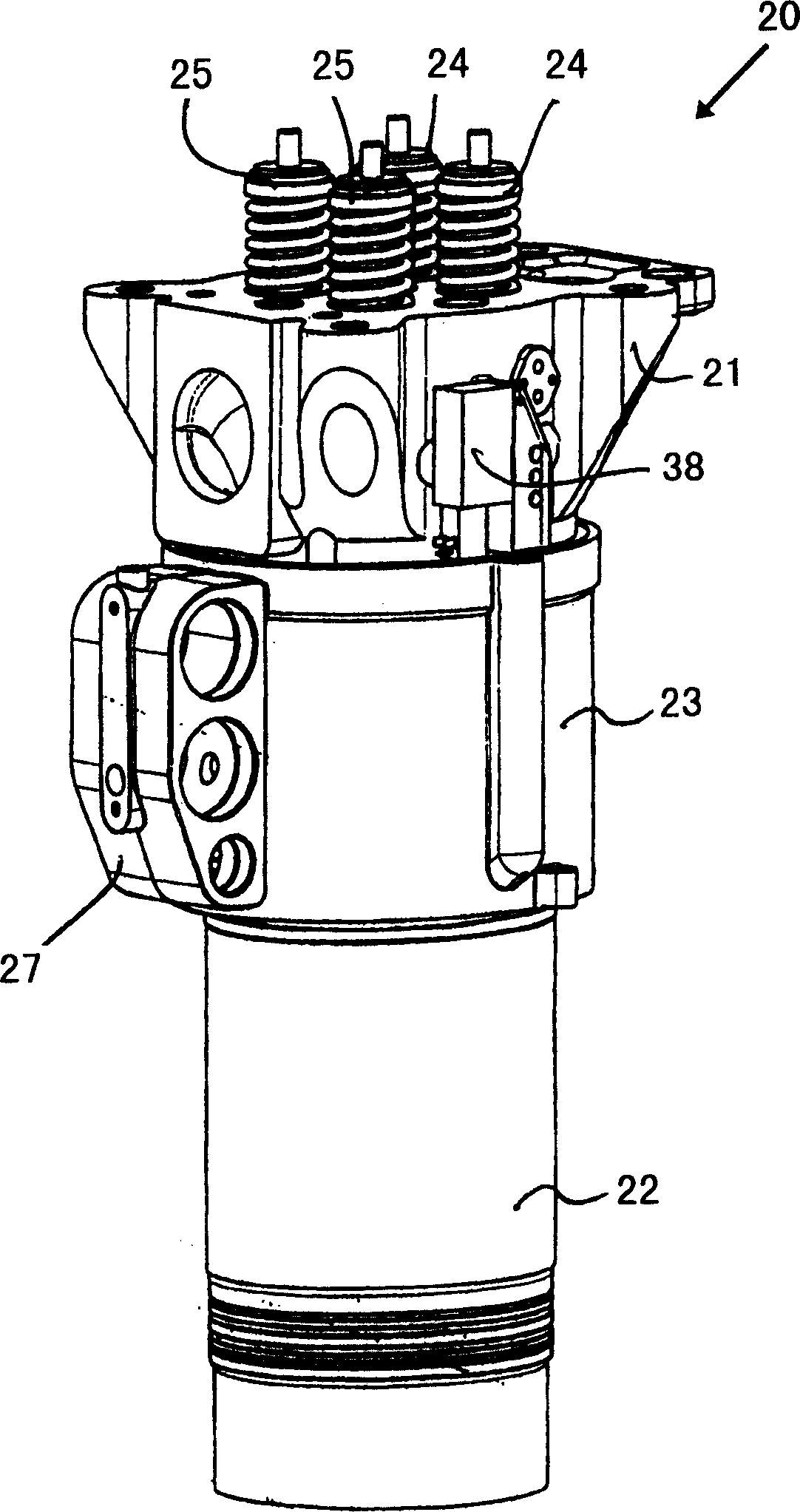

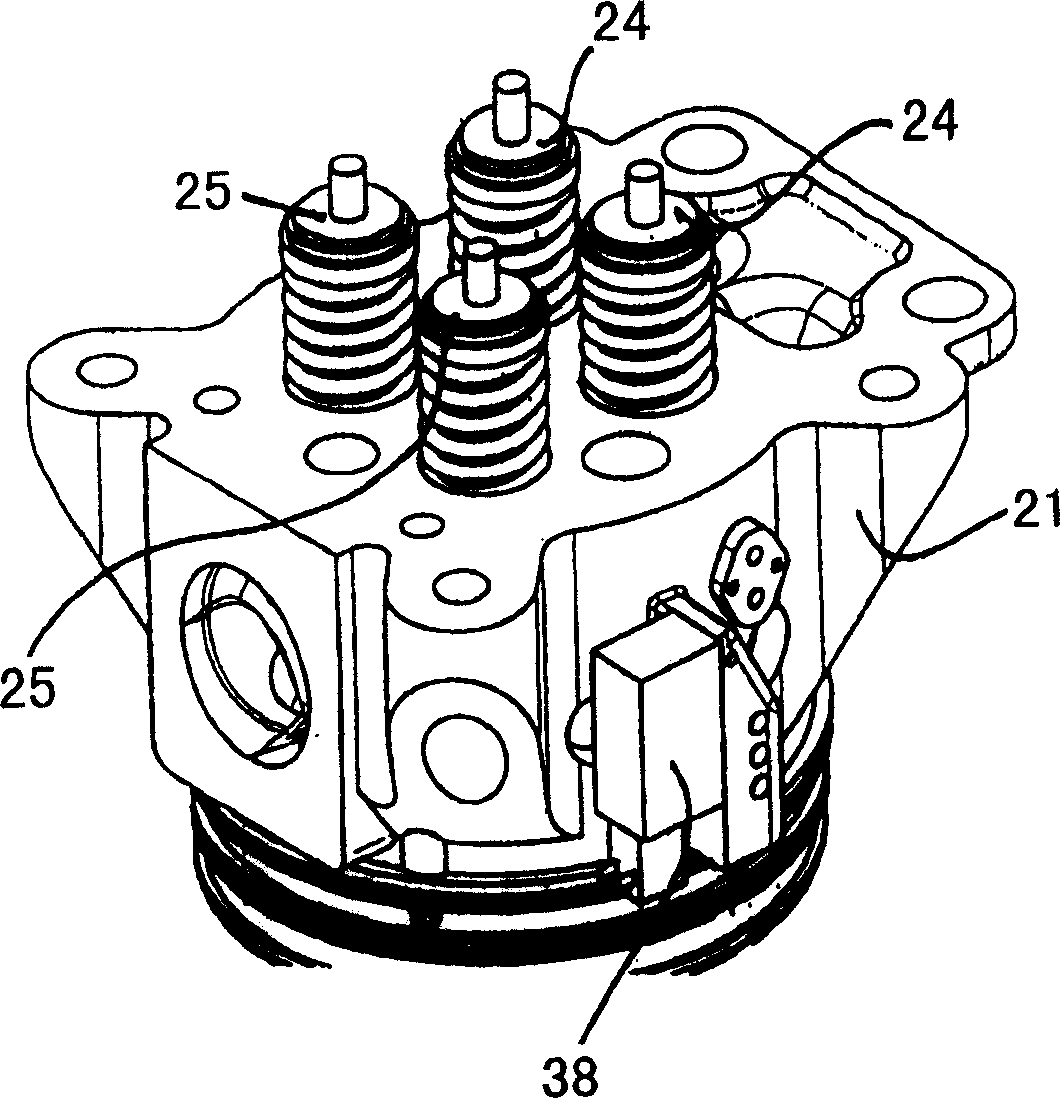

[0018] figure 1 Partially shows the area of three cylinder units arranged in a row in an internal combustion engine according to the invention, wherein each cylinder unit 20 comprises a cylinder head 21, a cylinder liner 22 and a duct arrangement 23 for cooling water and starting air . In the exemplary embodiment shown, two intake valves 24 for combustion air and two exhaust valves for exhaust gases are combined in the cylinder head 21 of each cylinder unit 20 . In the area between the intake valve 24 and the exhaust valve 25, the opening 26 combined in the cylinder head 21 (see Image 6 ) is integrated into the cylinder unit 20 for fuel, not shown. The pipe arrangement 23 for cooling water and starting air of each cylinder unit 20 surrounds the cylinder head 21 and the cylinder liner 22 of the respective cylinder unit 20 in a section at which the cylinder head 21 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com