Heat sink device for electronic equipment and method therefor

A heat dissipation device and electronic equipment technology, applied in lighting and heating equipment, machine operation mode, electrical digital data processing, etc., can solve problems such as sanitation problems, user inconvenience, and insignificant cooling effect, so as to improve heat dissipation efficiency, Reasonable use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

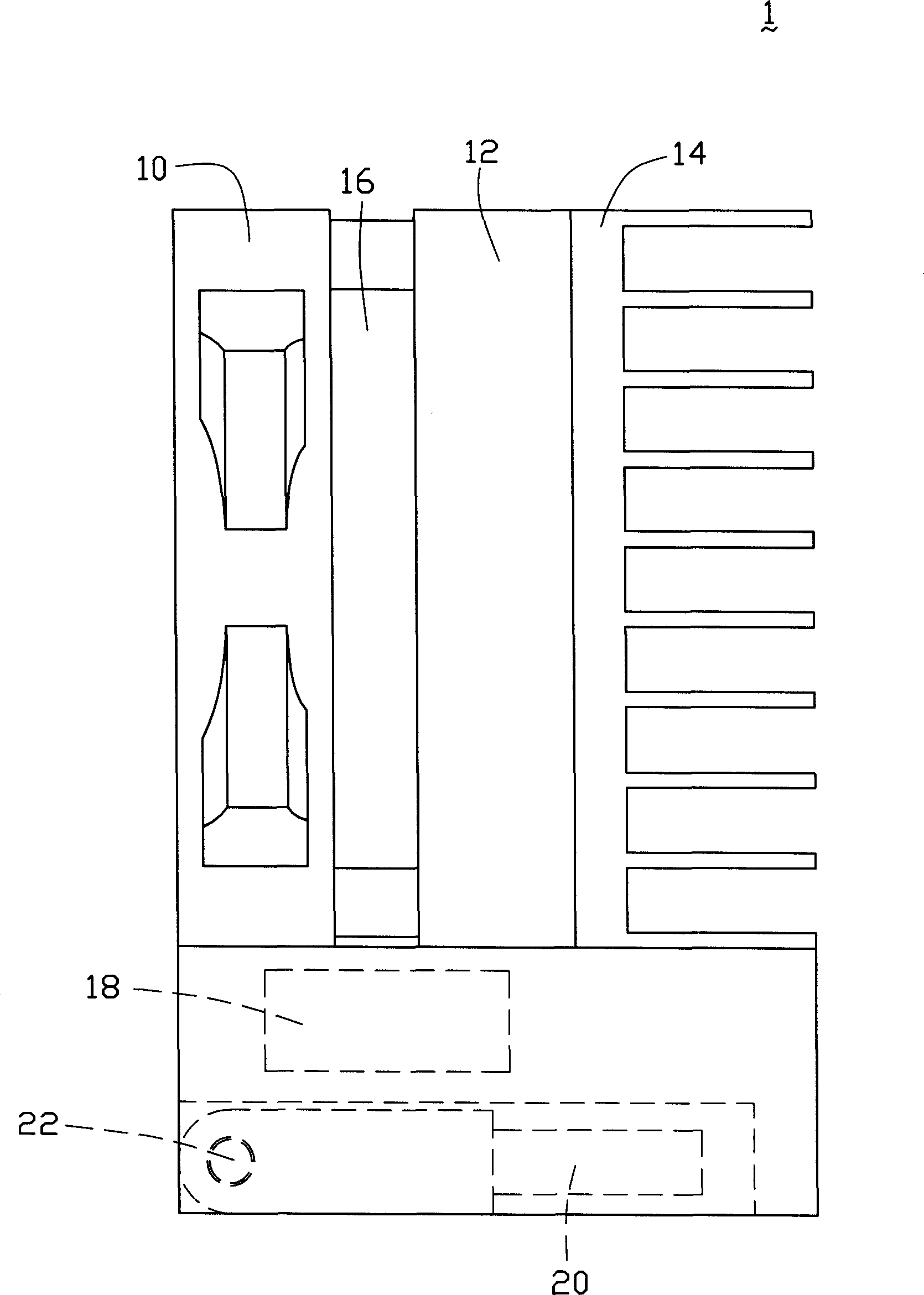

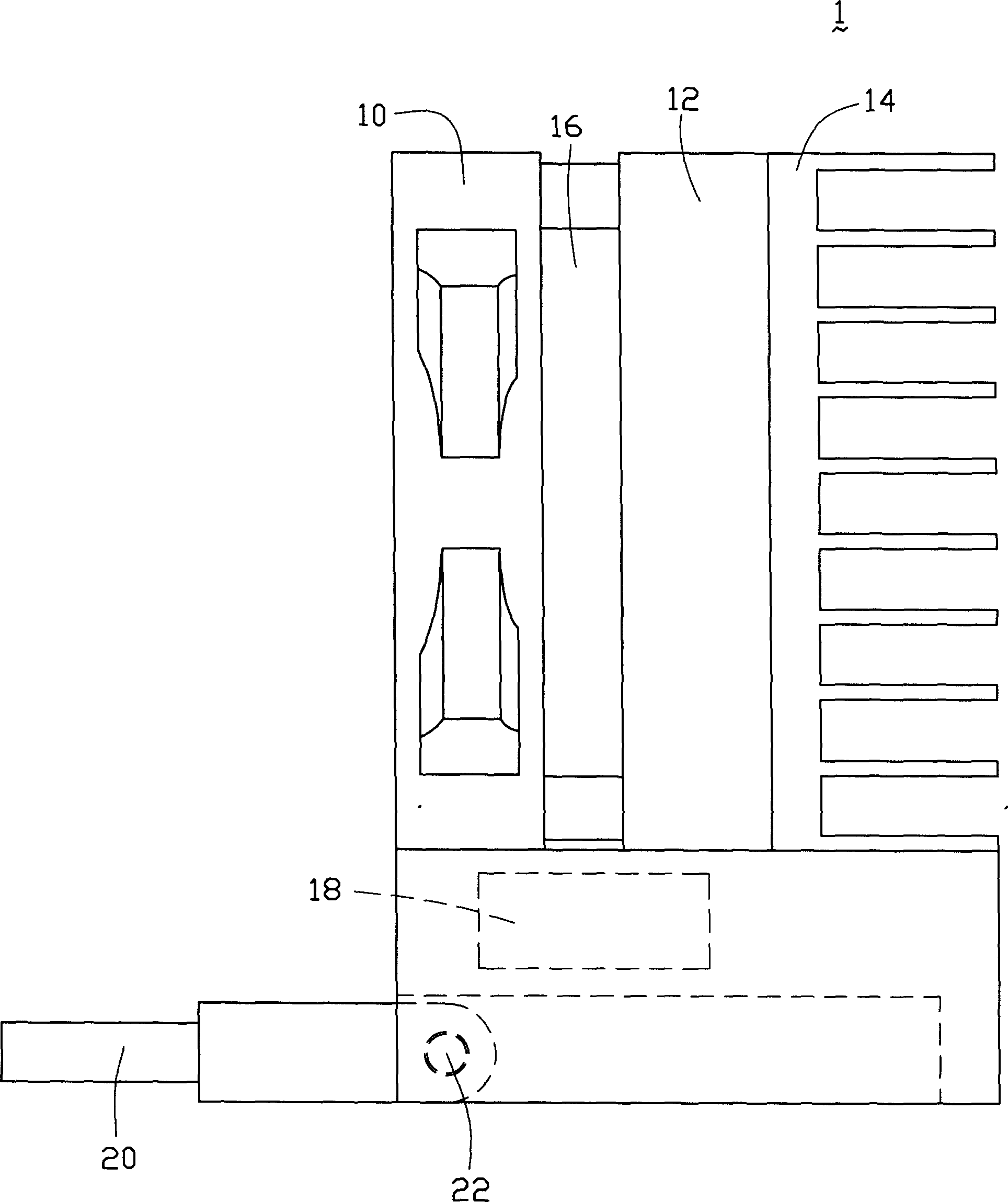

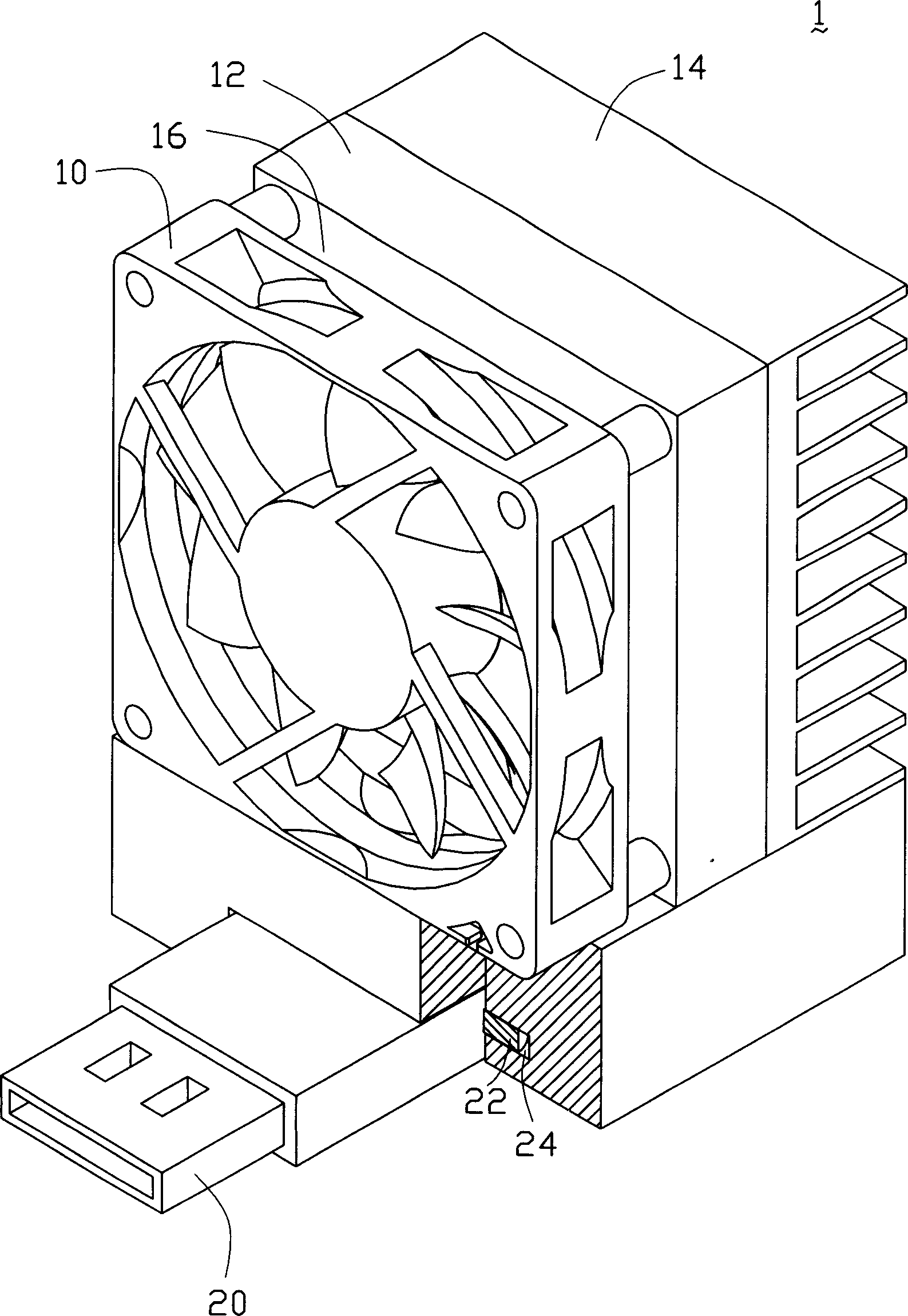

[0017] Such as figure 1 Shown is a heat dissipation device 1 of a preferred embodiment of the present invention, which includes an axial fan 10, a thermoelectric cooling device (Thermo-Electric Cooler, TEC) 12, a single-chip processing device 18, and an interface terminal 20 . The thermoelectric cooling device 12 is arranged in the axial air inlet direction of the axial flow fan 10 , its cold end is connected with the axial flow fan 10 , and its hot end is provided with cooling fins 14 . A gap 16 is provided between the axial fan 10 and the thermoelectric cooling device 12 as an air inlet of the axial fan 10 . The single-chip processing device 18 is electrically connected to the axial fan 10 and the thermoelectric cooling device 12 , and is used to control the speed of the axial fan 14 and the power of the single-chip processing device 18 . The interface terminal 20 includes a free end (not marked) and a fixed end (not marked) corresponding to the free end. The interface te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com