180 DEG three-decibel directional coupler of hemi-membrane substrate integrated waveguide

A half-mode substrate integration and coupler technology, which is applied to waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of difficult processing, high cost, large radiation loss, etc., and achieves low processing difficulty, low cost, Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

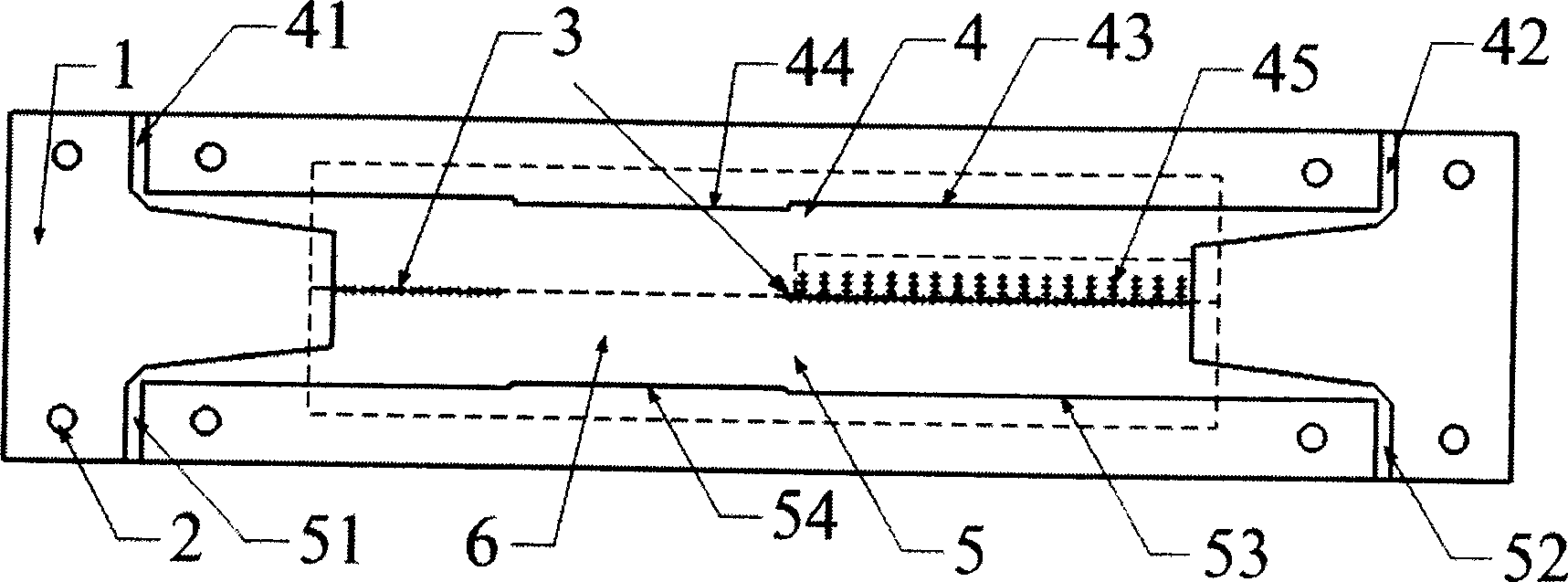

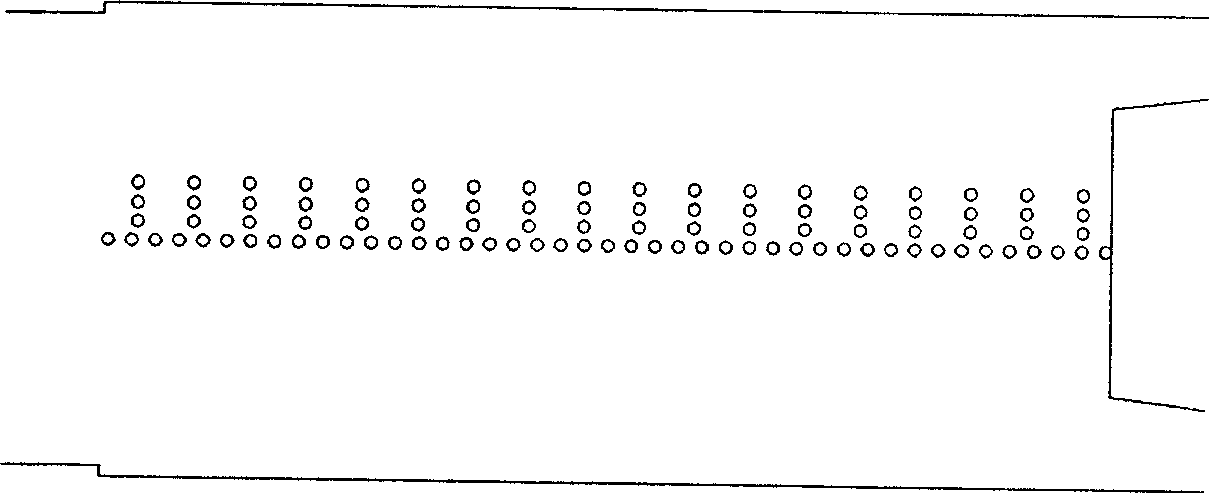

[0017] In the half-mode substrate integrated waveguide 180-degree three-decibel coupler of the present invention, a first half-mode substrate integrated waveguide 4 and a second half-mode substrate integrated waveguide 5 are respectively arranged on both sides of the midline of the front of the dielectric substrate 1. The two ends of the first half-mode substrate integrated waveguide 4 are the input terminal 41 and the output terminal 42 respectively, and the two ends of the second half-mode substrate integrated waveguide 5 are respectively the isolation terminal 51 and the coupling terminal 52. The substrate-integrated waveguide 4 and the second half-mode substrate-integrated waveguide 5 share a partition strip composed of a row of metallized through holes 3, and a coupling slit 6 is arranged on it. An upper metal notch 44 is provided on the opening surface of the half-mode substrate integrated waveguide 4 , and a lower metal notch 54 is provided on the opening surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com