Redundant automation system for controlling a technical device, and method for operating the same

A technology of automation system and process equipment, which is applied in the field of automation system, can solve the problems of complex application and expensive purchase, and achieve the effect of cost reduction and synchronization overhead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

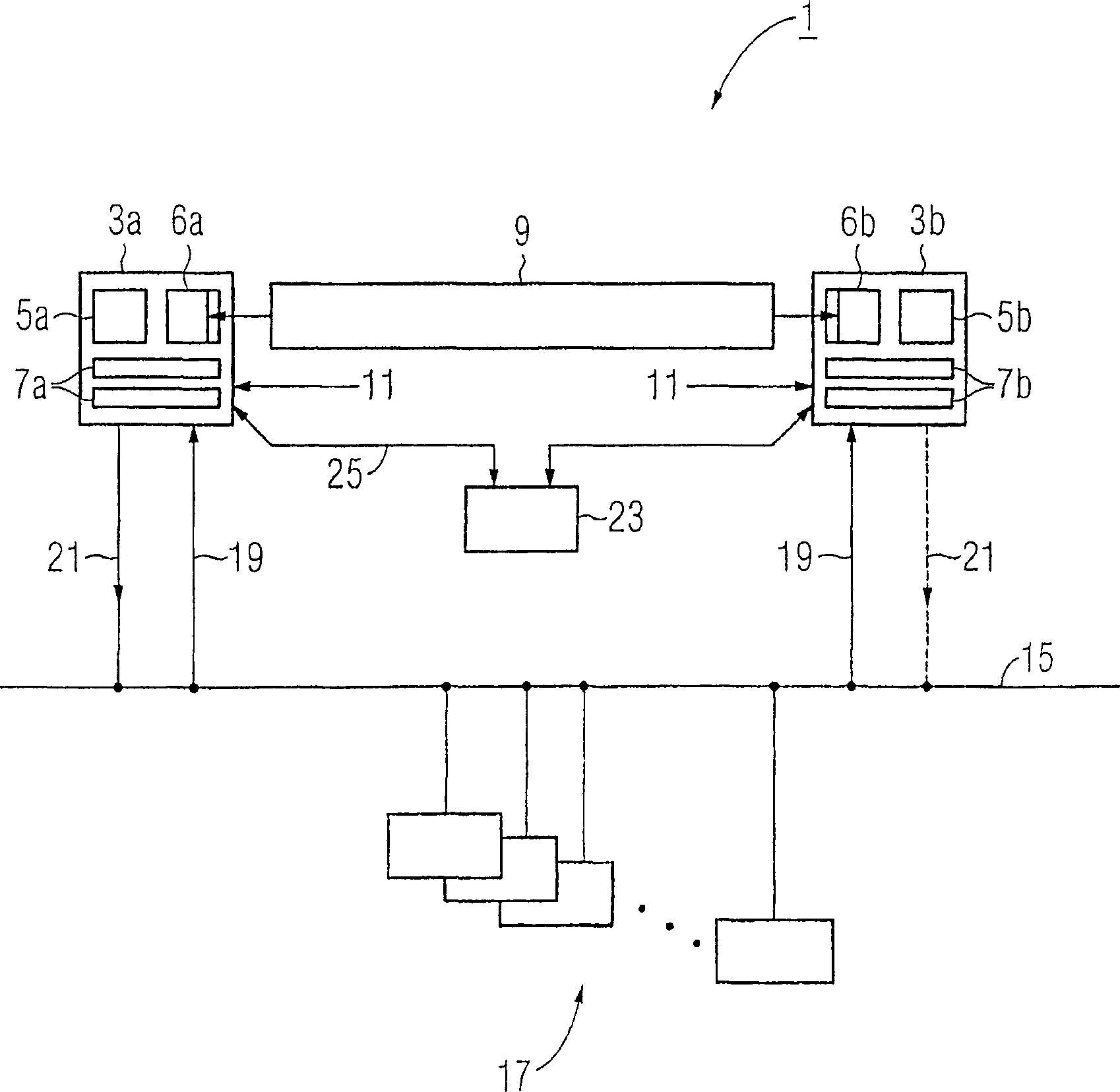

[0030] figure 1 A redundant automation system 1 according to the invention is shown, comprising automation devices 3a and 3b. In this case, the first automation device forms the master automation device 3a, which takes over the control of the process plant. Signals from the process equipment and control commands to the process equipment are processed here by the field device 17 and transmitted via the field bus 15 to the automation devices 3 a and 3 b.

[0031] In the event of a failure of the first automation device 3a, a second automation device is available as a backup automation device 3b and can assume the control tasks of the first automation device 3a.

[0032] A monitoring module 23 is provided for fault detection and switching from the first automation device 3 a to the second automation device 3 b. The monitoring module 23 analyzes the life characteristics 25 of the first automation device 3a and switches to the second automation device 3b in the event of a failure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com