Method and apparatus for performing an in-mold coining operation

一种模具、压力的技术,应用在注射压缩模制领域,能够解决模具不能被设计成接受型芯型芯等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

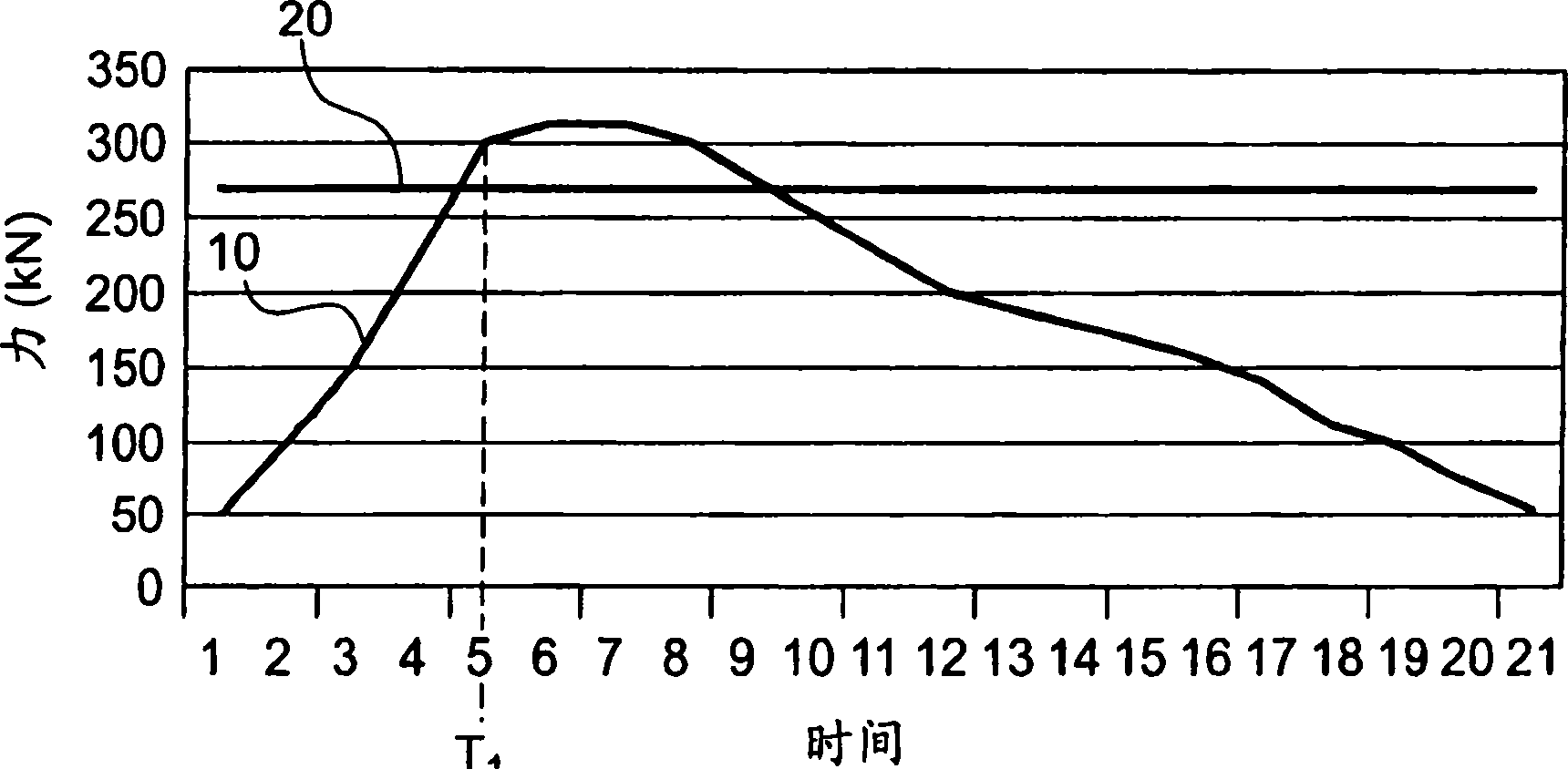

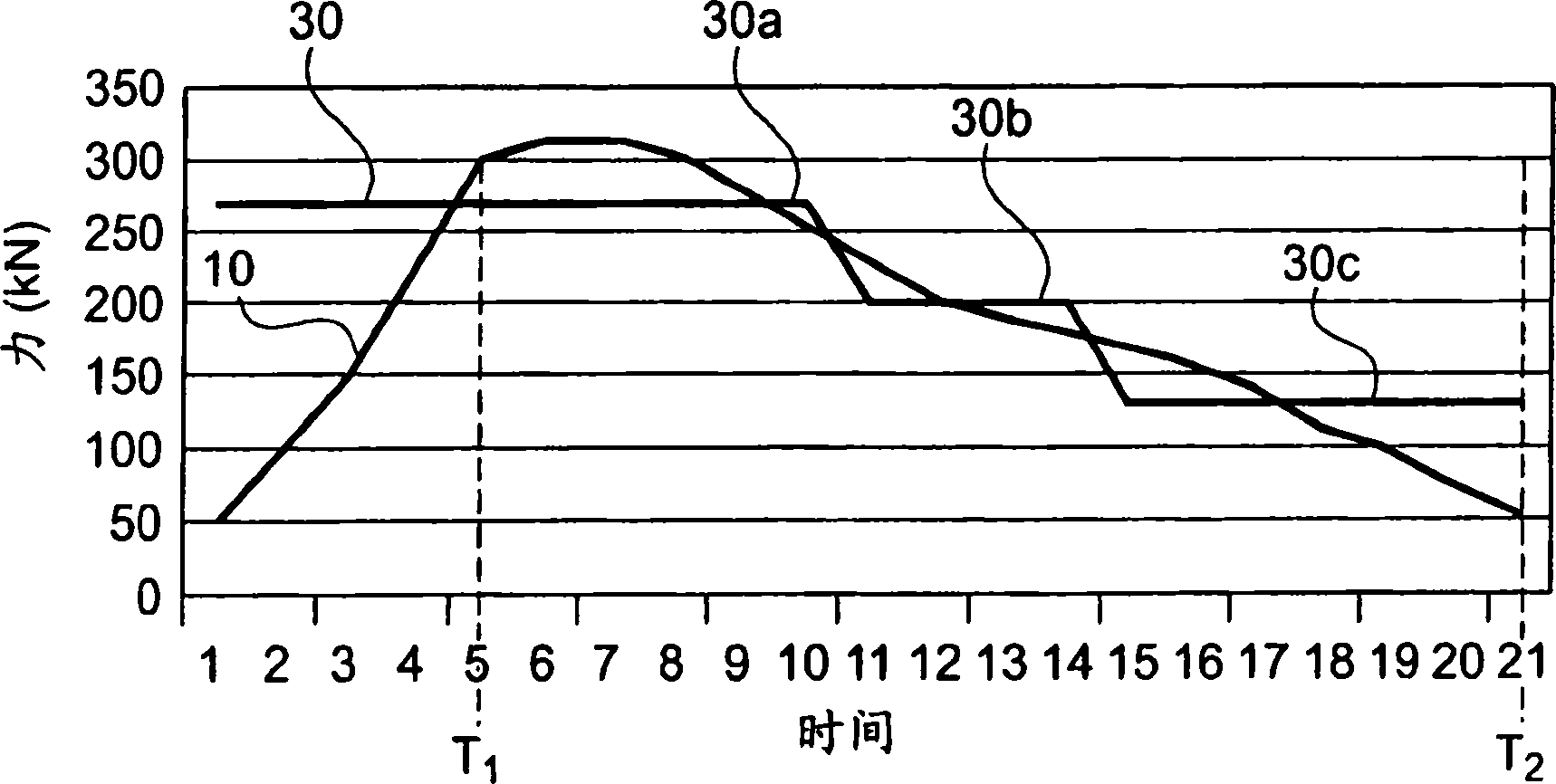

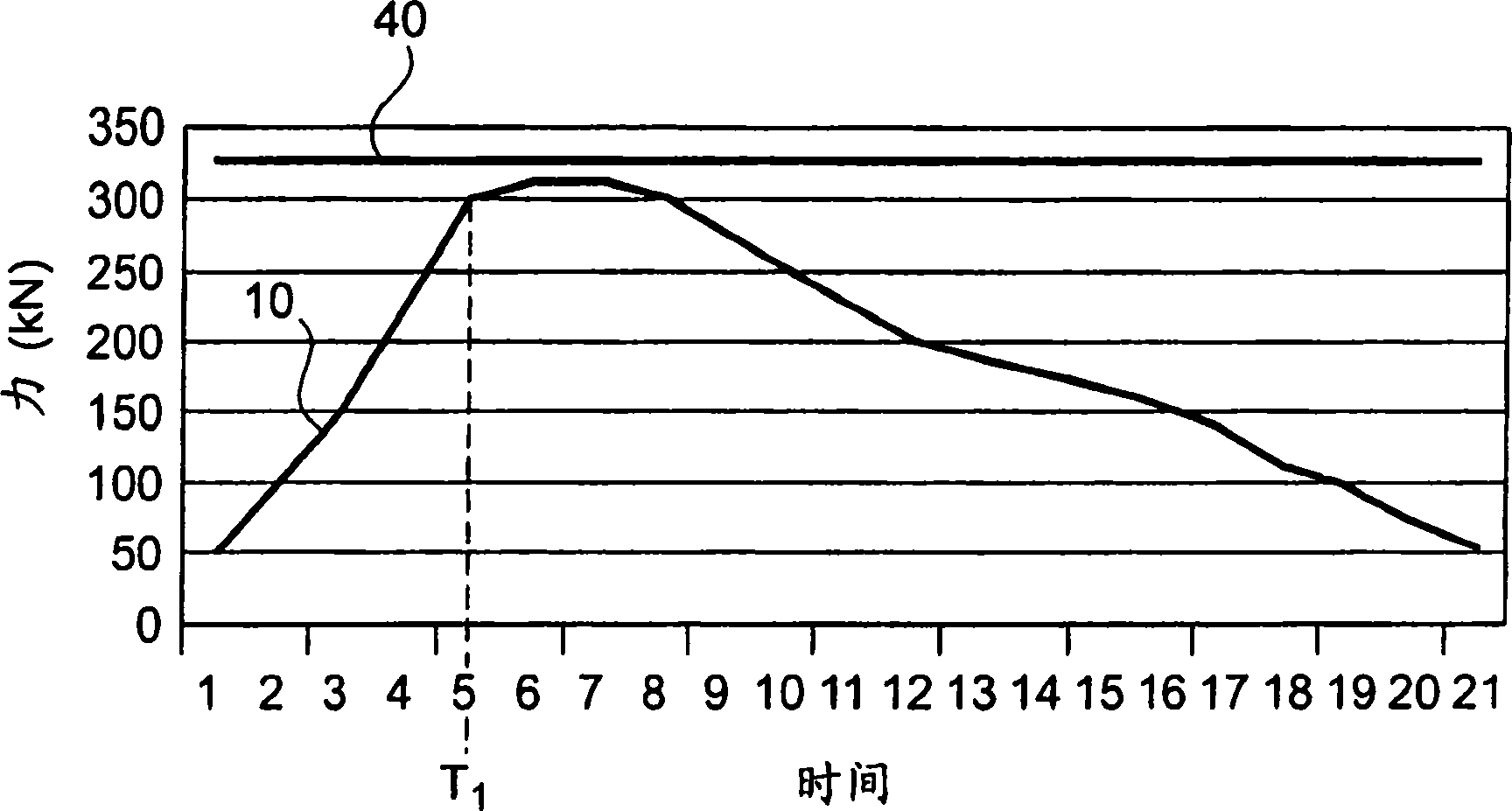

[0021] In general, injection compression molding is characterized by a compression phase in which the core compresses into contact with the molding material as it cools. This compression is reproduced by molding by bringing the core into intimate contact with the molding material as the compressed material shrinks. Components that have different thicknesses across their profile exhibit different degrees of shrinkage based on thickness, like ophthalmic lenses made of polycarbonate.

[0022] While compression helps improve mold reproduction, it creates challenges in controlling part thickness. The compression phase automatically changes the distance between the cores, thereby changing the target cavity thickness. One solution to this problem is to secure the core to the mold at the target cavity thickness. Then, in a so-called clamping stop, the entire mold half is displaced or slightly opened during the coining operation.

[0023] Referring now in detail to the drawings, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com