Bending beam type motorcycle frame and the fixing mounting structure of its fittings

An installation structure and technology for motorcycles, applied in motorcycles, bicycle accessories, motor vehicles, etc., can solve problems such as affecting the appearance of the rear of motorcycles, and achieve the effects of reducing installation gaps, strong overall sense, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

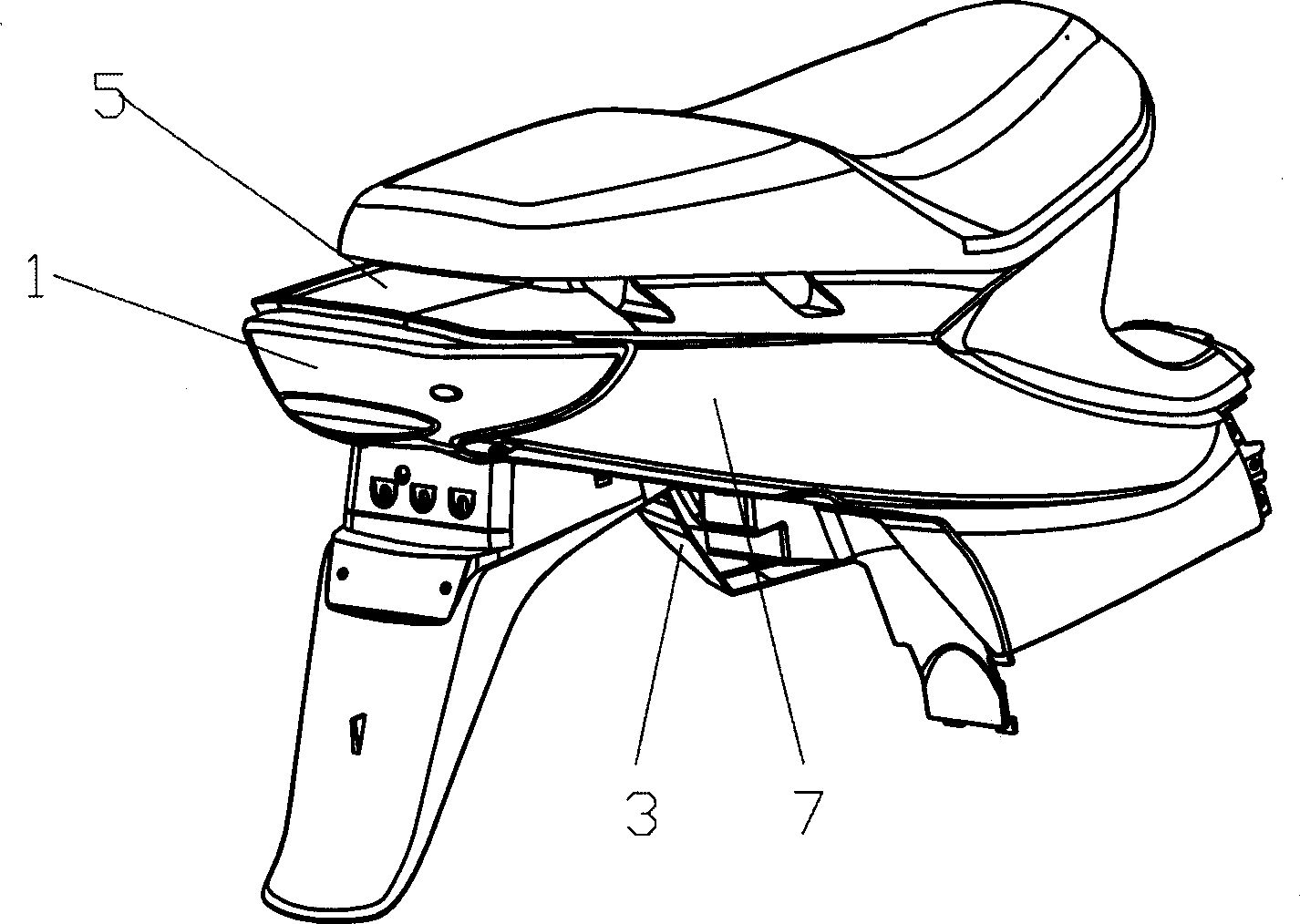

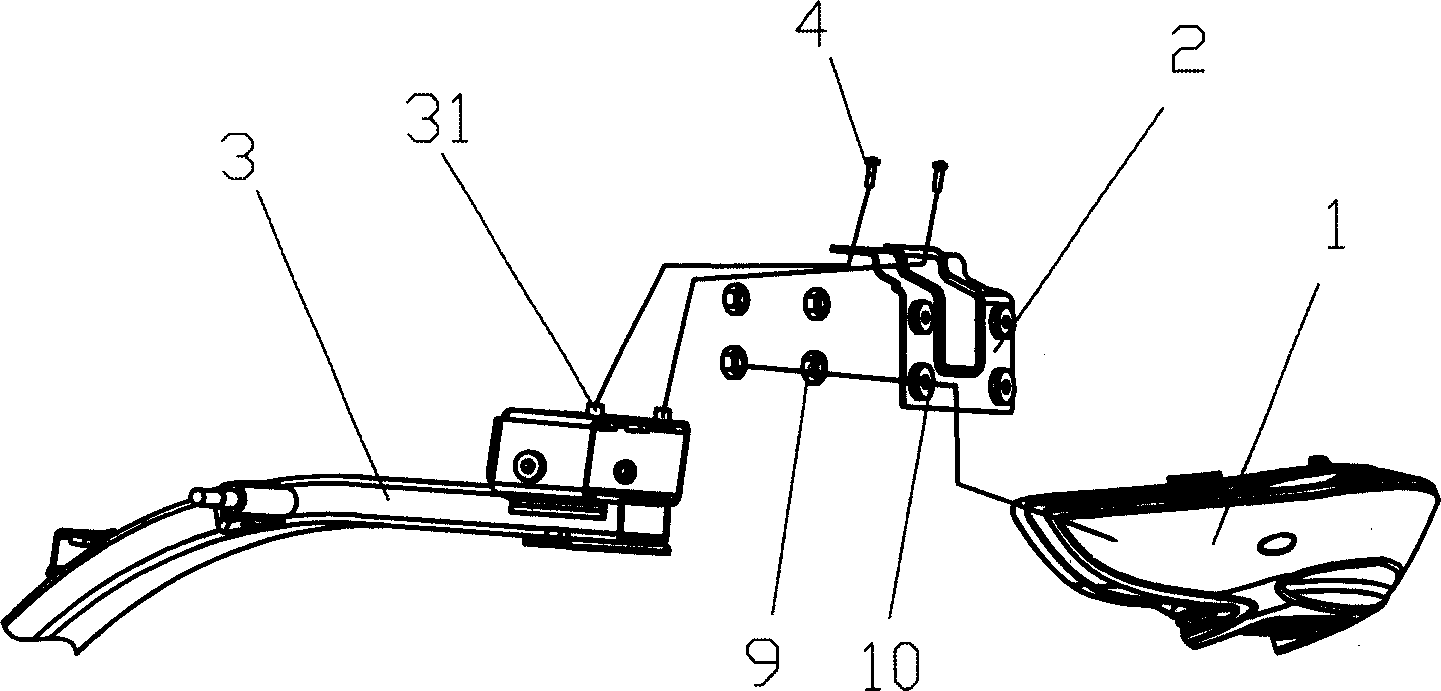

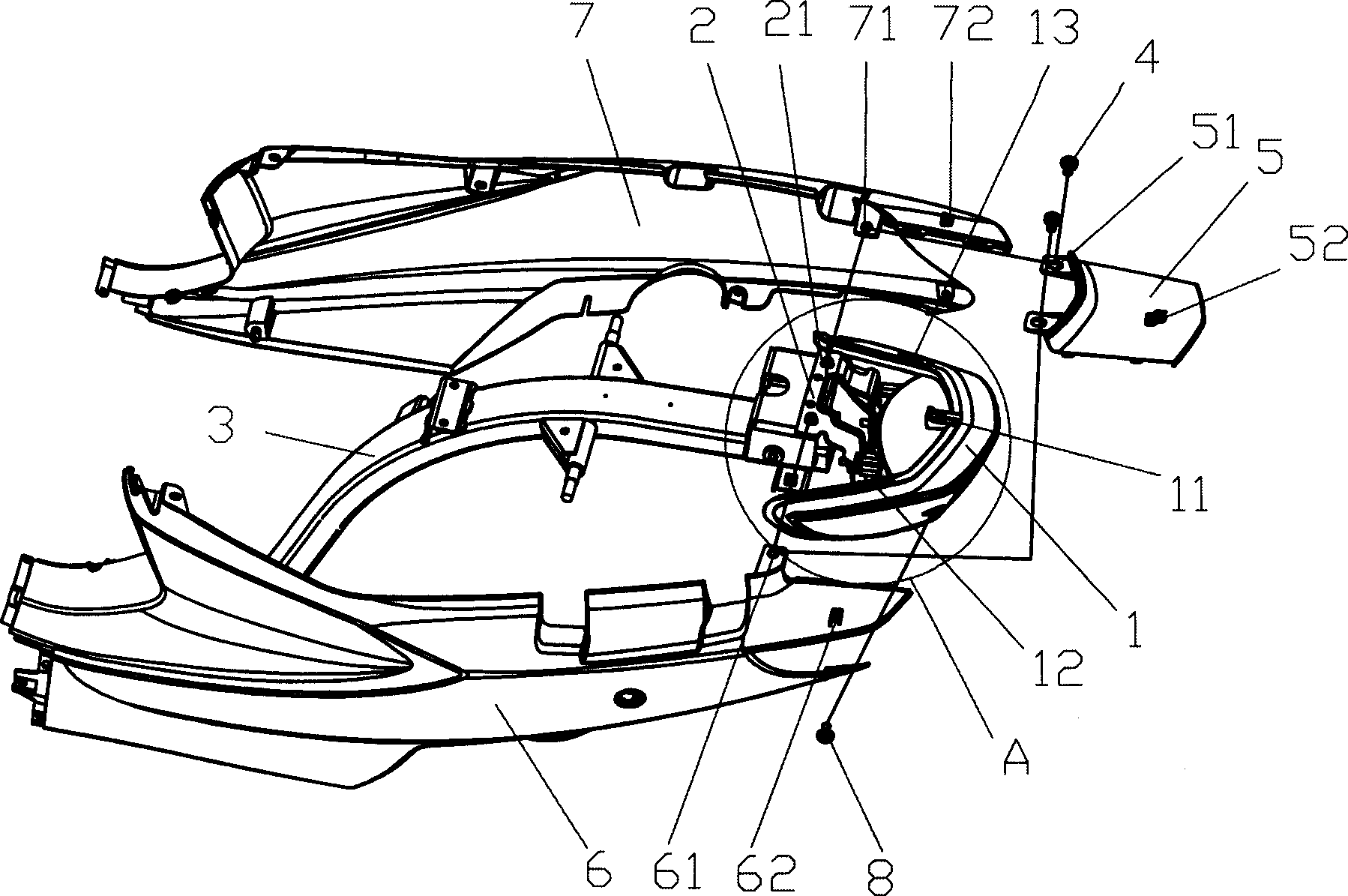

[0014] refer to figure 1 , figure 2 , image 3 , Figure 4 , a fixed installation structure between the frame of a curved beam motorcycle and its accessories, the accessories include a tail light 1, a tail cover 5 and left and right side covers 6, 7 of the car body, the tail light 1 The metal bracket 2 is hung on the boss 31 above the vehicle frame 3, and the taillight 1 and the metal bracket 2 are fixedly installed together by the fixing bolt 9. In order to facilitate buffering, a rubber pad 10 is installed between them. The metal bracket 2 is provided with a bar-shaped hole 21 that can adjust the front and rear distance between the taillight 1 and the vehicle frame 3, and the mounting bolts 4 pass through the tail cover mounting hole 51, the left and right car body side cover mounting holes 61, 71, and the metal bracket respectively. The strip hole 21 on the support 2 is fixedly installed on the vehicle frame 3 with the tail light 1, the tail cover 5, the left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com