Assemblies of headlamps and means for mounting such headlamps that limit repairs to adjacent fenders in the event of a collision, and corresponding vehicles

A technology for mounting devices and headlights, which is applied in the field of vehicles and can solve the problems of increasing the range of movement of headlights and increasing damage to surrounding components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

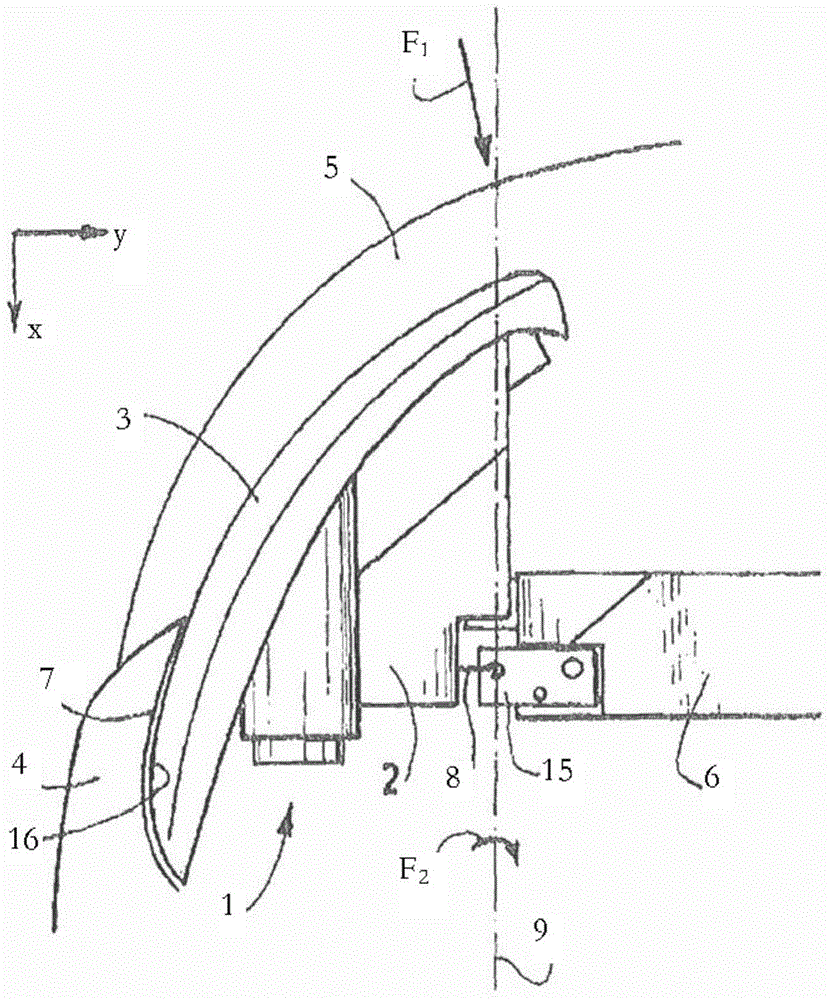

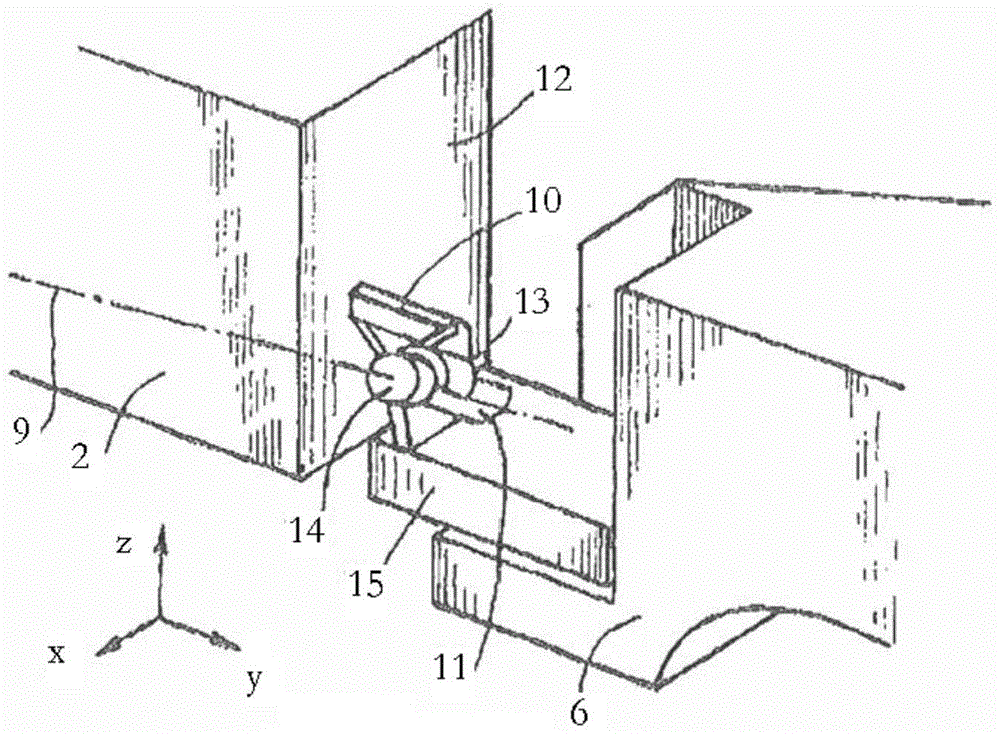

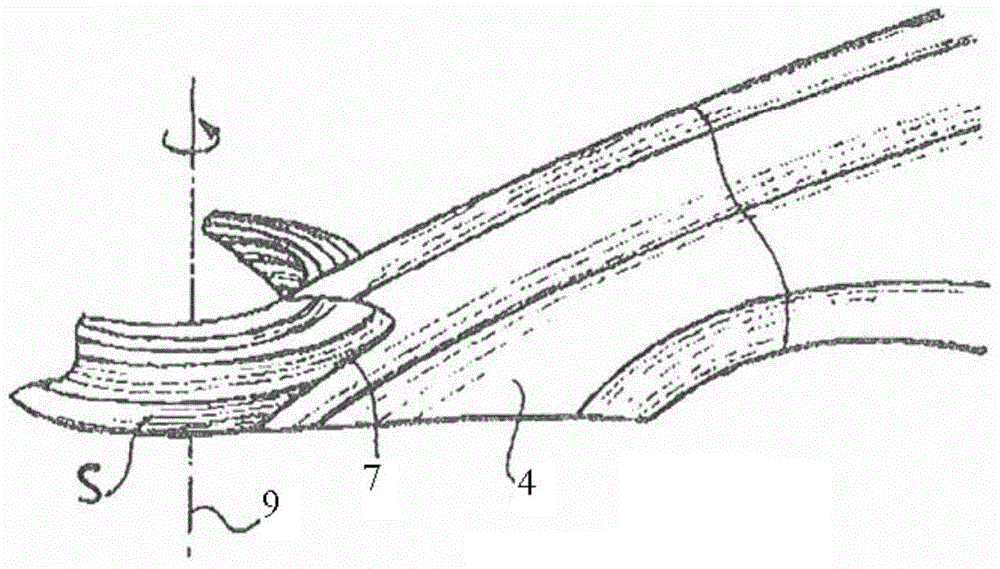

[0040] In this specification, when a headlight is mounted on a vehicle, the terms front, rear, upper and lower refer to the front and rear of the vehicle. The axes X, Y, Z correspond respectively to the longitudinal axis (from front to the rear), the transverse axis and the vertical axis of the vehicle.

[0041] see figure 1 , shows a front headlamp 1 of the vehicle comprising a housing 2 equipped with a lens 3 enclosing one or more light sources (not shown).

[0042] exist figure 1 Also shown in part is a fender 4, the lower part of the front apron 5 and the technical front end (TFE) 6 of the vehicle, which typically supports the cooling unit (radiator, fan, etc.) for the propulsion unit And connect various structural elements of the vehicle.

[0043] like figure 1 and Figure 3 to Figure 5 As can be seen in , the headlight 1 is mounted partly along an edge 7 of the fender 4 of the vehicle.

[0044] A mounting device mounts the headlamp on the structural elements of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com