Multi-contact independent movement structure

An independent movement, multi-contact technology, applied in the direction of circuit breaker contacts, protection switch operation/release mechanism, circuit breaker components, etc., can solve the problems affecting product performance and high installation process requirements, so as to improve product use performance, guaranteed current-carrying area, and the effect of large maximum rated current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Below in conjunction with accompanying drawing this embodiment is described in detail:

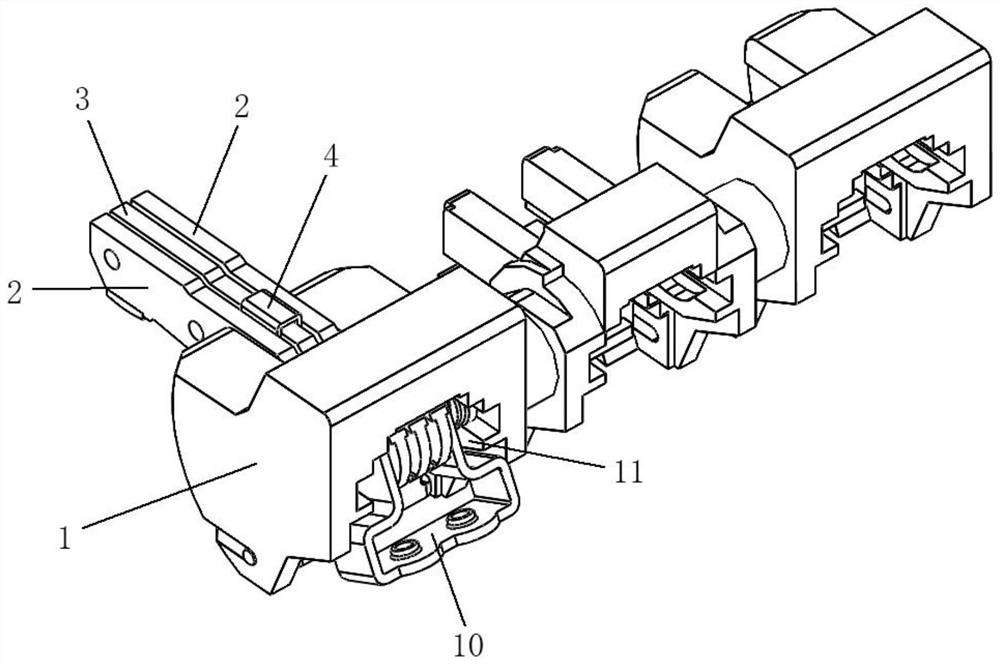

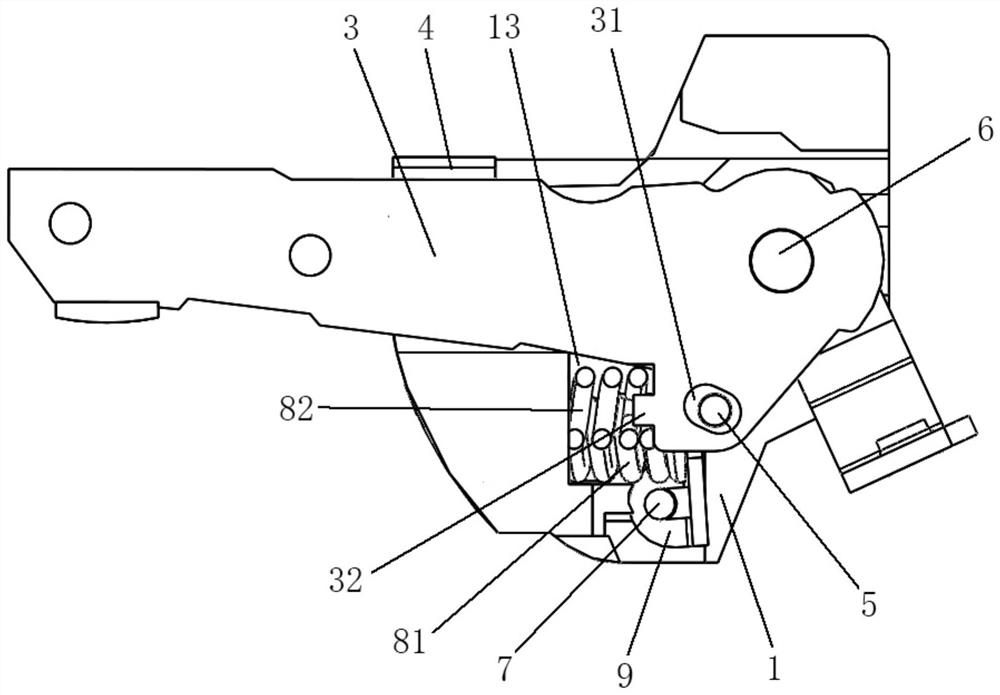

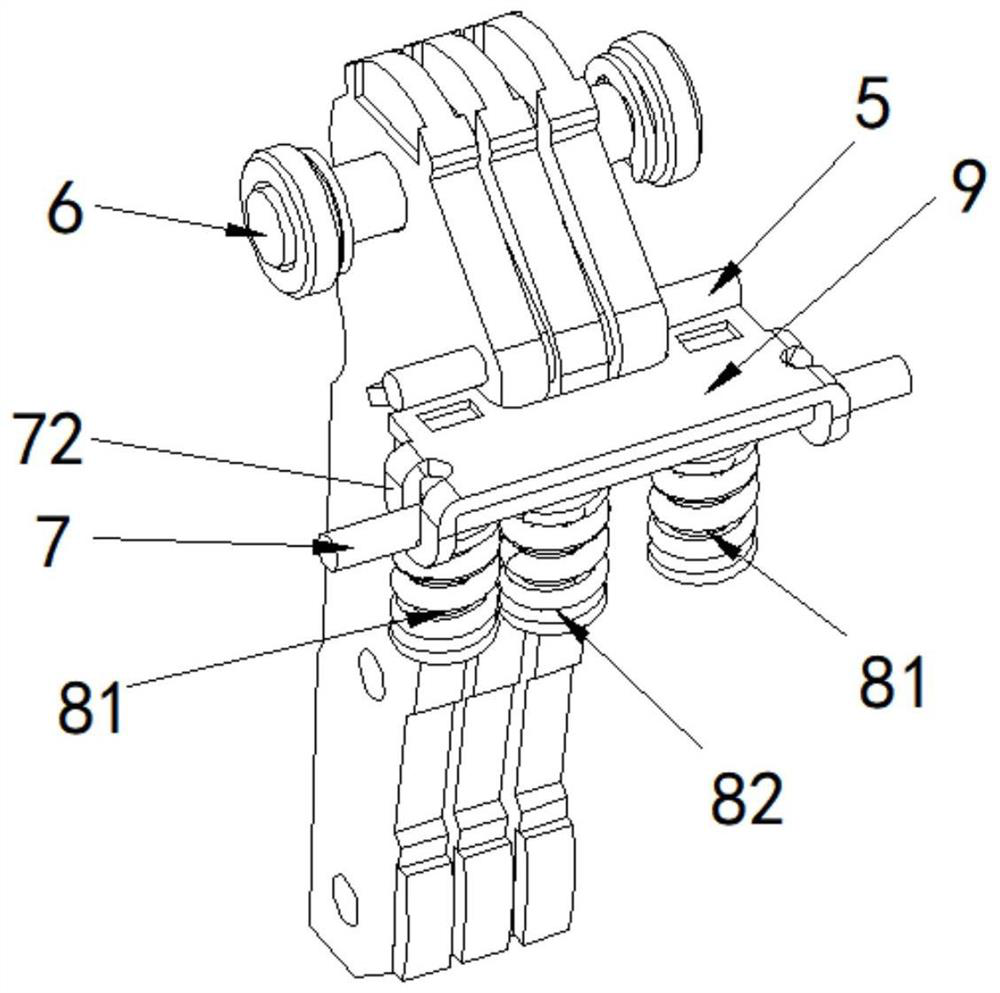

[0043] This embodiment provides as Figure 1-10 The shown multi-contact independent movement structure is used on molded case circuit breakers, which includes a rotating shaft structure 1, and a moving contact assembly arranged on the rotating shaft structure 1 through the first rotating shaft 6 to rotate side by side, and The contact spring assembly 8 arranged between the moving contact assembly and the shaft structure 1, the moving contact assembly includes two first contacts 2 arranged on the outermost side, and the two first contacts At least one second contact 3 between the contacts 2, and the contact cover structure 4 arranged between the two first contacts 2 and the second contacts 3 through the rotation of the first rotating shaft 6, the two first contacts The head 2 and the second contact 3 are relatively rotatable around the first rotating shaft 6, and the contact sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com