Automatic visual detection device for regulator

A visual inspection device and regulator technology, applied in sorting and other directions, can solve the problems of low efficiency, uneven quality, and large error in manual inspection of the regulator, and achieve high detection efficiency, guaranteed yield, and high accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The product of this embodiment is a military regulator.

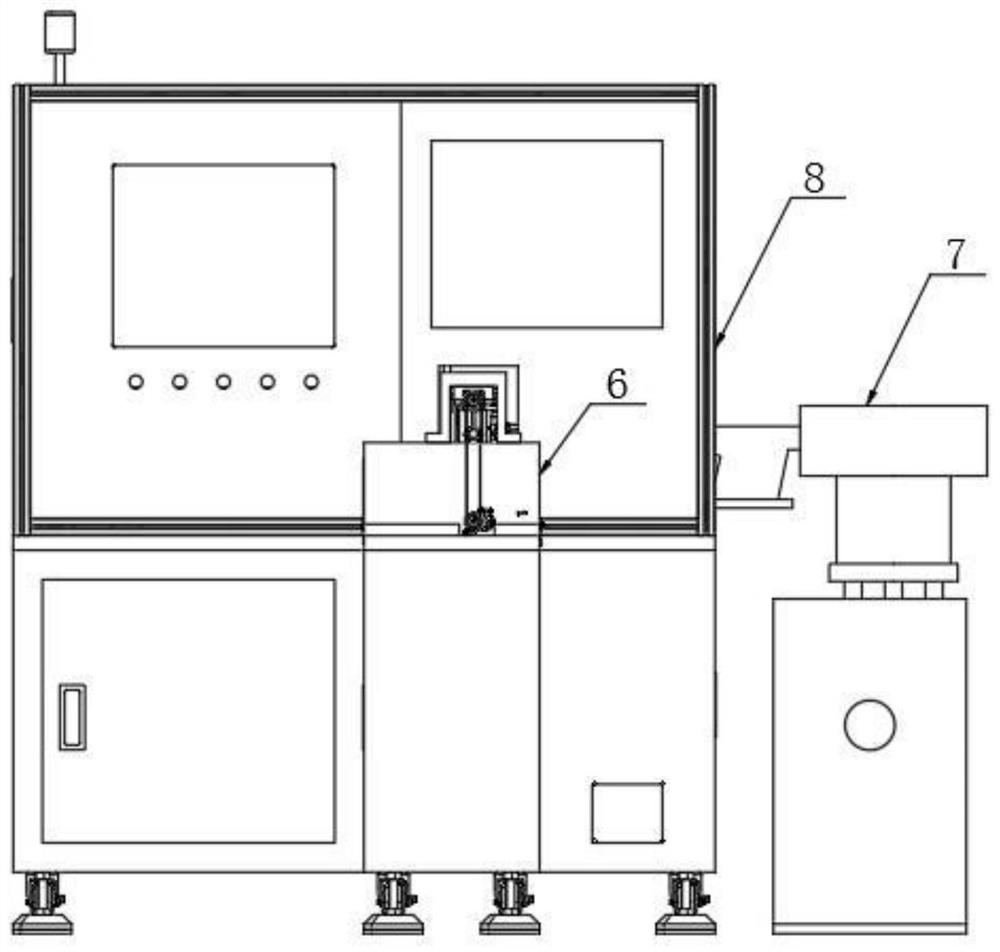

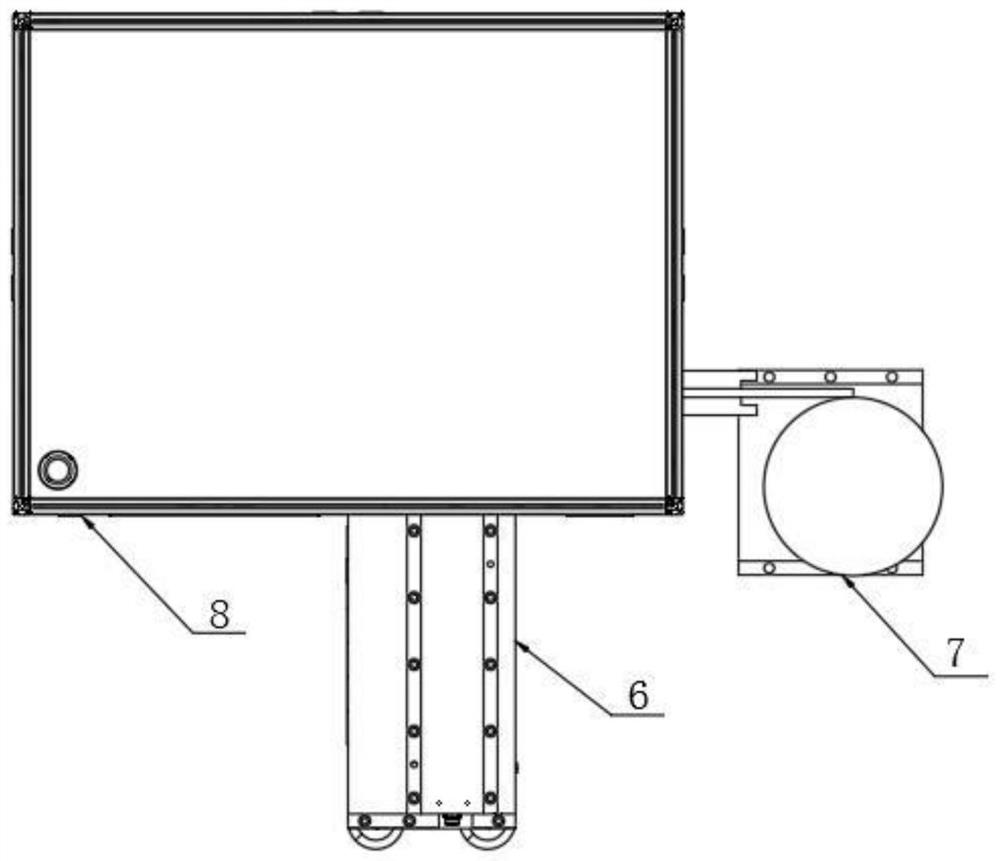

[0055] refer to Figure 1 to Figure 13 , the automatic visual inspection device for the regulator of the present invention, comprising:

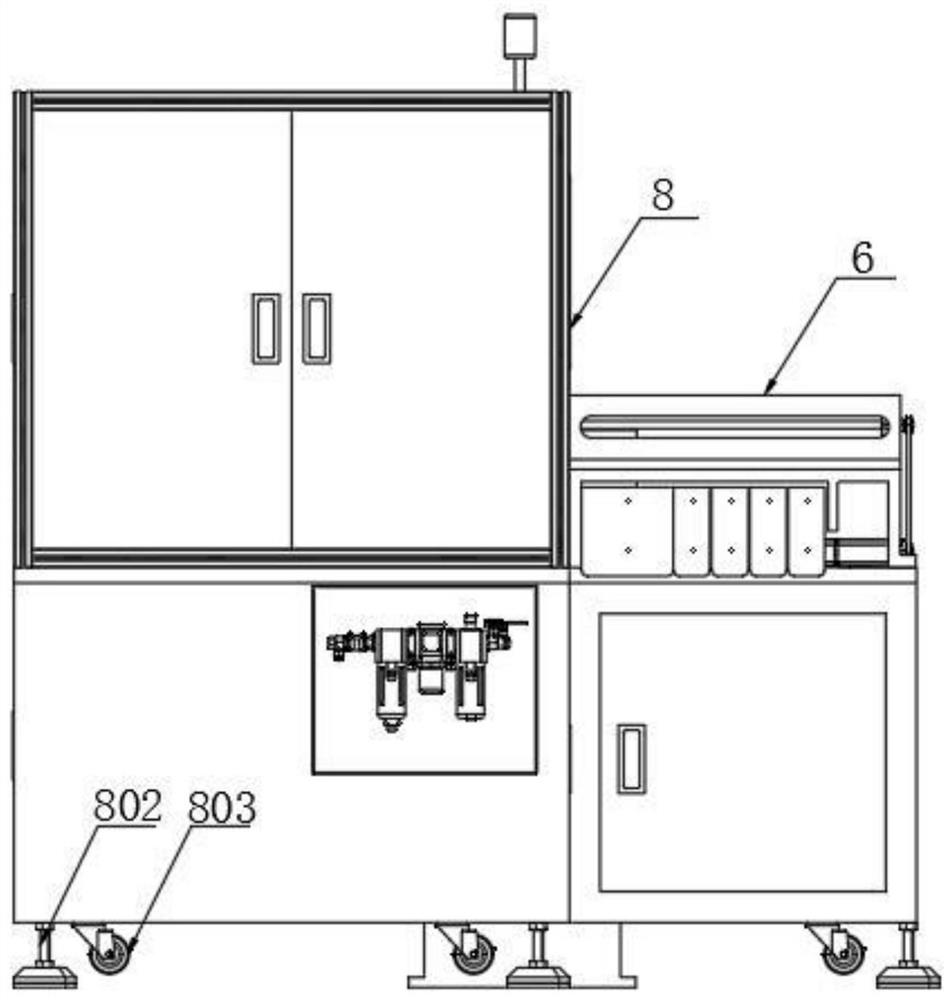

[0056] A cabinet 8, a bottom plate 801 is arranged horizontally in the cabinet;

[0057] The feeding mechanism 7 is arranged on the side of the cabinet 8, and is used for feeding and transporting products;

[0058] The first detection station 1 is arranged on the bottom plate 801 and is used to detect whether the characters on the bottom of the product are correct;

[0059] The second detection station 2 is arranged on the bottom plate 801 and is used to detect whether there is a scratch in the annular groove on the surface of the product;

[0060] The third detection station 3 is arranged on the bottom plate 801, and is used to detect whether the aperture of the side hole on the side of the product is correct;

[0061] The fourth detection station 4 is arranged on the bott...

Embodiment 2

[0073] refer to Figure 11, on the basis of Embodiment 1, this embodiment is provided with a marking mechanism on the side of the blanking mechanism for marking on the product; the marking mechanism includes a horizontally arranged pen-shaped cylinder 901, the movable end of the pen-shaped cylinder A hoop 902 is provided, and a marking pen (not shown in the figure) is fixed on the hoop. When the detected product is unqualified, the pen-shaped air cylinder stretches out to drive the marking pen to move. With the movement of the product, the marking pen makes a mark on the product, which is convenient for subsequent operators to identify.

Embodiment 3

[0075] On the basis of Embodiment 1, this embodiment is provided with a first fine-tuning mechanism and a first adjustment mechanism on the first camera; a second fine-tuning mechanism and a second adjustment mechanism are provided on the second camera; A third fine-tuning mechanism and a third adjusting mechanism are set; a fourth fine-tuning mechanism and a fourth adjusting mechanism are set on the fourth camera; a fifth fine-tuning mechanism and a fifth adjusting mechanism are set on the fifth camera;

[0076] The structures and principles of the first fine-tuning mechanism, the second fine-tuning mechanism, the third fine-tuning mechanism, the fourth fine-tuning mechanism and the fifth fine-tuning mechanism are the same; the first regulating mechanism, the second regulating mechanism, the third regulating mechanism, the fourth regulating mechanism and The structure and principle of the fifth regulating mechanism are the same.

[0077] refer to Figure 13 , taking the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com