Method of manufacturing needles for textile machines

A technology of textile machinery and needle latch, which is applied in the field of loop-forming textile machinery needles, can solve the problems that different requirements of mechanical properties are difficult to achieve, and achieve the effect of low reprocessing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

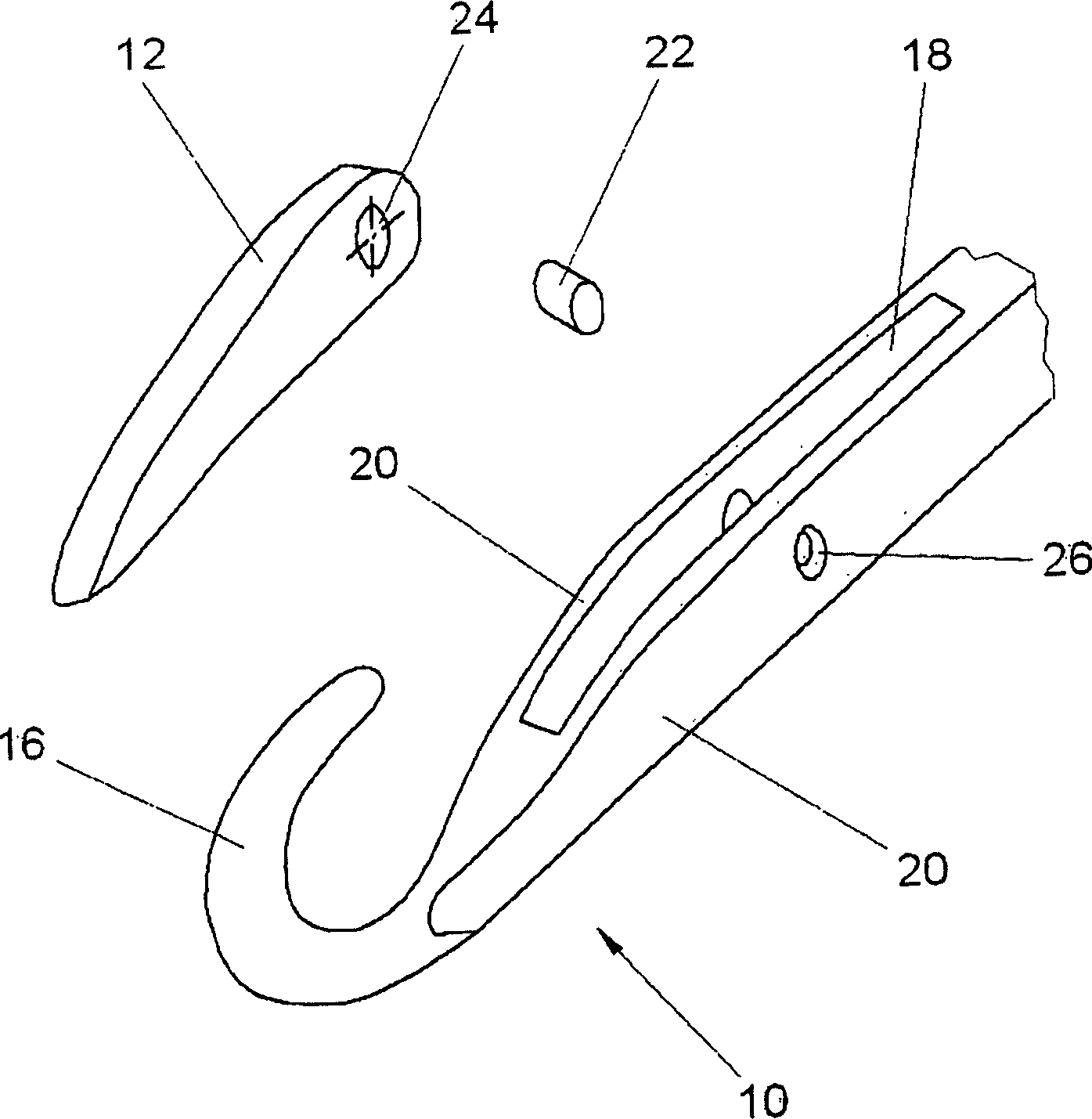

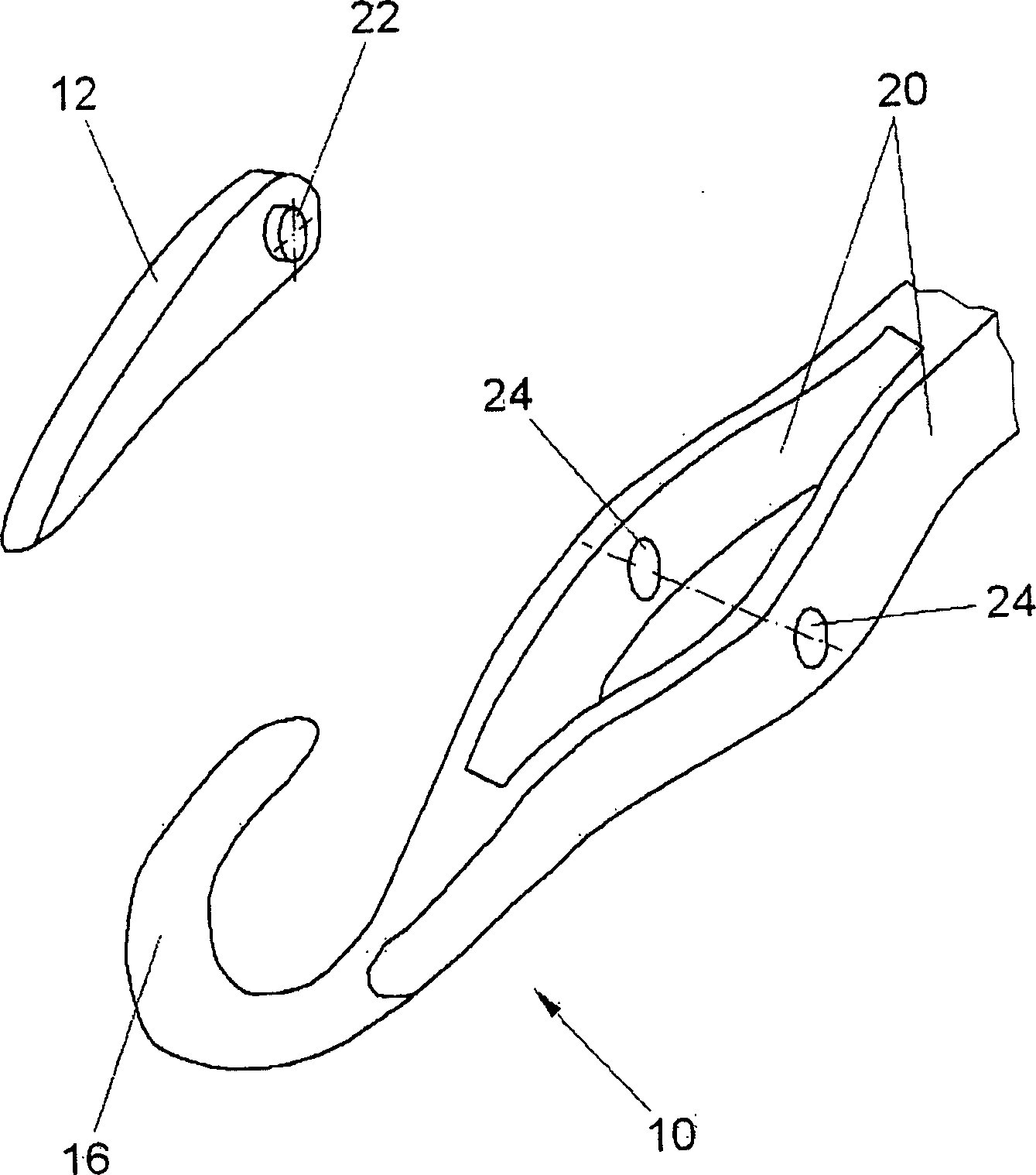

[0032] figure 1 The point of the latch needle is shown in a perspective exploded view. This needle point is made up of needle head 10 and needle latch 12. The needle tip is fixed on a figure 1 On the front end of the needle bar 14 not shown in.

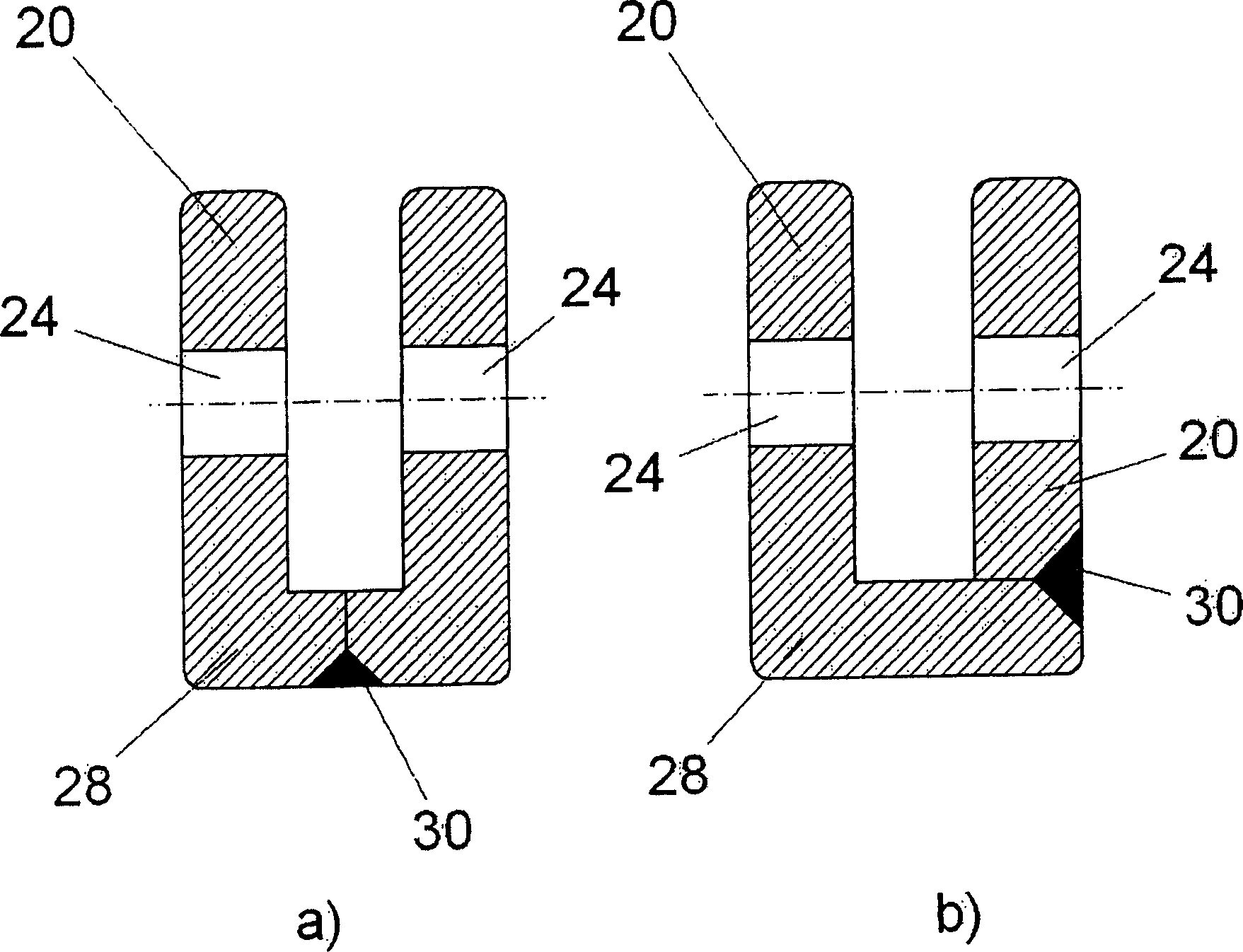

[0033] The needle 10 has a needle hook 16 at its front end. A latch needle groove 18 extending longitudinally is designed in the needle head 10 . The needles form side walls 20 on both sides of the latch needle groove 18 which form the lateral boundaries of the latch needle groove 18 . In a typical case, the width of the needle head 10 measured perpendicularly to the latch needle groove 18 in the area of the latch needle groove 18 is about 0.9 mm. The width of the latch needle groove 18 is about 0.3 mm, so the wall thicknesses of the side walls 20 are respectively about 0.3 mm. The needle latch 12 is rotatably installed in the latch needle groove 18 with its rear end. A pivot pin 22 is used for this purpose, which is rotatabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com