Automatic focusing device for lens

An autofocus and lens technology, applied in focusing device, installation, optics, etc., can solve the problems of complex mechanical structure, large volume, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a further cognition and understanding of the features, purposes and functions of the present invention, the detailed description is as follows in conjunction with the accompanying drawings:

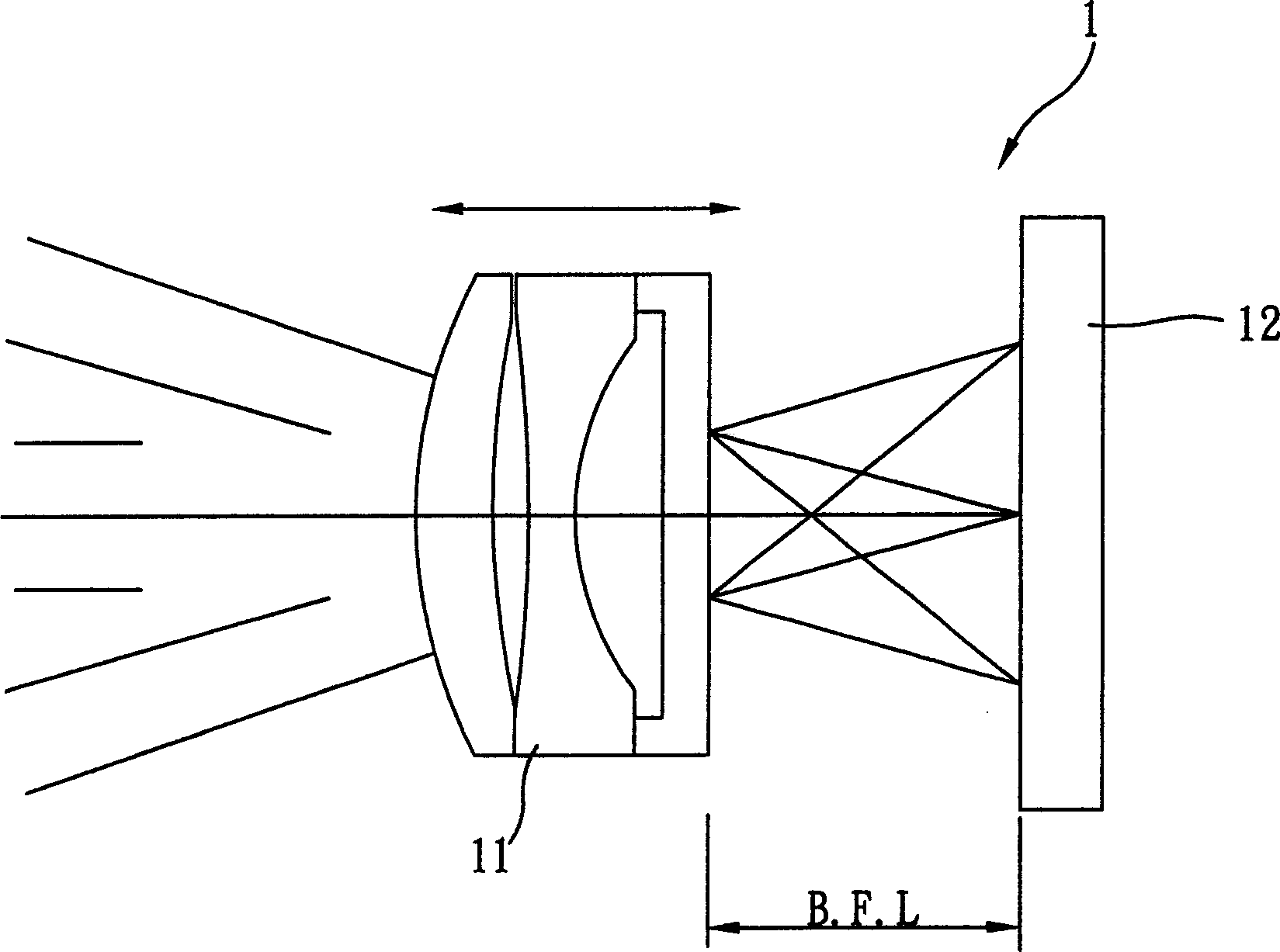

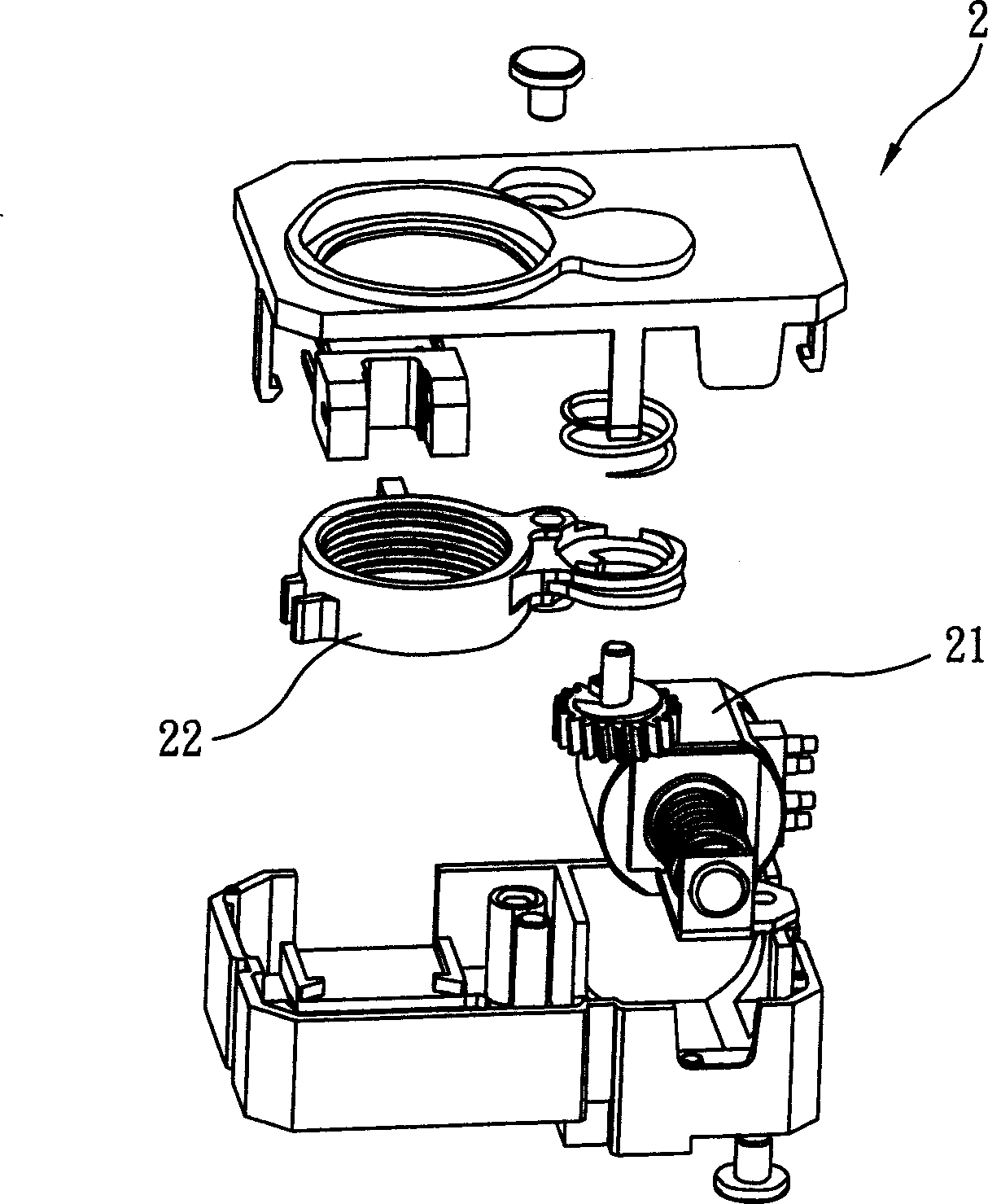

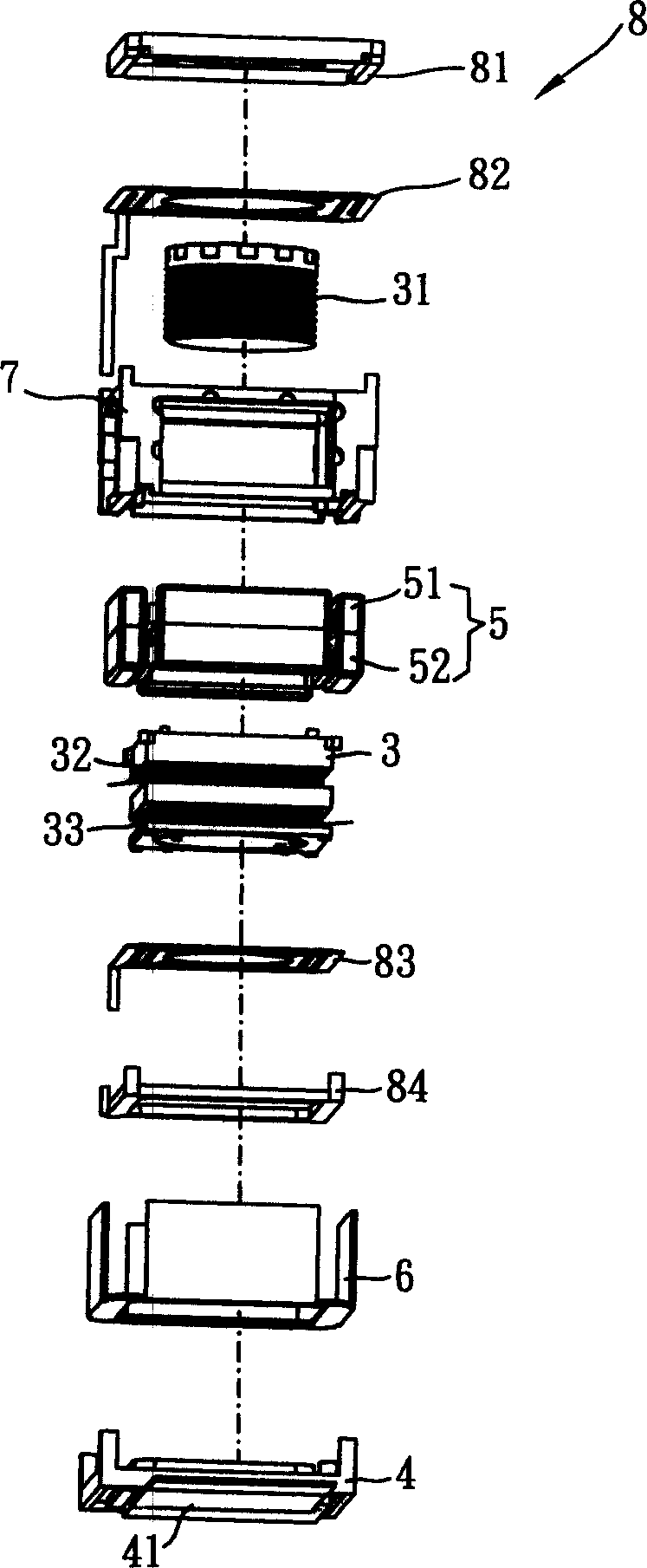

[0017] see image 3 , Figure 4 and Figure 5 , which is a preferred embodiment of the lens autofocus device of the present invention. in, image 3 Shown is a three-dimensional exploded view of the lens auto-focus device of the present invention. Figure 4 It is a schematic diagram of the winding appearance of the lens group seat coil in the lens auto-focus device of the present invention. Figure 5 It is a schematic diagram of the magnetic action in the lens auto-focus device of the present invention.

[0018] Such as image 3 As shown, the lens autofocus device of this embodiment is mainly composed of a lens group holder 3 (Lens-holder), an optical sensor assembly holder 4 (Sensor-holder), a permanent magnet group 5 (Magnets), a yoke 6 ( Yoke) and subject ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com