Method for producing sealing rubber air-bag male die and resin transfer molding method therefor

A technology for sealing rubber and its manufacturing method, which is applied in the manufacture of sealing rubber airbag positive molds and the field of resin transfer molding of complex structural composite material parts, achieving the effects of good industrial applicability, simple process, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

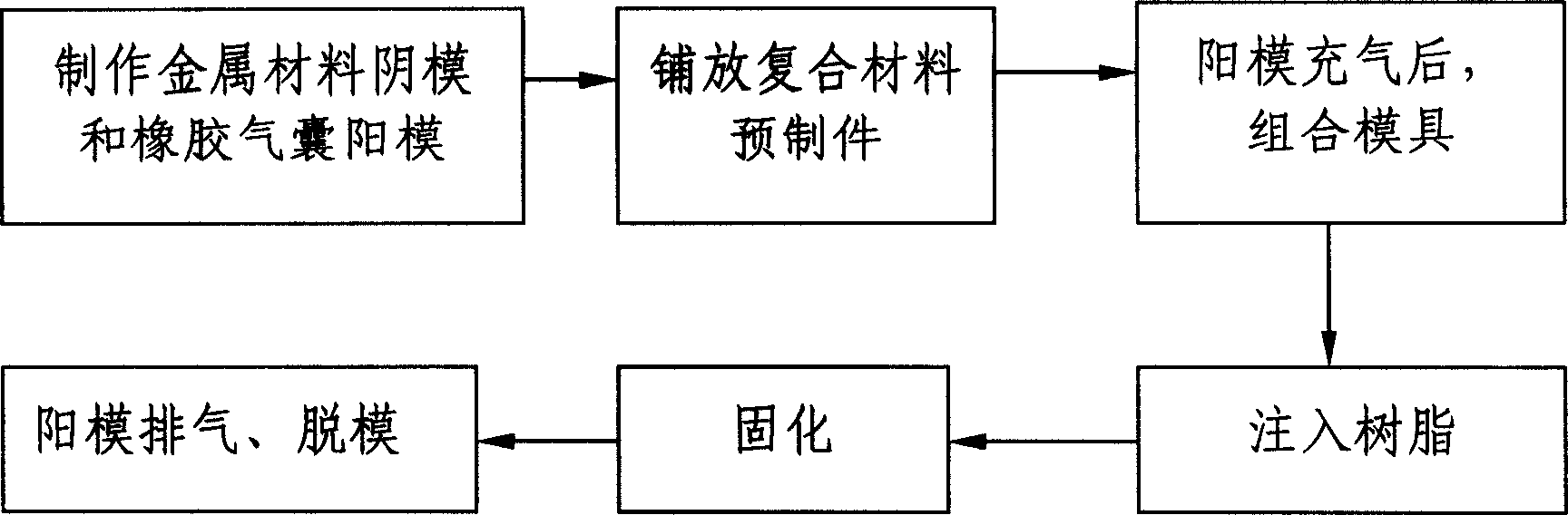

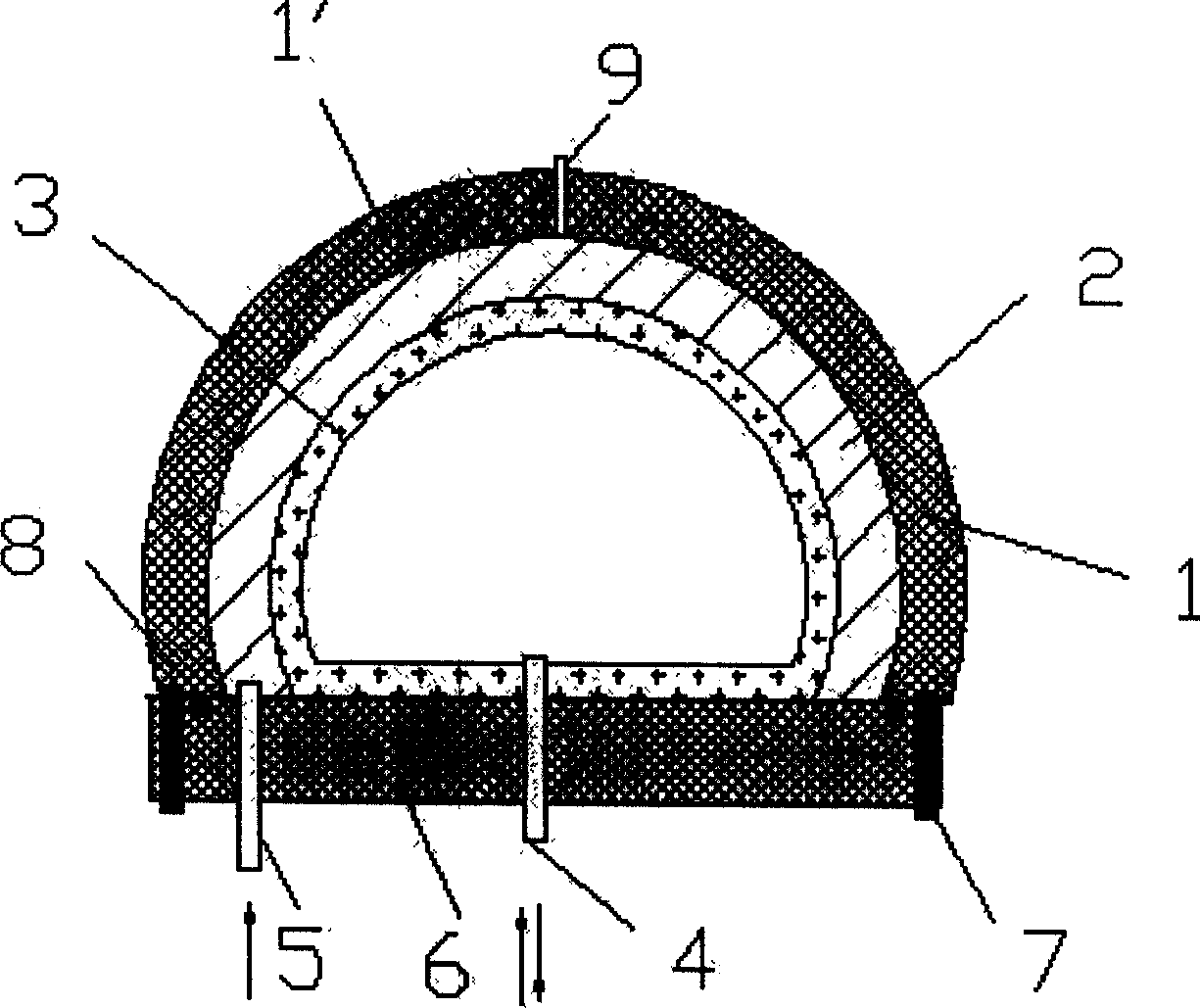

[0019] Manufacturing method of sealing rubber airbag positive mold of large hemispherical composite material parts and new method of RTM forming (see figure 2 ).

[0020] (1) Manufacture the positive mold of the sealed rubber airbag: first, according to the shape requirements of the composite material part, use metal materials to manufacture two symmetrical mold blocks 1 and 1' larger than 1 / 4 spherical shape, and a flat cover plate mold block 6, and three molds Blocks 1, 1' and 6 together form the female mold. Make the hemispherical sealing rubber airbag positive mold 3 of band gas nozzle 4 with rubber sheet material again, make it have deformability and sealing.

[0021] The manufacturing method of the large hemispherical male mold 3 is as follows: first lay the filling material in the metal female modules 1 and 1', the filling material in the embodiment adopts glass fiber fabric, and the laying thickness is not less than the thickness of the composite material part 2 Dim...

Embodiment 2

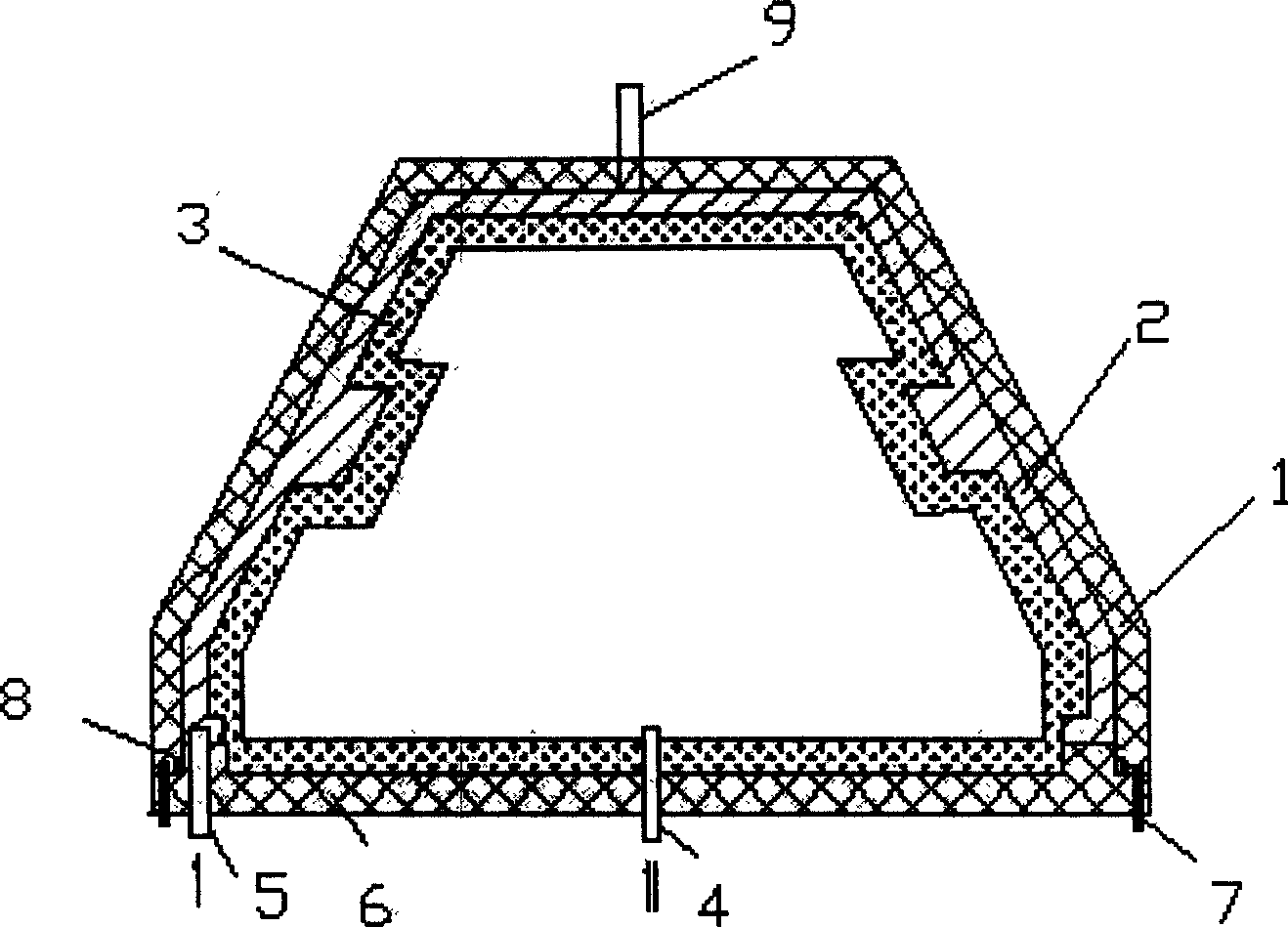

[0024] The sealing rubber air bag positive mold manufacturing method and RTM molding new method of the tapered composite material parts with reinforcing ribs (see image 3 ).

[0025] (1) Manufacture the male mold of the sealing rubber airbag: the manufacturing method of the male mold 3 is basically the same as in embodiment 1. The difference is that there are two metal female molds, one is a female module 1 similar to a trapezoidal cross-section; the other is also a flat cover plate female module 6; and the rubber sheets used are three pieces, and the overlapping length of the rubber sheets When the oven temperature is designed to be 160°C, keep the pressure at 0.2Mpa for 20 minutes to vulcanize the rubber. In addition, the filling material should be well reinforced.

[0026] (2) RTM new method for manufacturing composite parts: place the composite material preform 2 in the metal female module 1, and then put the male mold 3, so that the concave part and the protruding part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com