Transmission type anchoring device

An anchoring device and transmission technology, which is applied in the direction of transportation and packaging, running mechanism, load hanging components, etc., can solve problems such as inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

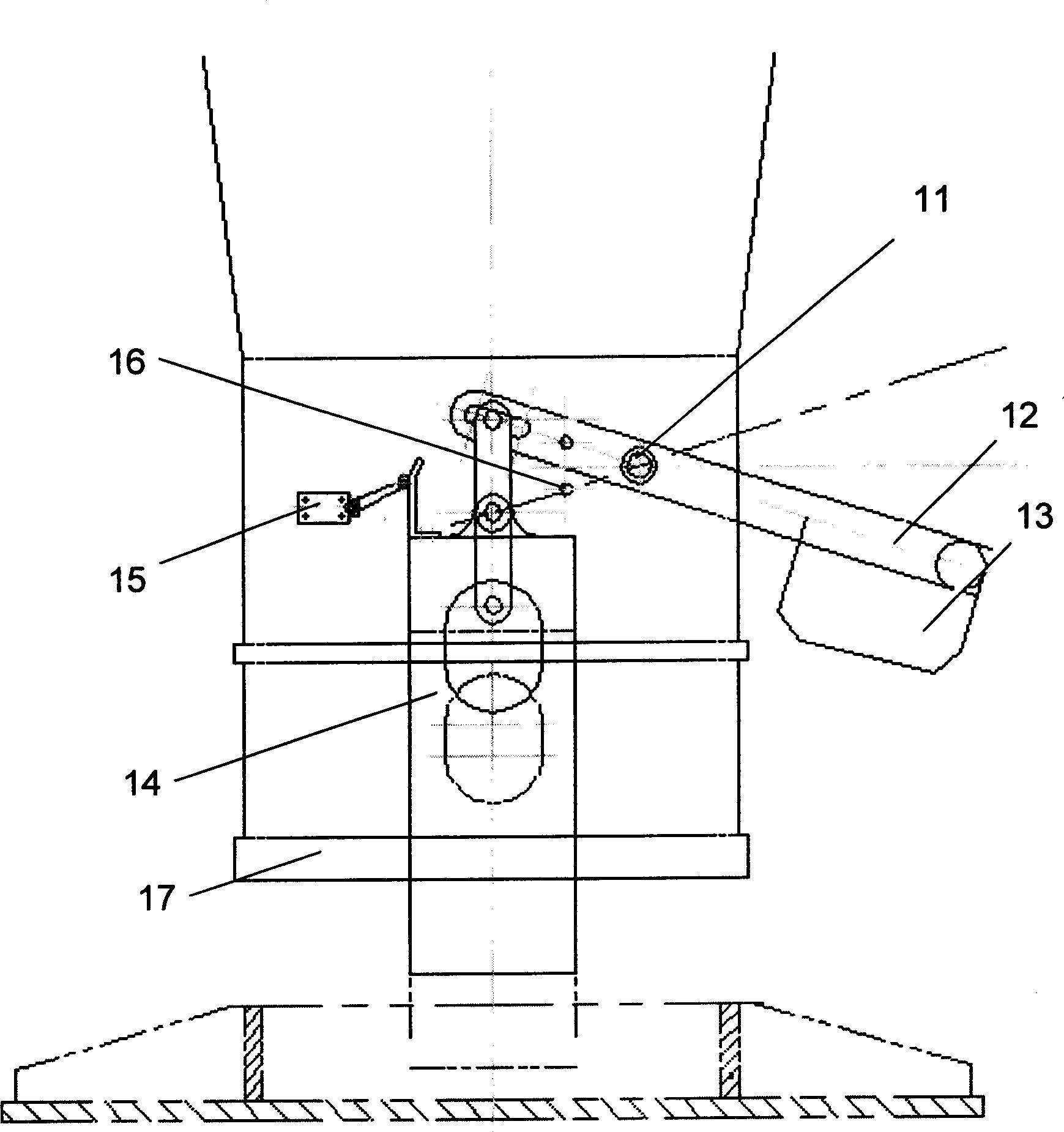

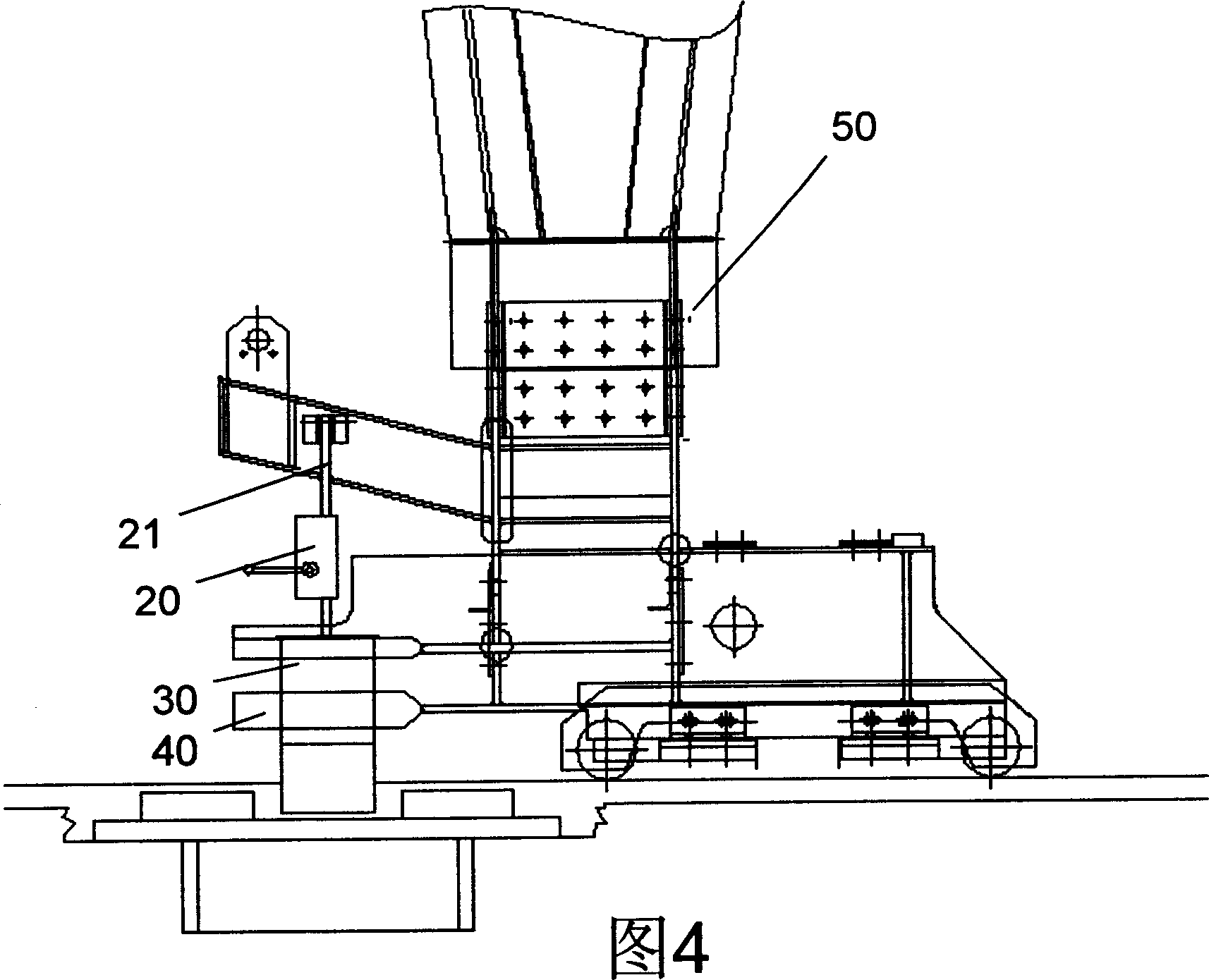

[0027] Please refer to Figure 4 first, Figure 5 As shown, the lifting device 20 , the anchoring plate 30 , and the baffle 40 of the present invention, the lifting device 20 is connected to the anchoring plate 30 , and the baffle 40 is located below the anchoring plate 30 .

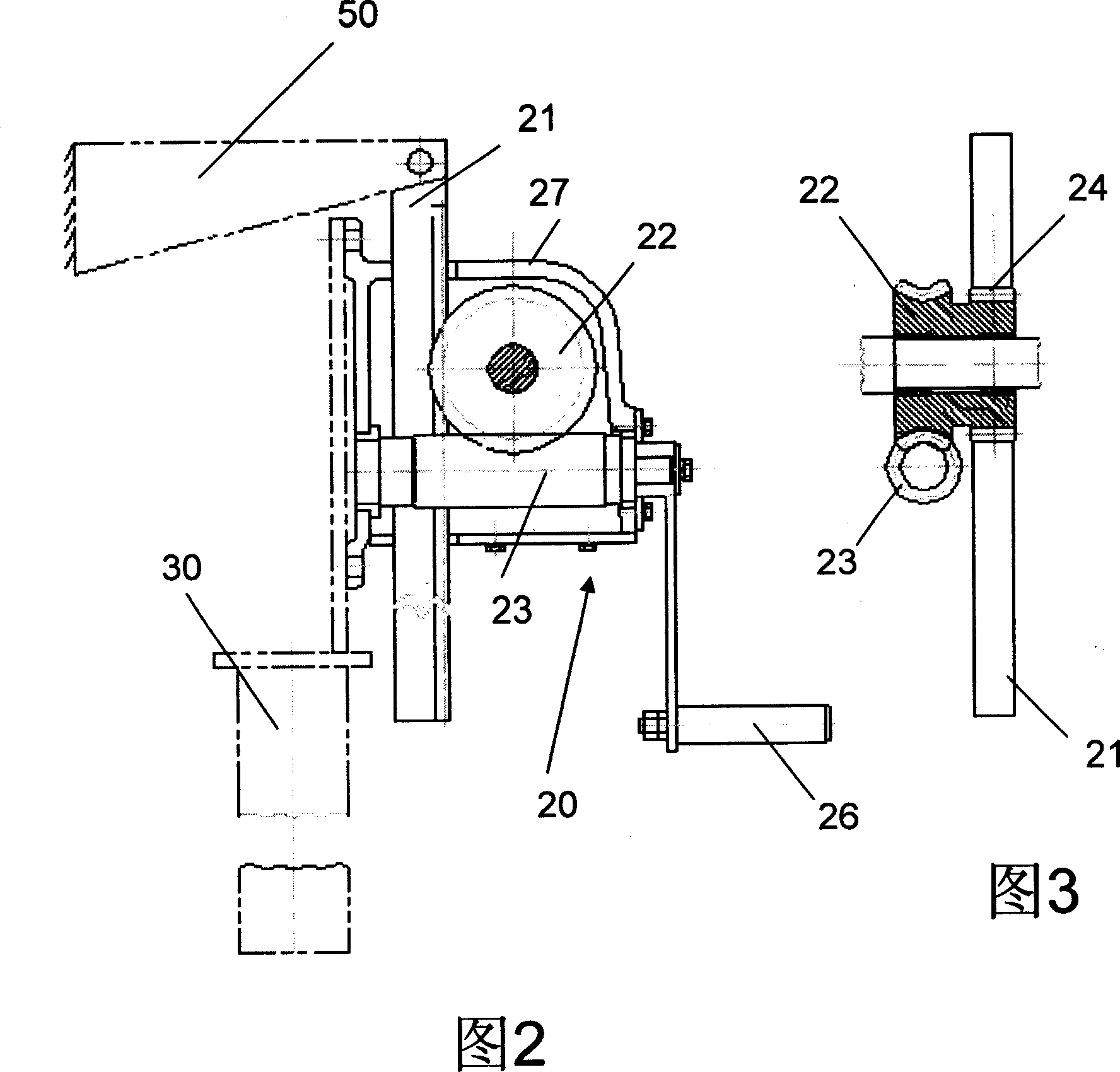

[0028] The lifting device 20 is a closed structure with an outer cover. Please refer to FIG. 2 and FIG. The worm gear 22 and the worm screw 23 form a reduction gear; the worm screw 23 is connected with the rocker arm 26 and fixed on the cover 27 of the lifting device; Engagement; the outer cover 27 of the lifting device 20 is connected with the anchor plate 30 by bolts, so that the outer cover 27 and the anchor plate can move synchronously, of course, other ways can also be used to connect the outer cover 27 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com